An intelligent shredder

A pulverizer, intelligent technology, applied in the direction of dust removal, cleaning methods and appliances, grain processing, etc., can solve the problems of time-consuming and labor-intensive staff, low degree of automation, poor automation process, etc., to save energy and reduce human participation , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

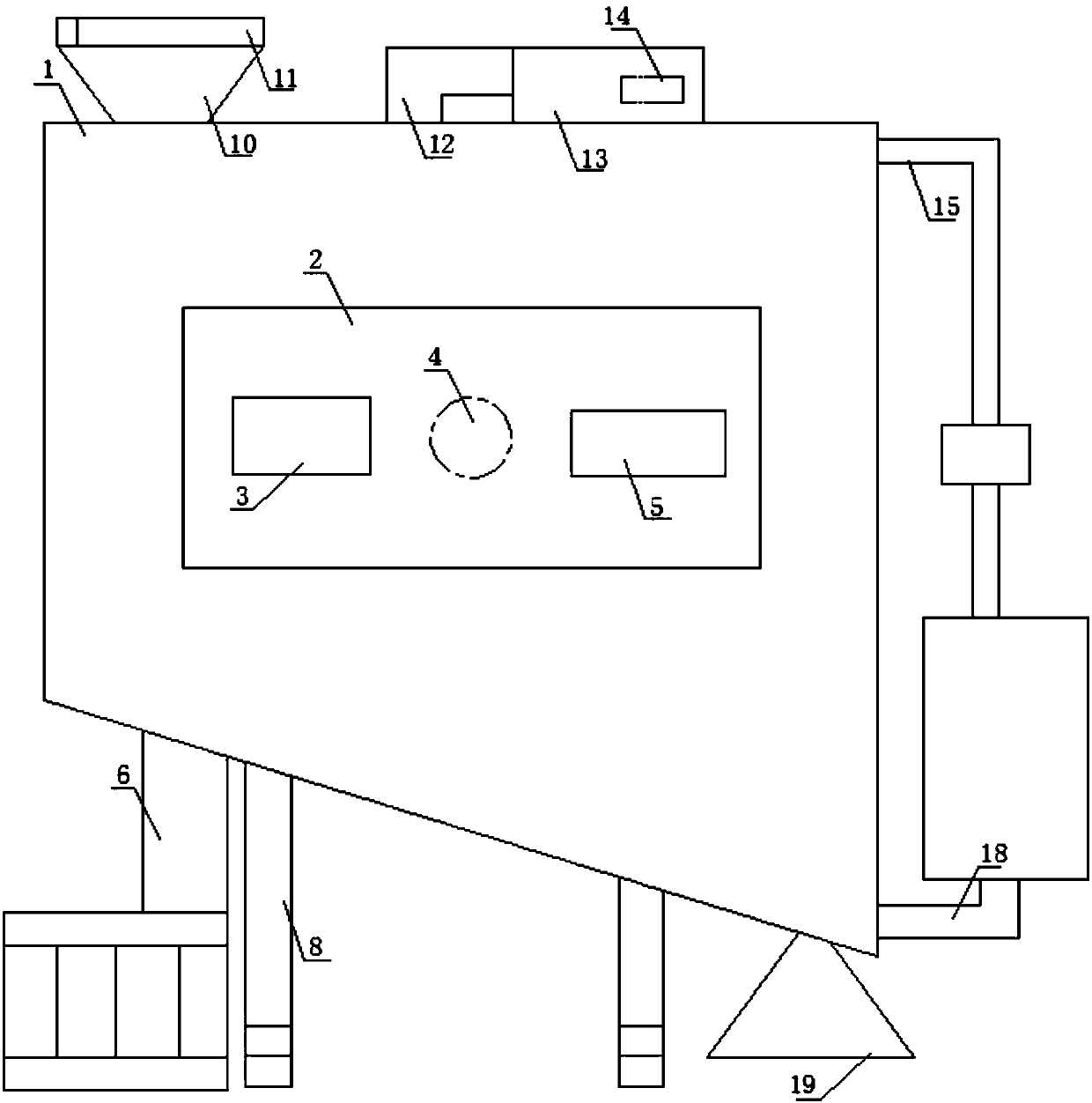

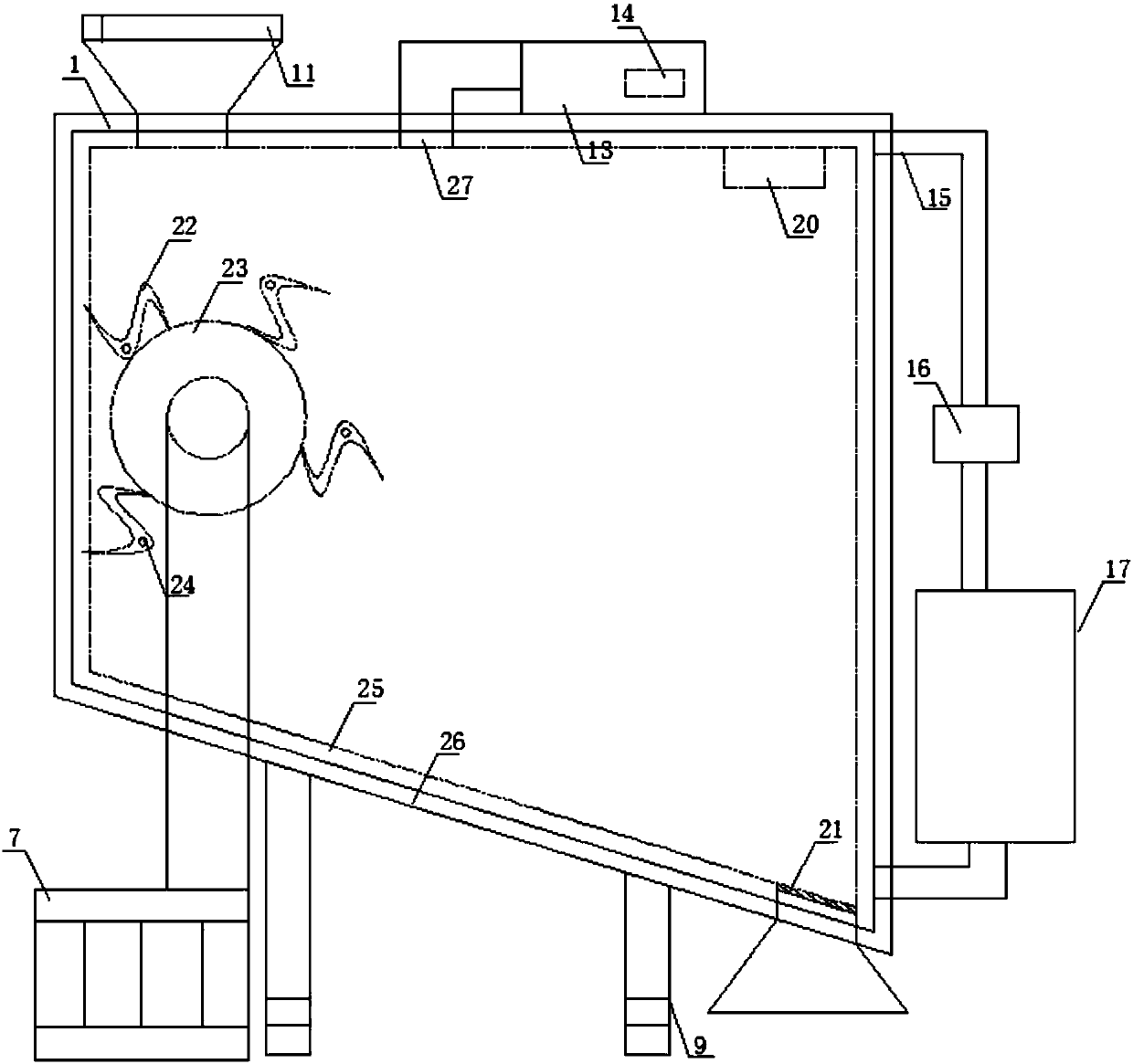

[0026] Such as figure 1 , figure 2 A kind of intelligent pulverizer described, comprises support 8, and body 1 is set on support 8, and feed inlet 10 is set at the upper end of body 1, and discharge port 19 is set at the lower end of body 1, and turntable 23 is set in body 1, and turntable Pulverizer 22 is set on 23, and motor 7 is set outside body 1, and motor 7 is connected with rotating disk 23 by rotating shaft 6; Cooling layer 25 is set in body 1, water inlet 15 and water outlet 18 are set on cooling layer 25, and Cooling water tank 17 is set outside 1, and water inlet 15 and water outlet 18 are all connected to cooling water tank 17 by pipeline, and water pump 16 is set at water inlet 15 places. It can effectively alleviate the heat energy generated by the machine body 1 when crushing materials, improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com