Monitoring device and method for wire web monitoring and wire saw

A measuring device and wire mesh technology, which is applied in the field of sensors for monitoring wire mesh conditions, wire saws for cutting workpieces, and wire mesh condition monitoring in wire saws), can solve problems such as difficult wire meshes to generate accurate images, expensive systems, etc., and achieve The effect of enlarging the effective resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be described with reference to exemplary embodiments and is not limited to a particular wire saw, method or sensor except as defined in the appended claims. Embodiments of the invention can be used in various method and system forms. It will be apparent to those skilled in the art that the present invention can be implemented in various ways within the scope of the claims. All features shown in relation to the figures apply in principle to the invention as described in the claims.

[0079] As used herein, the indefinite article ("a", "an") means that there is at least one of the referenced term and the term "plurality" means that there is more than one.

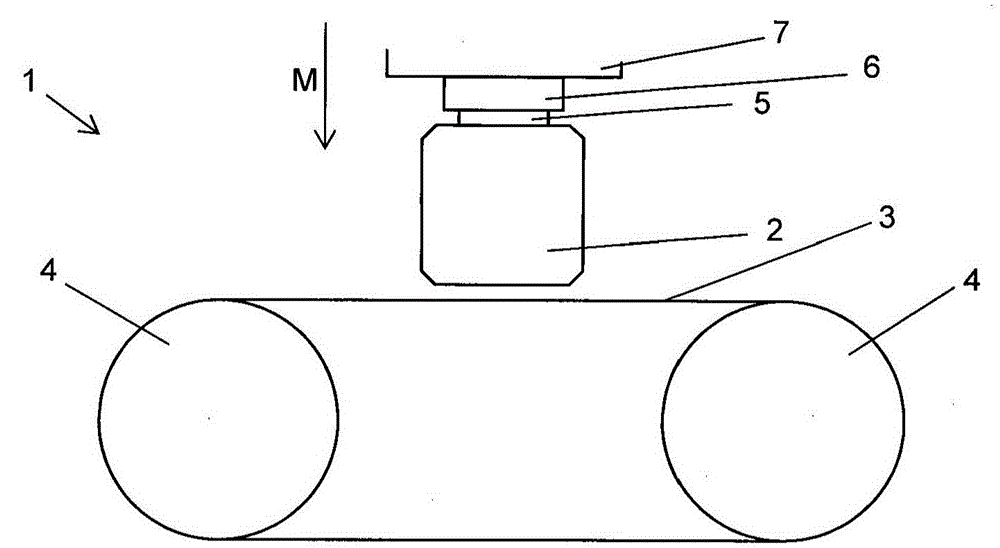

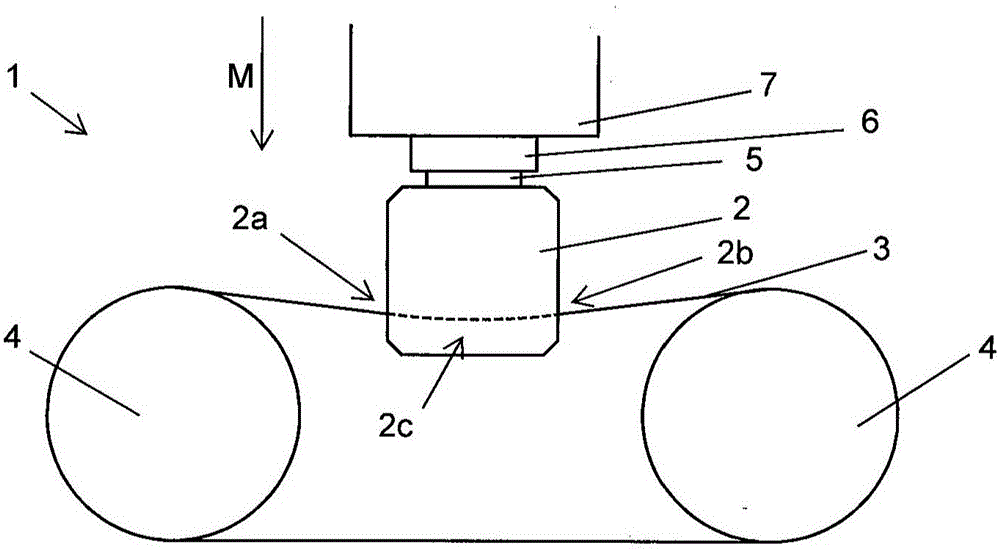

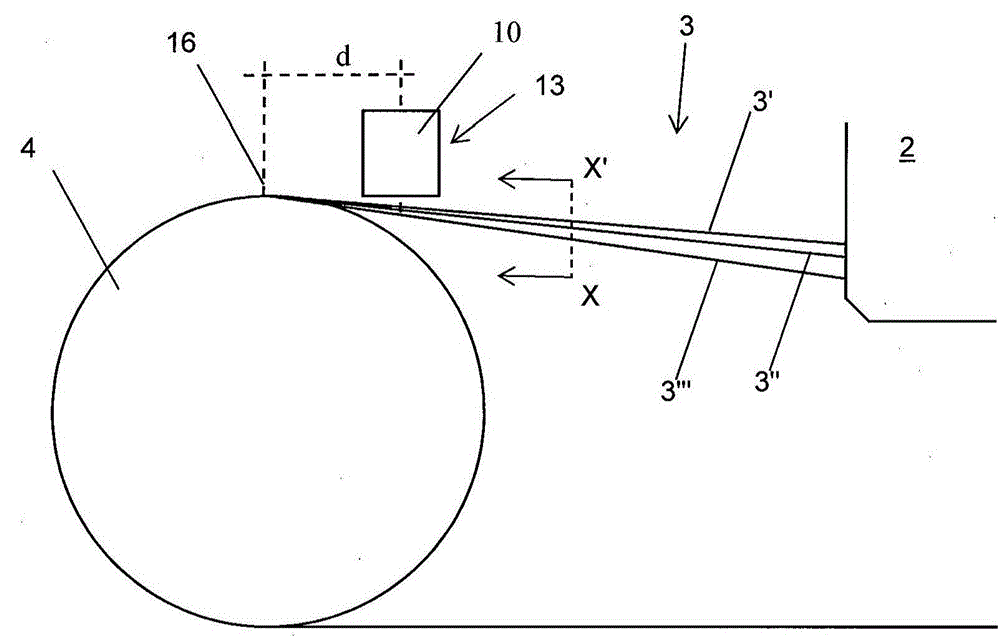

[0080] The present invention relates to systems, methods and production equipment, and more particularly to wire saws, and in particular to multi-wire saws for cutting hard, brittle materials such as silicon, sapphire and quartz, methods for operating such multi-wire saws and their Ingenuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com