Wiper motor end cover employing chrome-plating rust-proof technology

A technology for motor end caps and wipers, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of scrapping and time-consuming, and achieve the effect of ensuring stable connection, prolonging service life and avoiding use accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

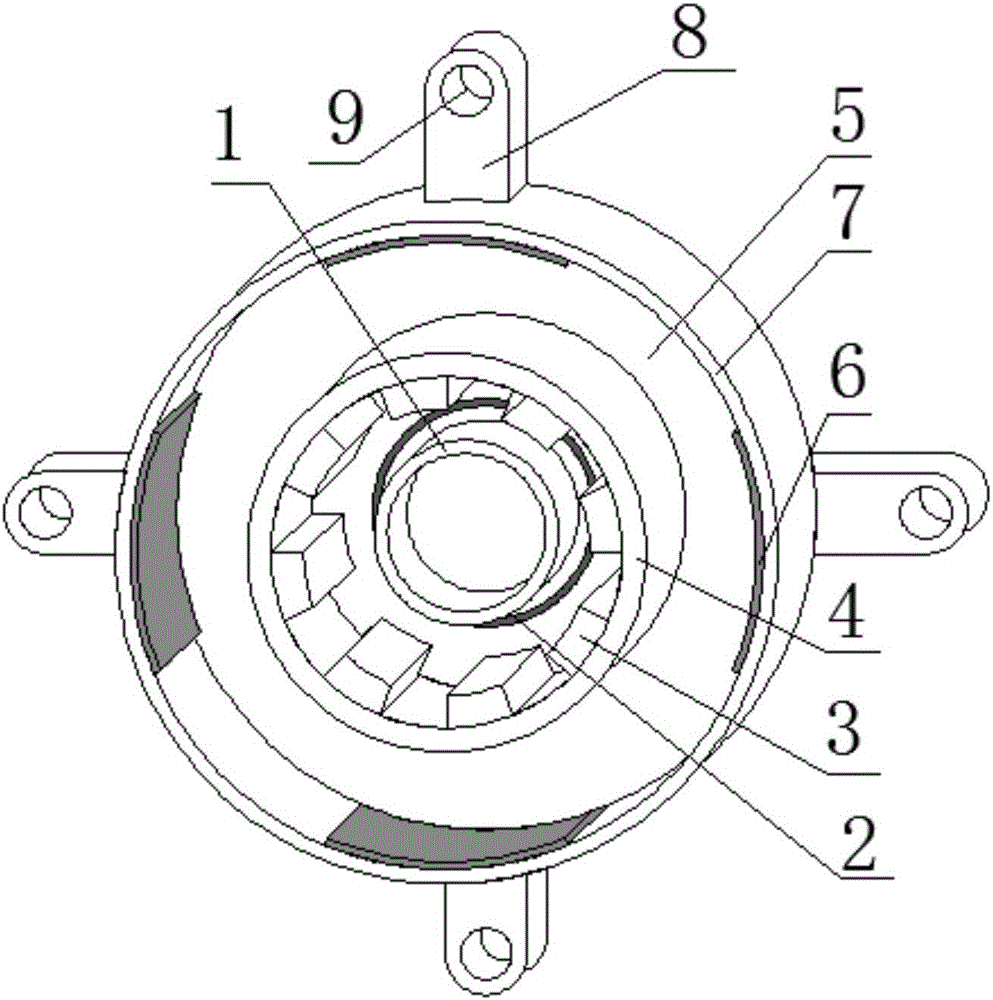

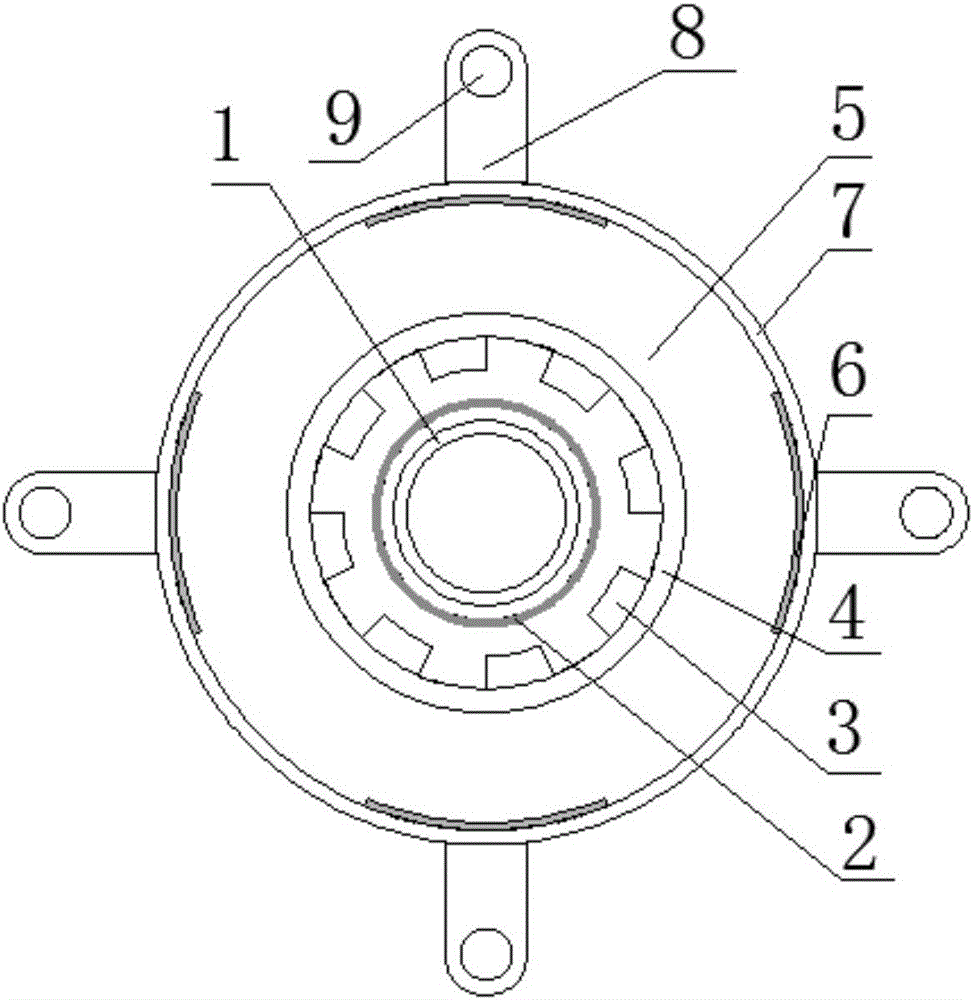

[0026] A wiper motor end cover using chrome-plated anti-rust technology, which solves the problem that in the prior art, it takes a long time to screw the connection between the wiper motor end cover and the wiper motor, and when there is a trace of thread slippage, the entire thread will be announced. For the inadequacy of scrapping, we designed a wiper motor end cover that uses a threaded segment structure for screwing. Its segmental design mode can ensure that even if there is a thread slippage, the entire screwed part will not be scrapped. situation occurs; because the thread segments do not interfere with each other, when a certain thread slips in a certain section, the entire screw connection will not be scrapped; and the use of straight threads instead of ordinary threads makes the screw connection more stable and There will be no deformation, such as figure 1 , figure 2 As shown, it includes the wiper motor end cover body that has been treated with plating and anti-r...

Embodiment 2

[0030] This embodiment is further optimized on the basis of the above-mentioned embodiments. Further, in order to better realize the present invention, the connection between the wiper motor and the end cover of the wiper motor can be more in line with mechanical stability, such as figure 1 , figure 2 As shown, the following structure is particularly arranged: the straight threaded sections 6 are 4 sections, and the 4 straight threaded sections 6 are evenly distributed along the circumference of the outer cylinder 7 of the end cover of the wiper motor.

Embodiment 3

[0032] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, and further ensure a stable connection with the stator or rotor in the wiper motor, such as figure 1 , figure 2 As shown, the following structure is particularly arranged: the wiper motor end cover body is also provided with a wiper motor end cover inner cylinder 4, and the wiper motor end cover inner cylinder 4 and the wiper motor end cover outer cylinder 7 is concentrically arranged on the bottom 5 of the end cover of the wiper motor; on the inner wall of the inner tube 4 of the end cover of the wiper motor, a circle of bosses 3 which are geometrically evenly distributed is arranged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com