A heat dissipation structure of the current-carrying conductor in the center of an ultra/ultra-high voltage dry bushing

A technology of current-carrying conductors and dry-type bushings, which is applied in the direction of conductors, insulated conductors, and insulated cables. Reliability, wide application range and reasonable heat dissipation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

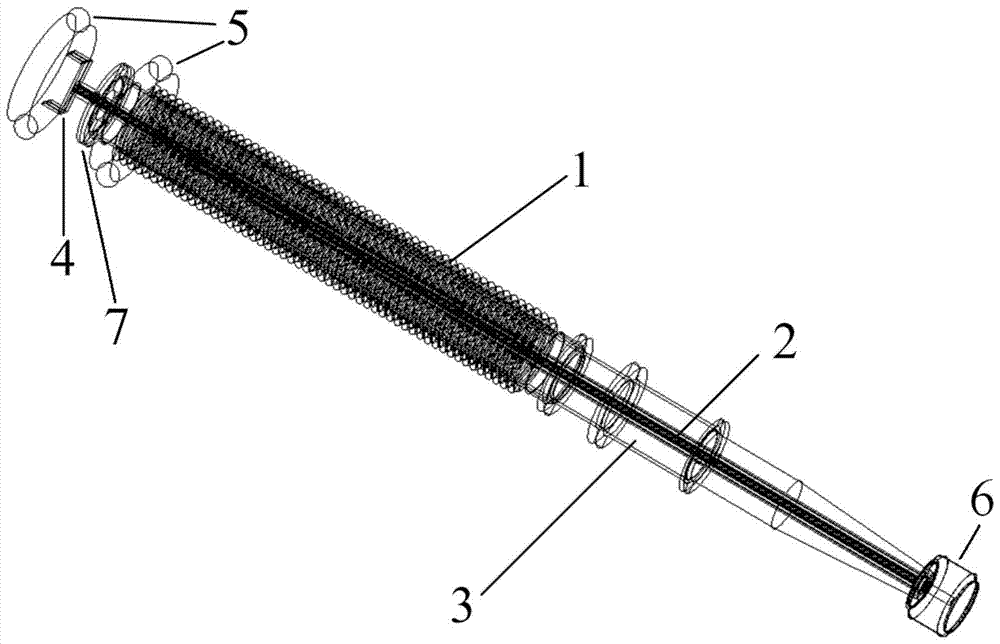

[0022] Such as figure 1 As shown, the EHV / UHV dry bushing is mainly composed of a sheath 1, a current-carrying conductor 2, a core 3, a connecting fitting 4, a pressure equalizing ring 5, a pressure equalizing ball 6, and a cover plate 7. Wherein, the current-carrying conductor 2 is located at the center of the dry bushing, the outer side of the current-carrying conductor 2 is the core 3, the outer side of the core 3 is the sheath 1, and the current-carrying conductor 2 extends out of the cover plate 7 and the end of the bushing. The connecting fittings 4 are connected, the pressure equalizing ring 5 is connected with the connecting fittings 4 through a bracket, and the equalizing ball 6 is installed at the tail of the bushing and connected with the current-carrying conductor 2 .

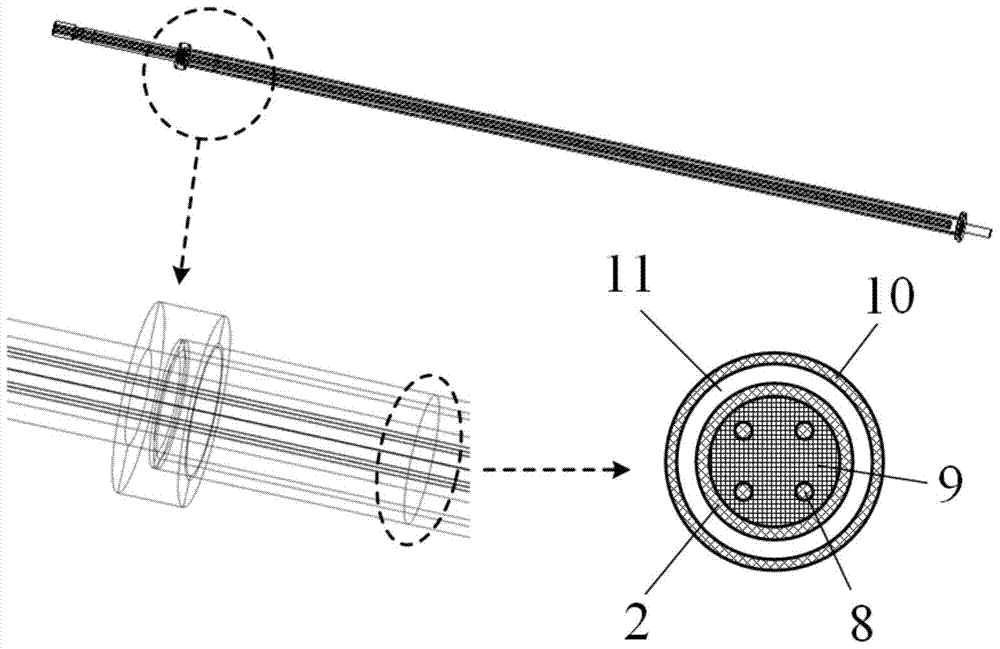

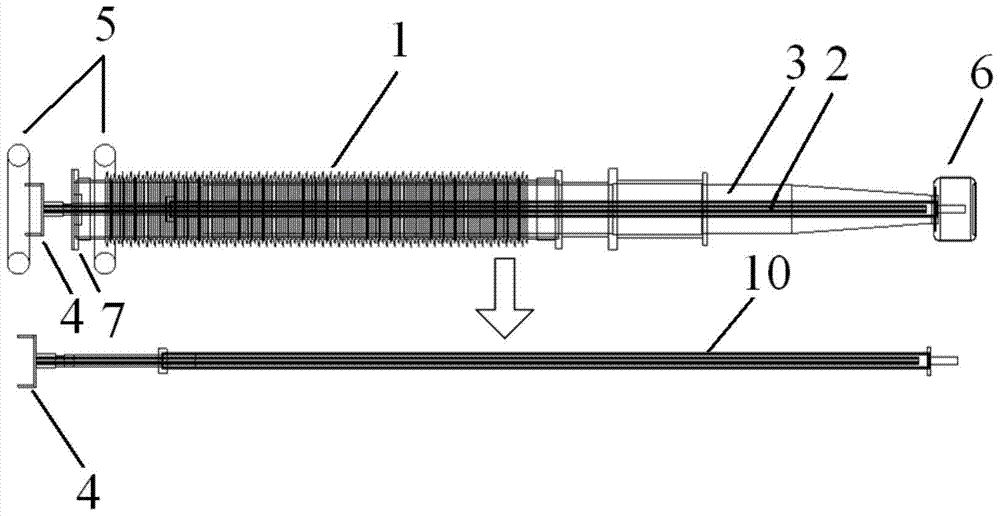

[0023] Such as figure 2 , image 3 As shown, the heat dissipation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com