thermal protector

A protector, over-temperature technology, applied in protection switches, emergency protection devices, parts of protection switches, etc., can solve the problems of over-temperature protectors being large in size and being easily affected by external forces, avoiding instantaneous disconnection of vibration, eliminating The effect of reducing the number of transmission links and parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

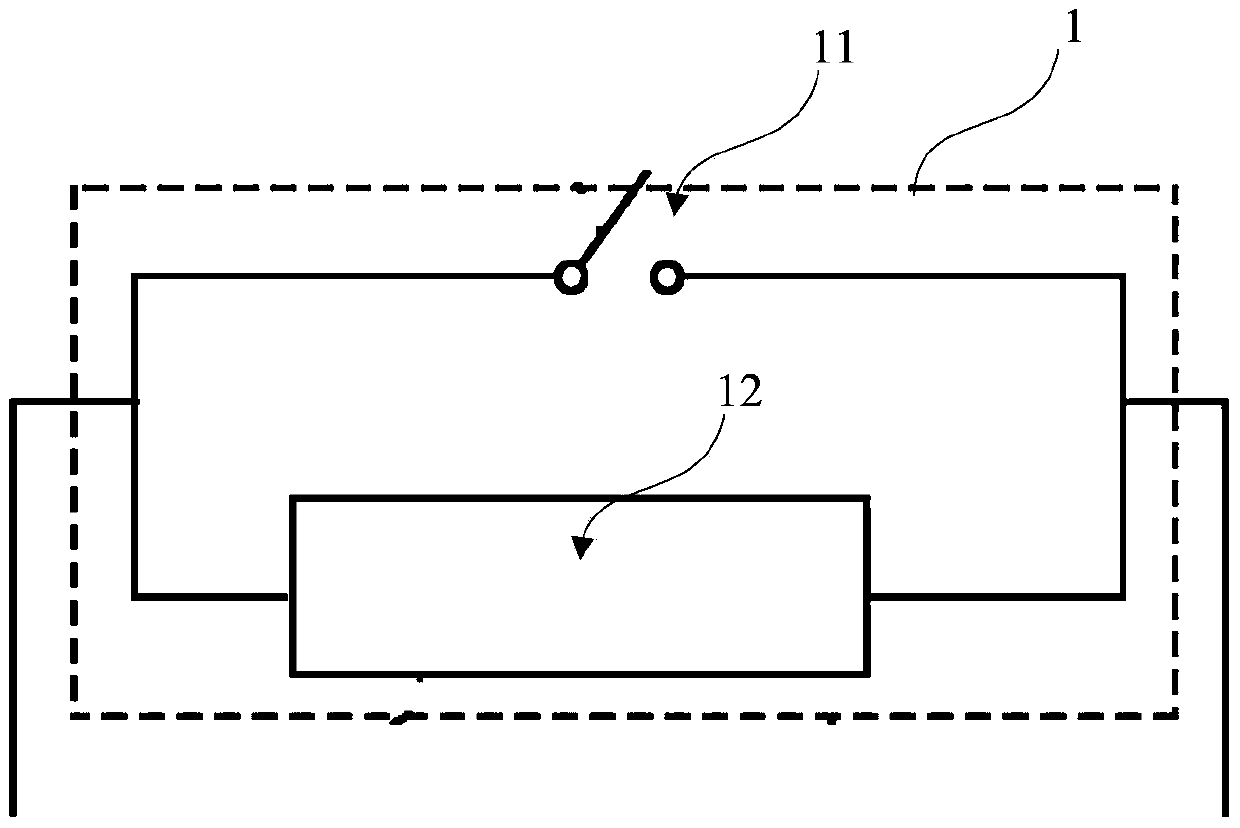

[0067] Such as figure 2 As shown, the working circuit 1 of the over-temperature protector of the present invention adopts a mode in which a heat-driven switch 11 and a heating element 12 are connected in parallel. Wherein the heat-actuated switch is made of temperature-sensitive material, the heat-actuated switch is closed under normal temperature state, and the heat-actuated switch is opened under high temperature state. The thermally actuated switch can change rapidly within the set temperature range, and complete the shape change to realize the circuit opening and closing. The heating element continues to generate heat after the drive switch cuts off the circuit, and the heat emitted by it prevents the heat drive switch from closing.

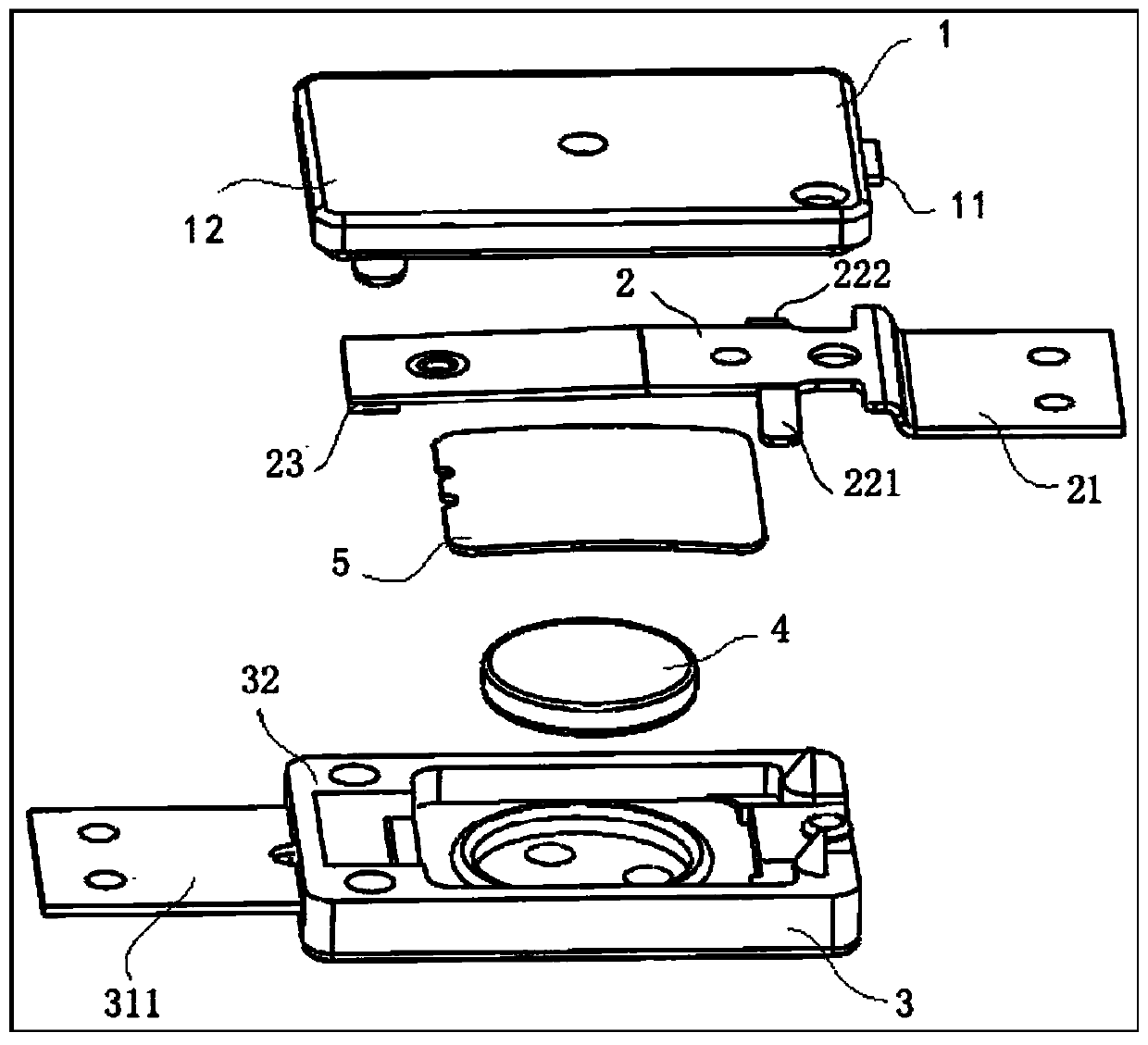

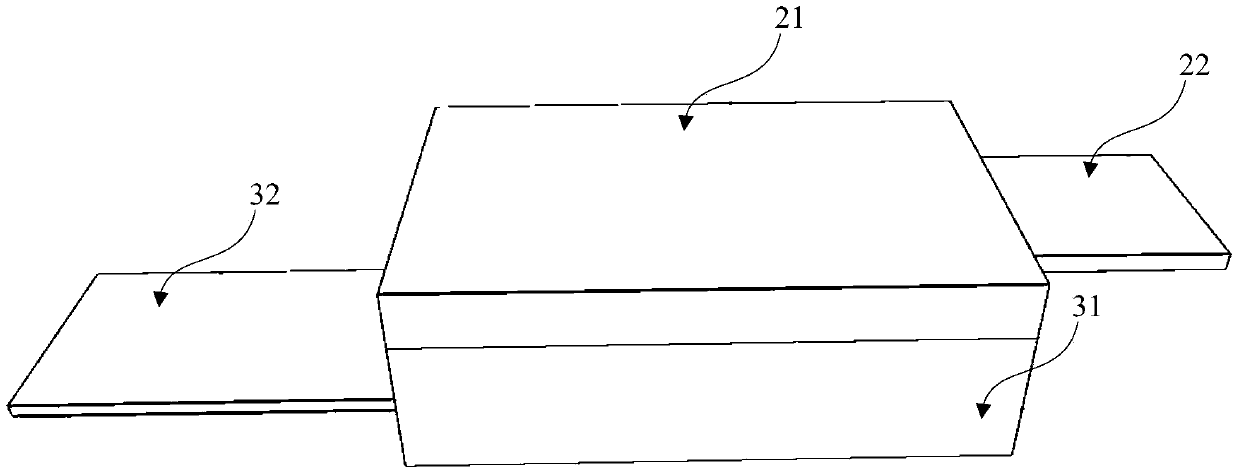

[0068] Such as Figure 2 to Figure 8 As shown, this embodiment provides an over-temperature protector, the over-temperature protector includes a heating element, a driving arm, a first contact structure, and a second contact structure, and...

Embodiment 2

[0079] Such as Figure 9 ~ Figure 14 As shown, this embodiment provides an over-temperature protector, the basic working principle and basic structure of the over-temperature protector are as in embodiment 1, wherein, compared with embodiment 1, the improvement is that the driving arm is embedded and fixed In this way, it is more beneficial to improve the heat transfer efficiency of PPTC to the driving arm and the structural strength of the fixing of the driving arm.

Embodiment 3

[0081] Such as Figure 15 ~ Figure 16 As shown, this embodiment provides an over-temperature protector, the basic working principle and basic structure of the over-temperature protector are as in embodiment 2, wherein, compared with embodiment 2, the improvement is that the heating element groove 33 The geometric design with the driving arm slot 34 is more beneficial to improve the heat transfer efficiency of the PPTC to the driving arm and provide the driving arm with a certain range of motion.

[0082] Such as Figure 15 As shown, the over-temperature protector restricts the driving arm slot 34 so that the driving arm will not deform too much when the external temperature fluctuates greatly, thereby limiting the movable range of the driving arm, causing damage to the placement structure and reducing sensitivity.

[0083] Such as Figure 16 As shown, the overtemperature protector combines the heating element groove 33 and the driving arm groove 34 into one to form an overal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com