Space analytic geometry-based line-scan camera calibration method

A space analytic geometry, line scan camera technology, applied in the field of line scan CCD camera calibration, can solve the problems of many special requirements, complex target production, and low calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention is further described below in conjunction with the accompanying drawings, but the scope of the present invention is not limited in any way.

[0055] Concrete implementation process of the present invention is as follows:

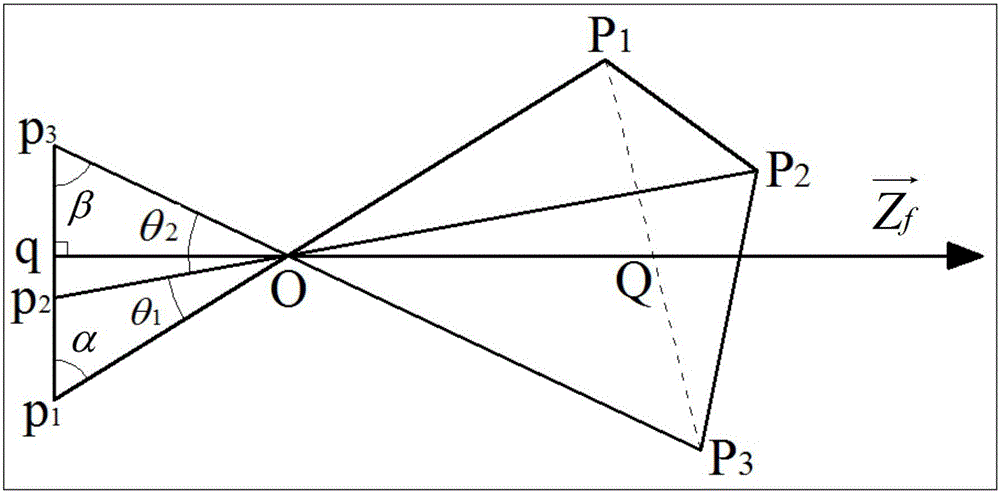

[0056] First design and make the target, and then calibrate the internal and external parameters of the line scan camera. The parameters include: the principal point of the image U 0 , the focal length f and the optical axis vector of the camera

[0057] 1. Operation process of line scan camera calibration

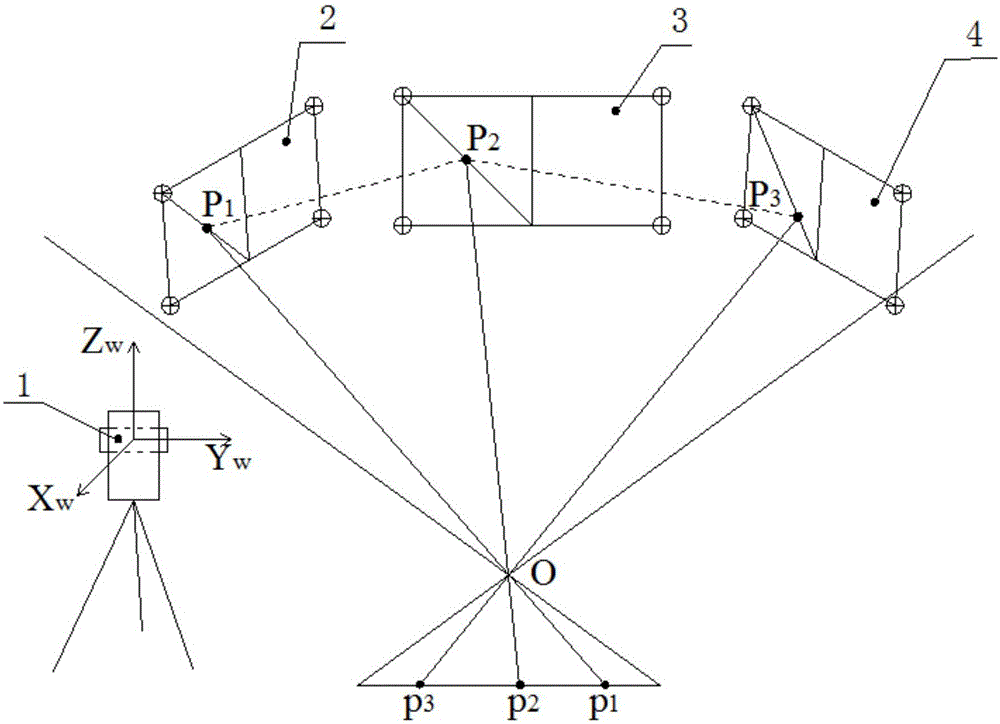

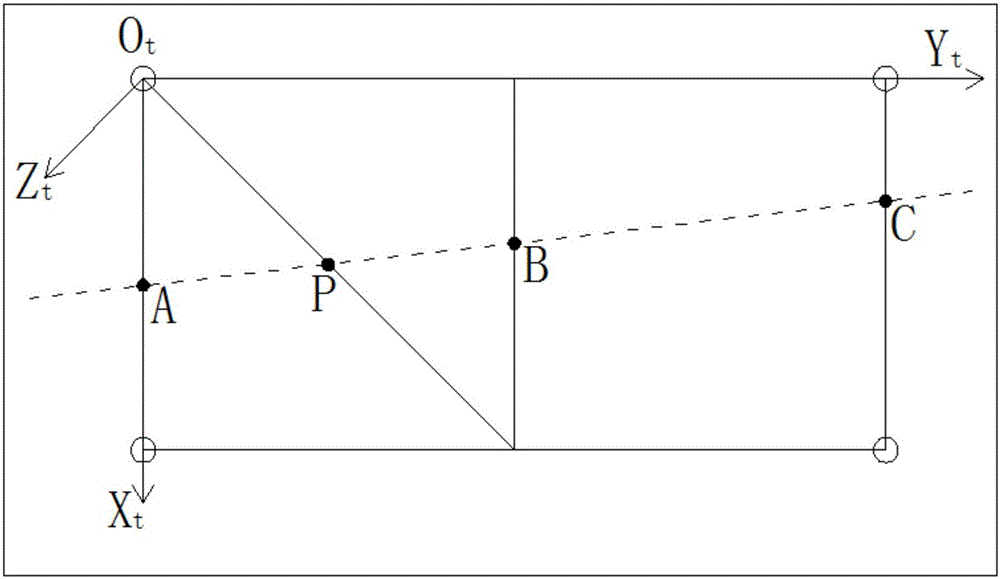

[0058] (1) Design and make a target. After analysis and experimentation, the final design of the target is as attached figure 2 As shown, finally make 3 identical targets.

[0059] (2) Use the total station as a third-party tool to establish a world coordinate system.

[0060] (3) Use the total station to measure the coordinate O=(XYZ) of the optical center O of the camera in the world coordinate system.

[0061] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com