Method for detecting composite insulator based on multi-spectrum

A composite insulator and detection method technology, applied in the field of composite insulator detection based on multi-spectrum, can solve problems such as inability to effectively discover and judge composite insulators, and achieve the effect of convenient inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A method for detecting composite insulators based on multi-spectrum, specifically comprising:

[0028] 1) Under suitable external conditions, select suitable visible light, infrared and ultraviolet detection equipment.

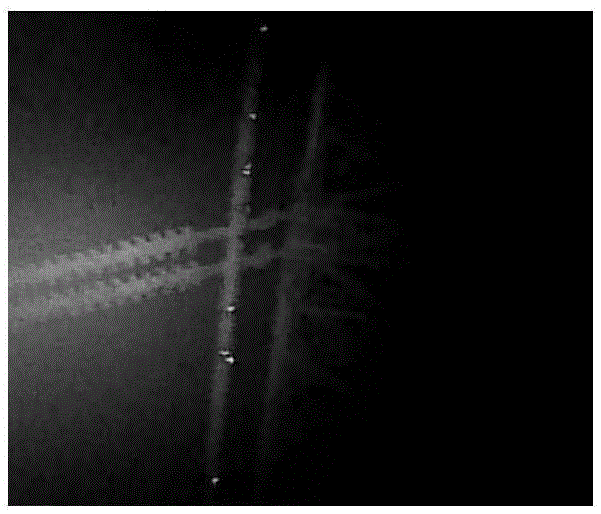

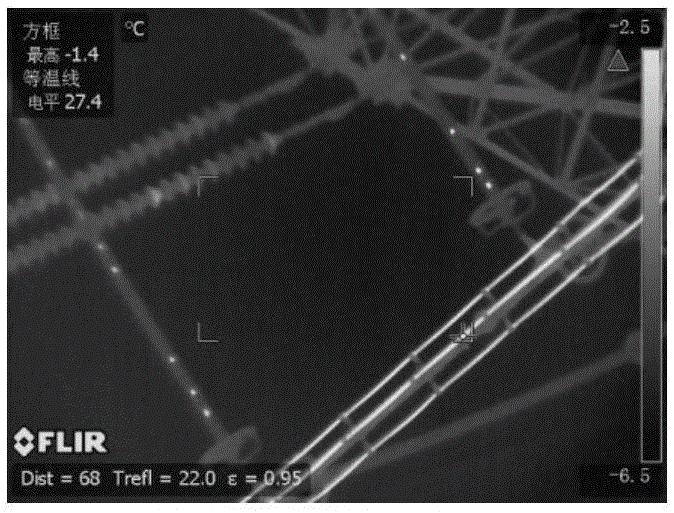

[0029] 2) Under the same operating conditions, carry out visible light, infrared and ultraviolet detection on the key detection parts of the same composite insulator,

[0030] 3) The visible light image, infrared image and ultraviolet image are compared horizontally, and the operation status of the inspected composite insulator is comprehensively compared and analyzed.

[0031] 4) Under the same operating conditions, compare different composite insulators or different parts of the same composite insulator on the same base tower of the same line. Longitudinal comparison of visible light images, infrared images and ultraviolet images, comparing the number of photons or ultraviolet images generated by corona activities in corresponding parts, using the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com