Concrete friction coefficient determination method and device

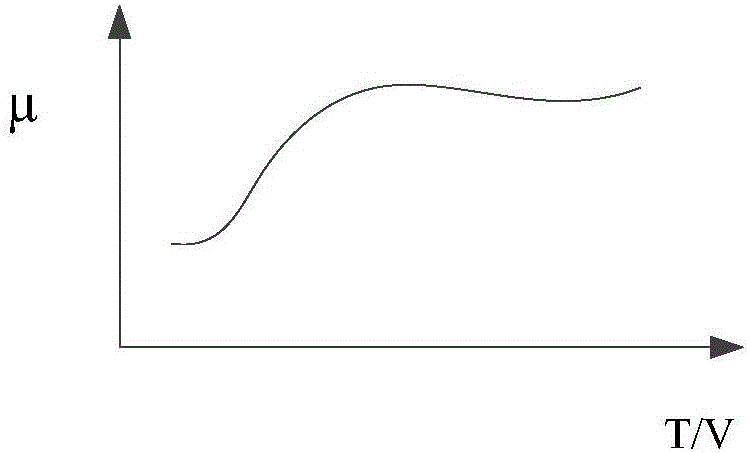

A friction coefficient and measuring device technology, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problem of poor applicability, failure to reflect the loss of concrete slump and expansion over time, and failure to consider the rheological characteristics of the lubricating layer and other issues, to achieve the effect of convenient setting and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Present embodiment one provides a kind of assay method of concrete friction coefficient, comprises the following steps:

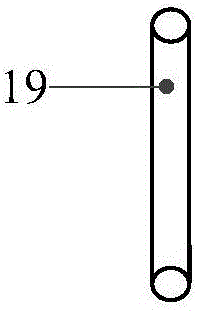

[0028] Step 1, pouring concrete 10 with a preset mass of m kilograms into a concrete pump pipe 11 with a length of L meters and a radius of R millimeters, inserting and tamping the concrete 10 by inserting a tamping rod 19, so that the Concrete 10 is more uniform and dense;

[0029] Step 2, during the process from the beginning of the fall of the concrete 10 in the concrete pump pipe 11 to the end of the fall, the pressure Pi of the concrete 10 in the concrete pump pipe 11 on the inner wall of the concrete pump pipe 11 at any time i second is measured by the pressure sensor 13 Pascal;

[0030] Step 3, during the process of the concrete 10 in the concrete pump pipe 11 falling from the beginning to the end of the drop, measure the falling speed Vi m / sec of the concrete 10 in the concrete pump pipe 11 at any moment i second by the speedometer 15;

[0...

Embodiment 2

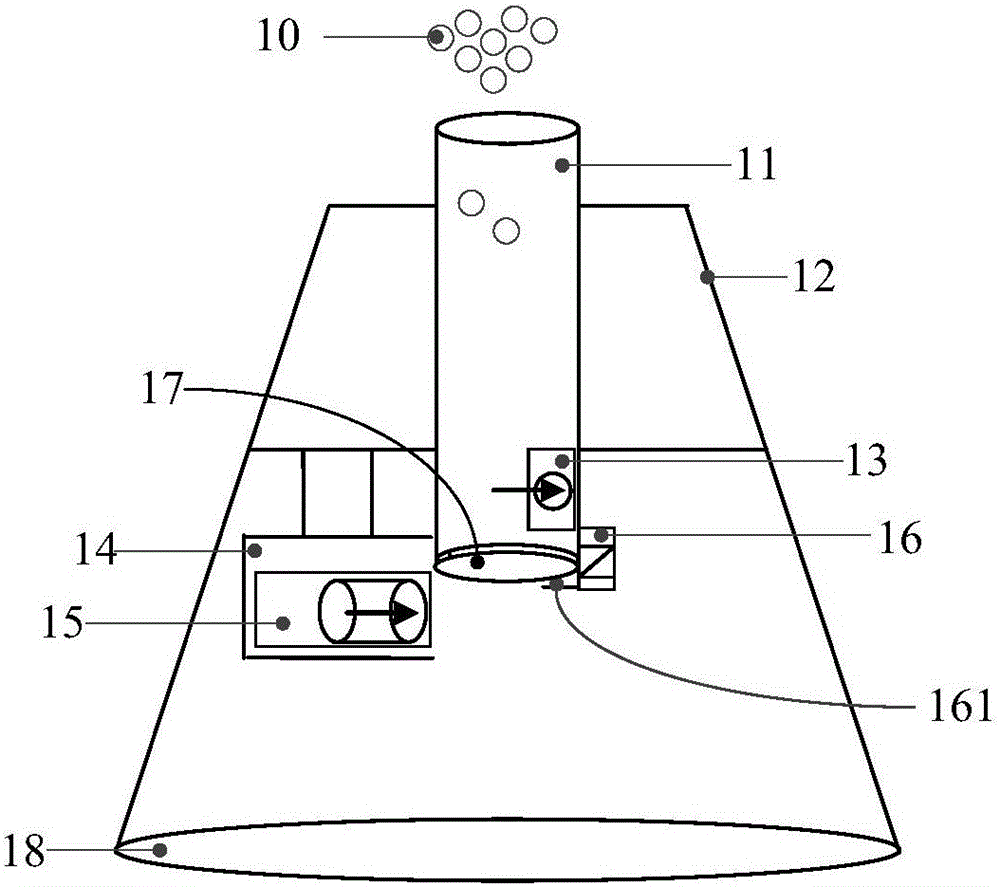

[0039] Please refer to figure 1 , figure 2 , the present embodiment 2 is based on the concrete friction coefficient measuring device set based on the concrete friction coefficient measuring method of implementation 1, comprising a concrete pump pipe 11, which is fixedly connected with a support 12 with the concrete pump pipe 11, and the concrete pump pipe 11 The inner wall is provided with a pressure sensor 13, the pressure sensor 13 is provided near the outlet end of the concrete pump pipe 11, the bracket 12 is provided with a bracket 14, and the bracket 14 is provided with a speedometer 15, the The velocimeter 15 is aimed at the outlet end of the concrete pump pipe 11, and the outer wall of the outlet end of the concrete pump pipe 11 is provided with a probe type timing switch 16, and the probe 161 of the probe type timing switch 16 is arranged on the Below the outlet end of the concrete pump pipe 11; it also includes a hopper door 17 arranged at the outlet end of the concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com