Online section scanner of tyre surface

A scanning device and tread technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that the quality of the tread section cannot be truly reflected, and the manual inspection takes a long time, so as to improve the quality of the tread and shorten the The effect of detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

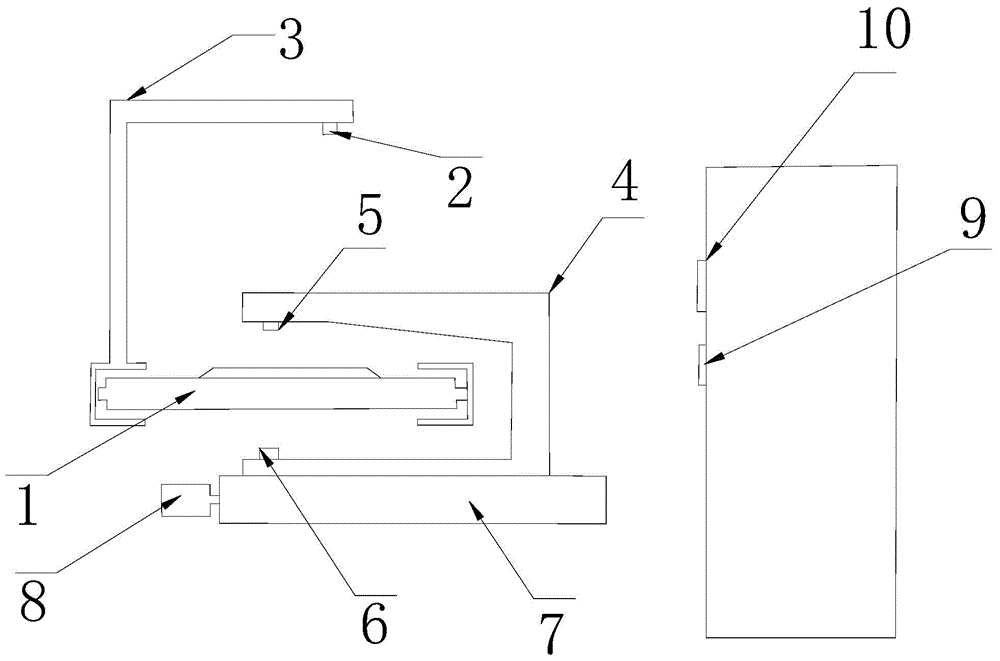

[0009] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] Such as figure 1 Shown is an on-line scanning device for tread cross-section, which is installed on the conveying roller table 1 after the fixed-length cutting. The device includes a photoelectric sensor 2, a first bracket 3, a second bracket 4, a servo motor 8, The controller 9 and the display 10, the photoelectric sensor 2 is arranged above the conveying roller table 1 through the first bracket 3, the photoelectric sensor 2 detects whether the tread reaches the detection position, and the second bracket 4 The first laser thickness measuring sensor 5 and the second laser thickness measuring sensor 6 are respectively arranged at both ends of the two ends, and the first laser thickness measuring sensor 5 and the second laser thickness measuring sensor 6 are respectively located at the upper and lower ends of the conveying r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com