A movable tooth type double clutch

A dual-clutch, movable tooth technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of insufficient torque, low reliability and high process requirements, and achieve low shifting power loss, high working efficiency, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

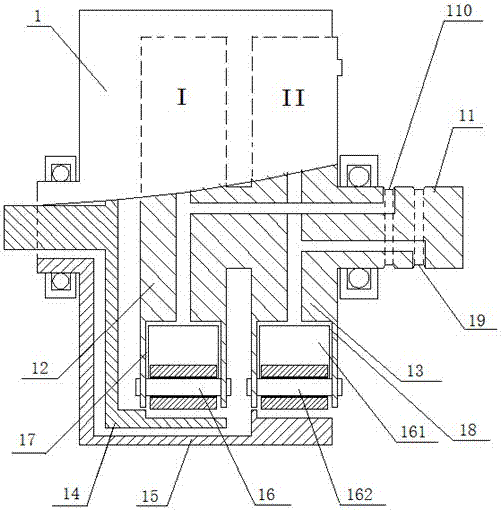

[0027] See Figure 5 , a movable tooth type double clutch, including a double clutch body 1, a high pressure oil unit 2 and a control unit 3;

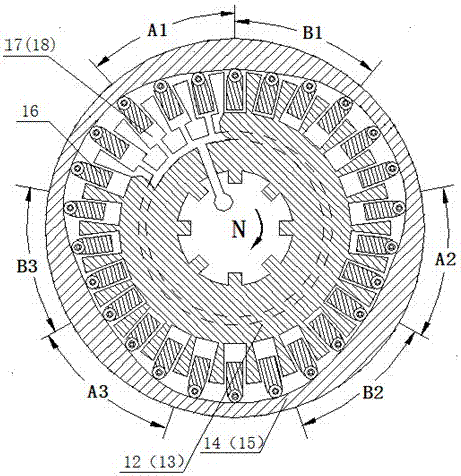

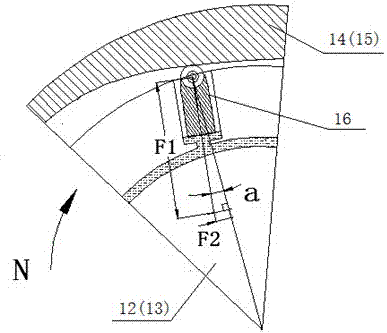

[0028] See figure 1 , the dual clutch body 1 includes an even-numbered clutch I and an odd-numbered clutch II, including a power input shaft 11, two inner rotors 12, 13 connected to the power input shaft 11, and two sleeves on the outer rings of the corresponding inner rotors 12, 13 And the outer rotors 14, 15 connected with the transmission, and the movable teeth 16; the inner peripheral surfaces of the two outer rotors 14, 15 are all variable diameter surfaces, and the variable diameter surfaces are divided into multiple equal parts, each equal The size and direction of the variable diameter of the part are equal; the outer circumferences of the two inner rotors 12, 13 are provided with movable tooth grooves 17, 18, and the bottoms of the movable tooth grooves 17, 18 are respectively connected to the even-numbered high-pressure oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com