Flaw detection inspection slide rail device

A flaw detection, slide rail technology, used in bearings, linear motion bearings, shafts and bearings, etc., can solve problems such as cumbersome operations, affecting work efficiency, and safety hazards, reducing labor, avoiding safety hazards, and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with specific embodiment, further elaborate the present invention.

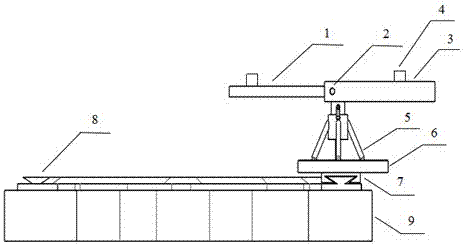

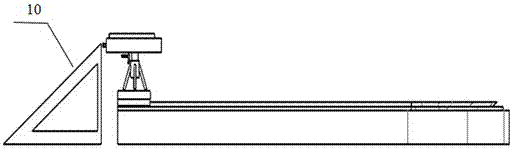

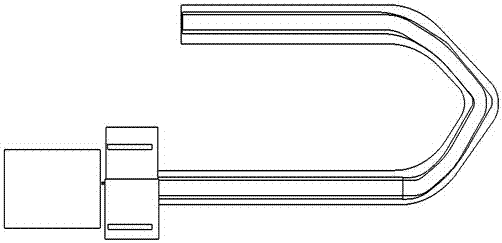

[0014] Such as Figure 1 to Figure 3 As shown, a flaw detection inspection slide rail device, a left support plate 1, a lockable device 2, a right support plate 3, two support bosses 4, a lifting device 5, a support platform 6, a slider 7, and a C-shaped slide rail 8, C-shaped backing plate 9, tank triangle upper and lower frame 10.

[0015] The left support plate 1 is inserted into the right support plate 3 and its position can be fixed by the lockable device 2. Two support bosses 4 are installed above the device to further fix the tank body. Below the platform 6 is that the slide block 7 is connected with the C-shaped slide rail 8 and installed on the C-shaped backing plate 9, and the upper and lower frame 10 of the tank triangle is used in pair with the support plate.

[0016] The left support plate 1 is inserted into the right support plate 3 to fix its position through the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com