Six-freedom-degree series-parallel full-hydraulic tunneling machine

A degree of freedom, full-hydraulic technology, applied in mining equipment, earth-moving mining, tunnels, etc., can solve the problems of lack of decoupling, difficult control, small working space, etc., to achieve simple electronic control operating system, explosion-proof performance and safety. Reliable, overcoming technical flaws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

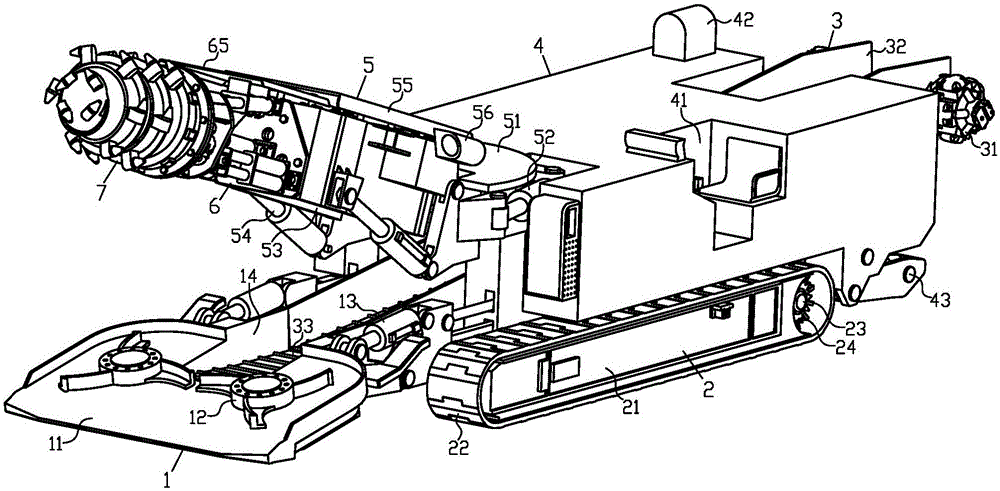

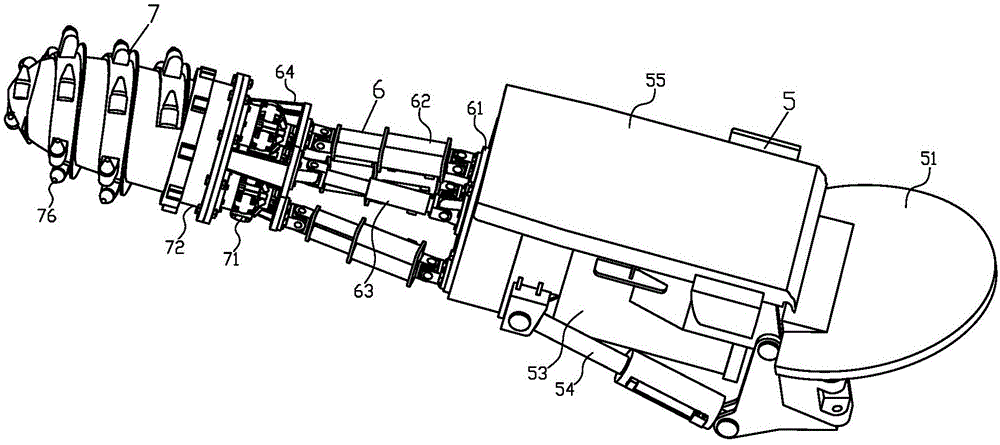

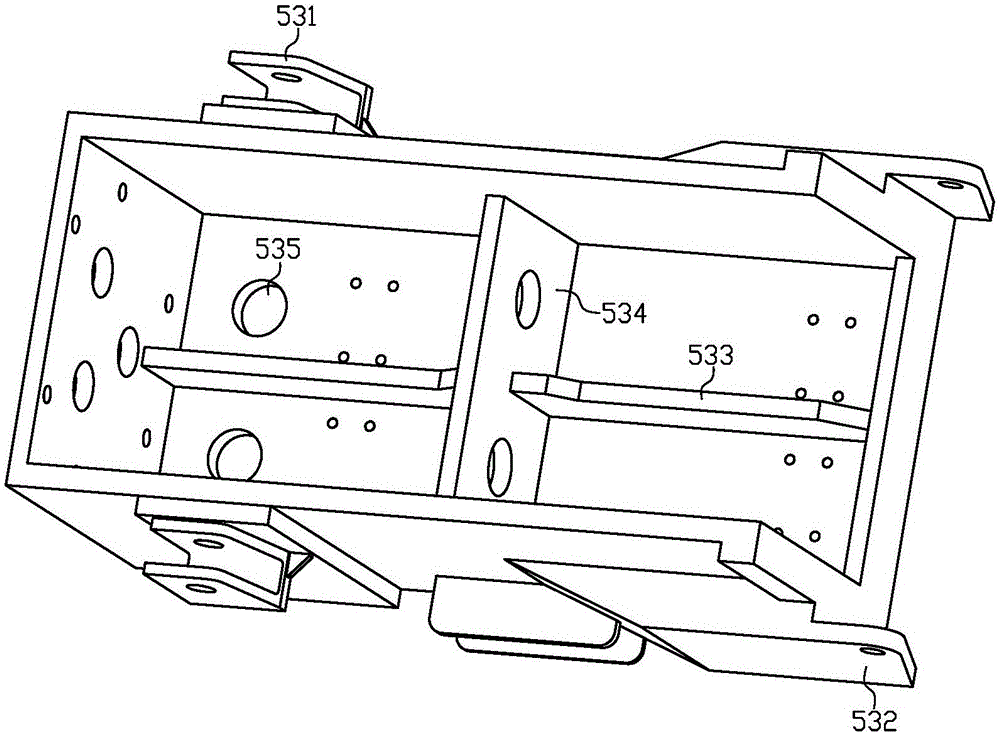

[0032] like figure 1 and figure 2 As shown, a six-degree-of-freedom hybrid full-hydraulic roadheader includes a loading part 1, a walking part 2, a scraper conveyor 3, a fuselage body 4, a two-degree-of-freedom slewing seat 5, a parallel working arm 6 and a cutting head 7 . Among them, the loading part 1 for loading materials such as rocks and coal blocks is located at the front end of the fuselage body 4, and is located below the cutting head 7 and the parallel working arm 6. The loading part 1 includes a shovel 11 and a star wheel 12. 1. Shovel plate lifting cylinder 13 and front chute 14, the star wheel 12 has two groups and is symmetrically installed on the shovel plate 11, and is used to transport the material on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com