Experimental device and method for integrity evaluation of oil and gas well fracturing working condition pitshaft

An experimental method and integrity technology, applied in the direction of wellbore/well components, earthwork drilling, production fluid, etc., can solve the problems of complex failure mechanism of the wellbore and no effective method for evaluating the integrity of the wellbore, and achieve credibility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to have a clearer understanding of the technical features and beneficial effects of the present invention, the technical solutions of the present invention are described in detail below with reference to the accompanying drawings.

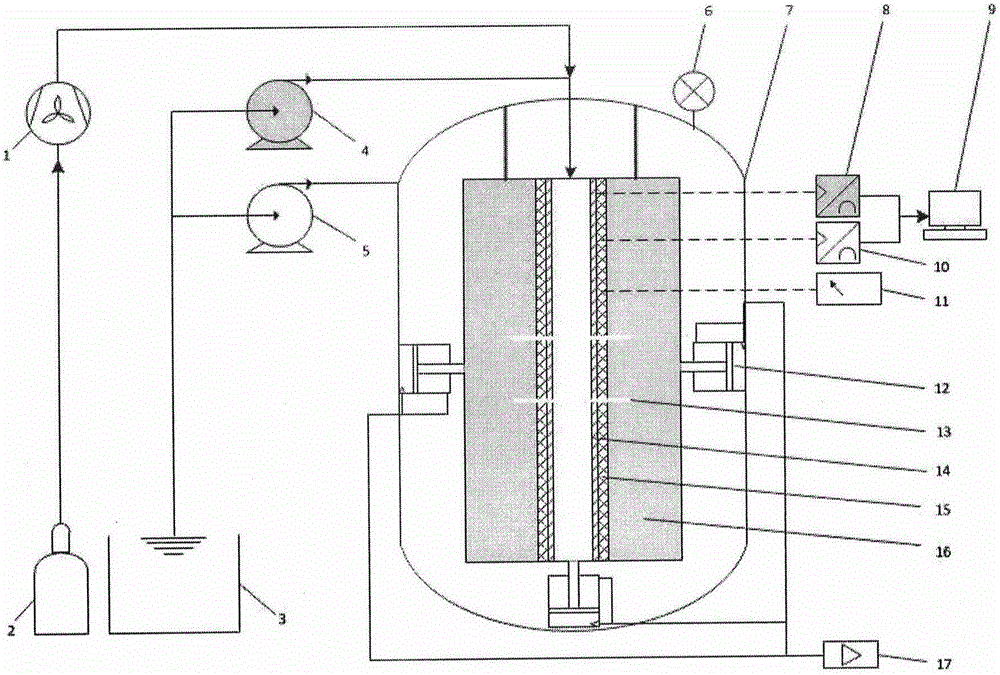

[0010] The invention provides an experimental device for evaluating the integrity of the wellbore in oil and gas well fracturing conditions, as shown in the accompanying drawings. The experimental device for wellbore integrity evaluation under fracturing conditions includes: gas compressor (1), high-pressure gas cylinder (2), water tank (3), internal pressure loading pipeline and high-pressure pump (4), external pressure loading pipeline and high-pressure pump (5), pressure gauge (6), external pressure cylinder liner (7), strain sensor (8), computer (9), air pressure sensor (10), ohmmeter (11), three-way loading hydraulic cylinder (12), Perforation hole (13), casing (14), cement sheath (15), rock mass (16) and hydraulic control modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com