A coiled tubing multi-cluster blasting perforation fluid recovery method and recovery device

A technology of sandblasting perforating and recycling methods, which is applied in separation methods, chemical instruments and methods, and earthwork drilling and mining, etc., can solve the problems of complicated operation, long time consumption, inability to realize the recycling of perforating fluid, etc., and achieve a simple process and process. , the effect of reducing costs and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

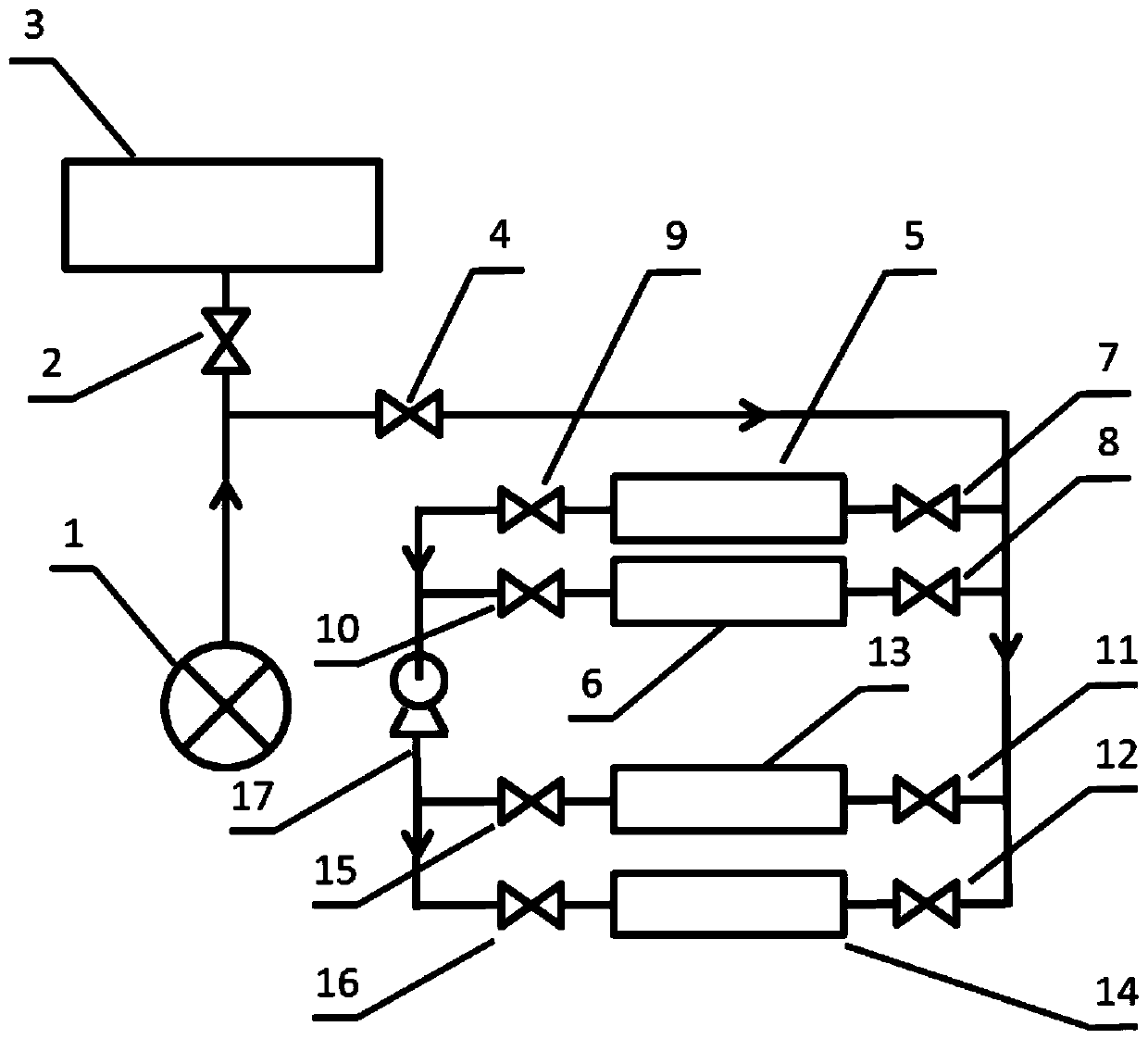

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] Embodiment of a method for recovering liquid from multi-cluster injection holes in coiled tubing of the present invention

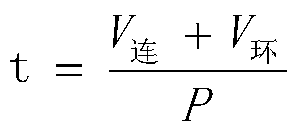

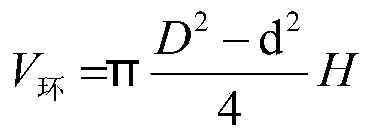

[0029] The coiled tubing multi-cluster injection hole fluid recovery method of the present invention can realize the recovery and utilization of perforating fluid in the coiled tubing bottom seal dragging fracturing reconstruction process of casing cementing and completion horizontal wells, reduce sewage discharge and improve economic benefits . In this method, in the replacement liquid recovery stage, the valve of the replacement liquid recovery tank is opened, and the replacement liquid is recycled into the replacement liquid recovery tank; in the sandblasting liquid recovery stage, the valve of the sandblasting liquid recovery tank is opened, and the The liquid is recovered to the sandblasting liquid recovery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com