A structure and construction method for preventing transmission line cement rods from pulling up

A technology of transmission lines and construction methods, which is applied in the direction of infrastructure engineering, protection devices, building types, etc., can solve the problems of costing funds and engineering quantities, and is difficult to promote on a large scale, so as to achieve small engineering quantities and inhibit the backfilling effect of sand and soil , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

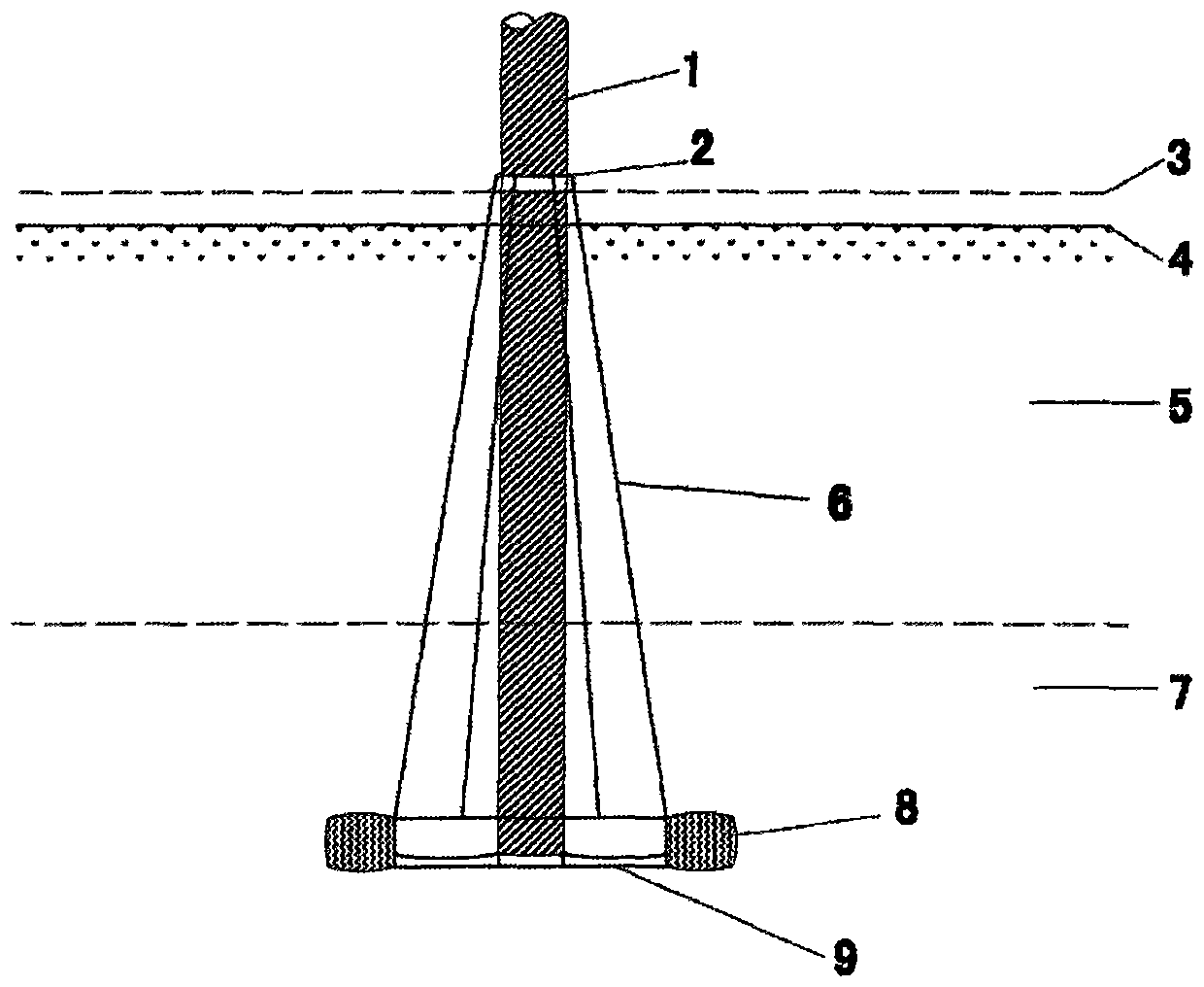

[0029] Embodiment 1: as figure 1 As shown, a structure for preventing the cement rods of transmission lines from pulling up includes cement rods 1, metal rings 2, metal wires 6, waste tires 8 and waste hubs 9. The waste tire 8 and the waste wheel hub 9 are co-installed and placed horizontally, the cement rod 1 is vertically arranged above the waste wheel hub 9, and the steel bar at the bottom of the cement rod 1 is welded to the contact part of the waste wheel hub 9, and a metal ring is set on the top of the cement rod 1 2. Several tensioned metal wires 6 are arranged between the metal ring 2 and the used wheel hub 9, and the several metal wires 6 are evenly distributed. One end of the metal wire 6 is welded to the edge of the waste wheel hub 9, and the other end is welded to the metal ring 2. The metal ring 2 is located above the ground surface. The cement pole 1, waste tires 8 and waste wheel hub 9 below the metal ring 2 are all buried in the The layer of soil below the sur...

Embodiment 2

[0034] Embodiment 2: a kind of construction method that prevents the cement pole of power transmission line from pulling up the structure, it comprises the following steps:

[0035] (1) dig a cement rod pit at the buried cement rod 1 position, and the depth of the cement rod pit is greater than the thickness of the permafrost layer 5;

[0036] (2) The waste tire 8 that is not inflated and the waste wheel hub 9 are installed in cooperation and placed horizontally on the bottom of the cement rod pit;

[0037] (3) set the metal ring 2 on the cement rod 1, and fix the metal ring 2 on the cement rod 1;

[0038] (4) Cement rod 1 is vertically erected in the cement rod pit, and the steel bar at the bottom of the cement rod 1 is welded together with the waste wheel hub 9 contact parts. At this moment, the metal ring 2 is above the horizontal plane;

[0039] (5) one end of several metal wires 6 is fixed on the edge of the waste wheel hub 9 at equal intervals respectively, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com