A kind of uplifting structure and construction method of cement poles for anti-sand soil backfill treatment

A construction method and technology of cement poles, applied in infrastructure engineering, protective devices, buildings, etc., to achieve the effect of increasing uplift resistance, low price, and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

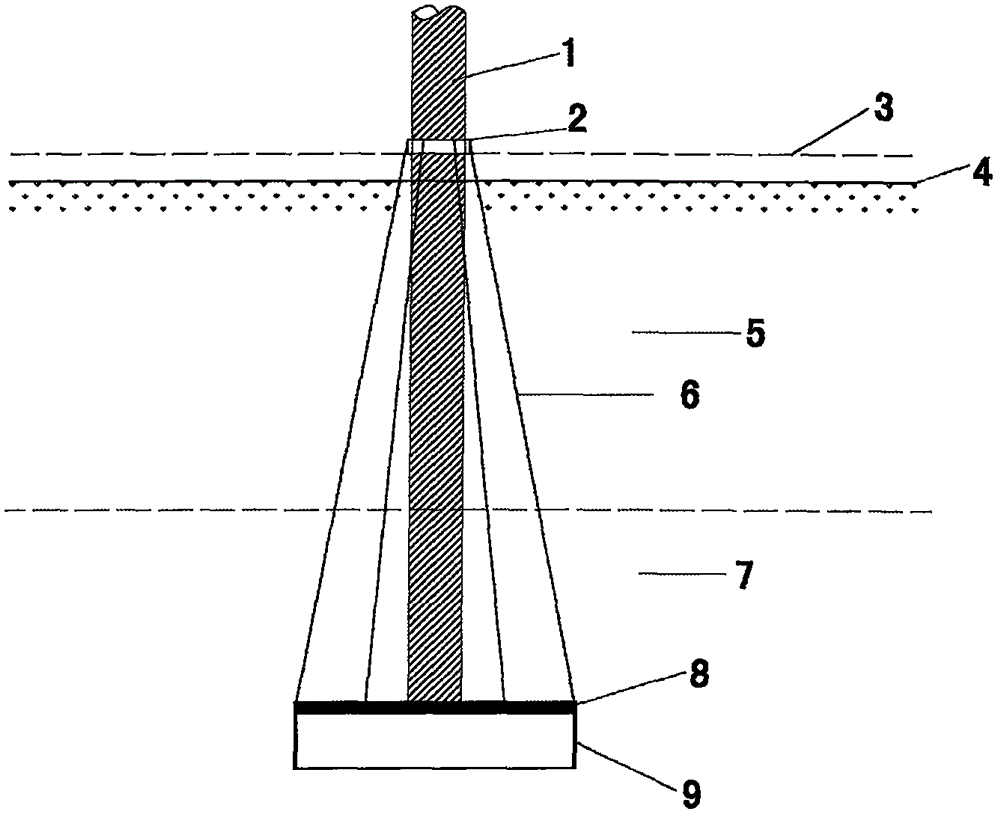

[0033] Embodiment 1: as figure 1 As shown, a kind of anti-sand soil backfill control cement pole pull-up structure, which includes cement pole 1, metal ring 2, metal wire 6, stainless steel plate 8 and annular stainless steel sheet 9, the lower edge of the annular stainless steel sheet 9 is blade-shaped. The bottom of the stainless steel plate 8 is provided with an annular stainless steel sheet 9, the upper edge of the annular stainless steel sheet 9 is welded to the bottom surface of the stainless steel plate 8, the cement rod 1 is vertically arranged above the stainless steel plate 8, and the bottom end of the cement rod 1 is fixed on the stainless steel plate On the top surface of 8, a metal ring 2 is sheathed above the cement rod 1, and several tensioned metal wires 6 are arranged between the metal ring 2 and the stainless steel plate 8, and several metal wires 6 are evenly distributed. One end of the metal wire 6 is welded to the edge of the stainless steel plate 8, and t...

Embodiment 2

[0038] Embodiment 2: Embodiment 1 is a kind of construction method for preventing sand backfilling and controlling the construction of cement rod uplift structure, which includes the following steps:

[0039] (1) dig a cement rod pit at the buried cement rod 1 position, and the depth of the cement rod pit is greater than the thickness of the permafrost layer 5;

[0040] (2) The upper edge of the annular stainless steel sheet 9 is welded to the bottom surface of the stainless steel plate 8 to form a whole;

[0041] (3) The integral body formed by the annular stainless steel sheet 9 and the stainless steel plate 8 is put into the bottom of the cement rod pit, the lower edge of the annular stainless steel sheet 9 is blade-shaped, inserted in the soil at the bottom of the cement rod pit, and the annular stainless steel sheet 9 is vertical Place it so that the stainless steel plate 8 forms a horizontal plane;

[0042] (4) set the metal ring 2 on the cement rod 1, and fix the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com