Cross seam sealing steel cover plate comb tooth telescopic device for bridge and implementation method of cross seam sealing steel cover plate comb tooth telescopic device

A technology for telescopic devices and bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of easy separation, damage and dust accumulation of waterproof rubber, and achieve obvious advantages, improve stress conditions, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

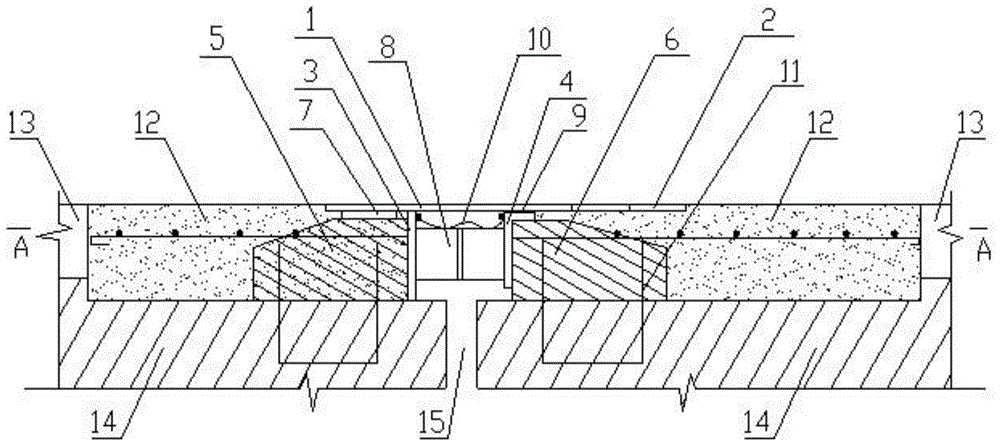

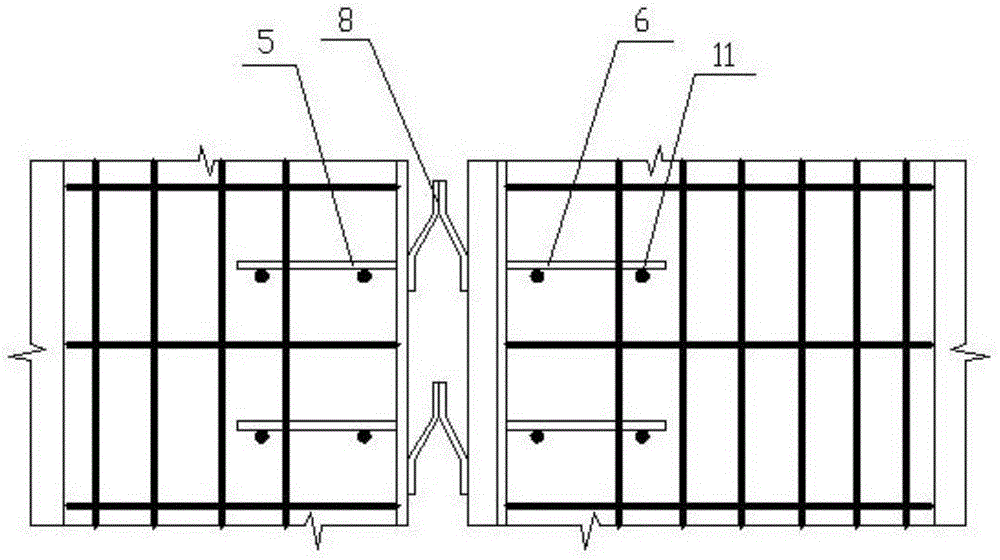

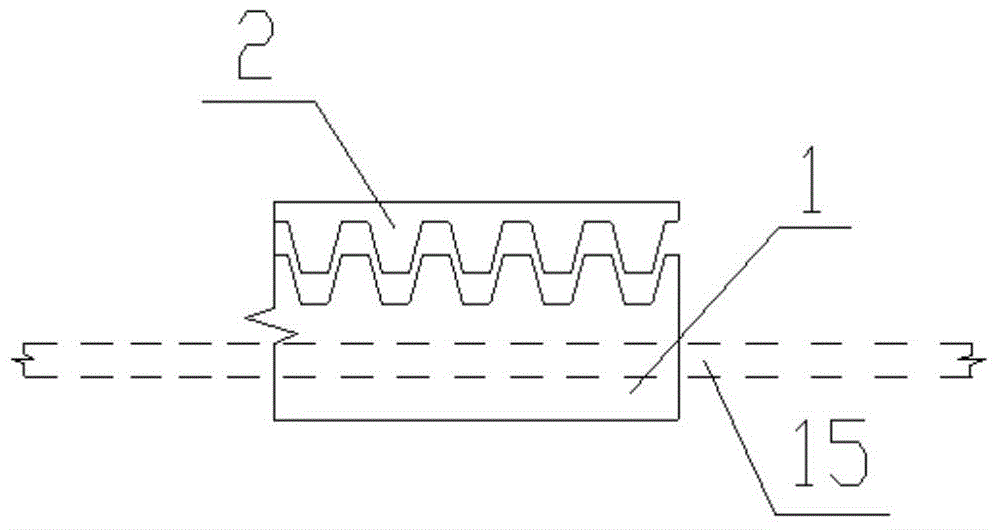

[0025] Combine below Attached picture The present invention is described in detail with examples.

[0026] refer to figure 1 ~ image 3 As shown, the comb-tooth expansion device for bridges of the present invention includes a comb-tooth cover plate 1, a first load-bearing beam 3, a second load-bearing beam 4, and a first positioning anchor plate 5. , the second positioning anchor plate 6, the anchoring spring steel plate 7, the steel elastic body 8, the vulcanized rubber plate 9, the first positioning anchor plate 5 and the second positioning anchor plate 6 are respectively distributed on both sides of the expansion joint 15, the first positioning anchor Plate 5, the second positioning anchor plate 6 are welded and fixed with anchoring reinforcement 11 respectively (the anchoring reinforcement 11 is the steel bar fixed on the concrete on the bridge abutment, belongs to a part of the bridge, and the positioning anchoring plate and its welding play the role of telescopic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com