Fixing assembly for mask plate

A technology for fixing components and masks, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of solid film shape difference, deformation and other problems, to reduce the degree of deformation, easy to manufacture, safe to use reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

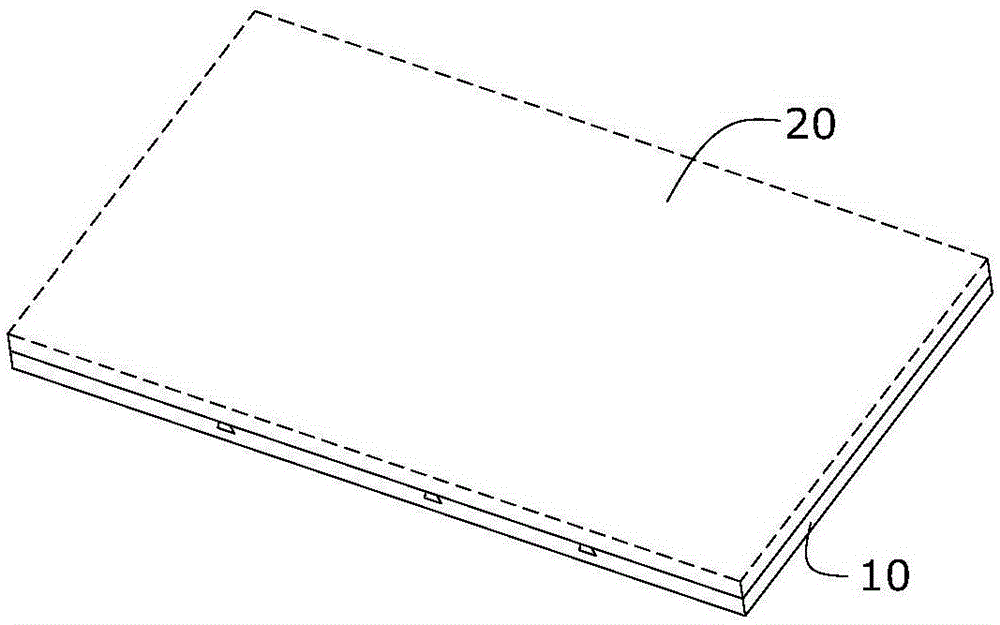

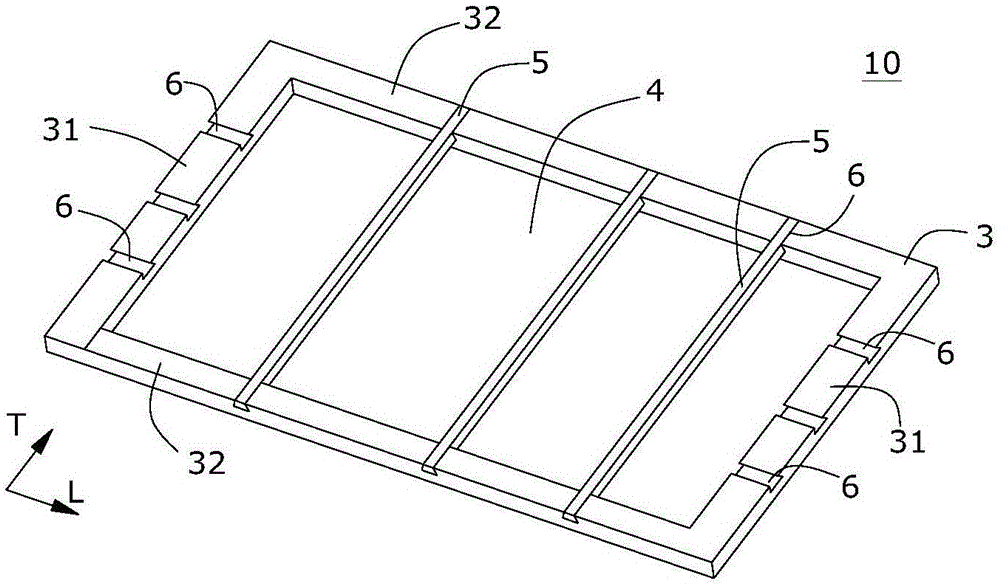

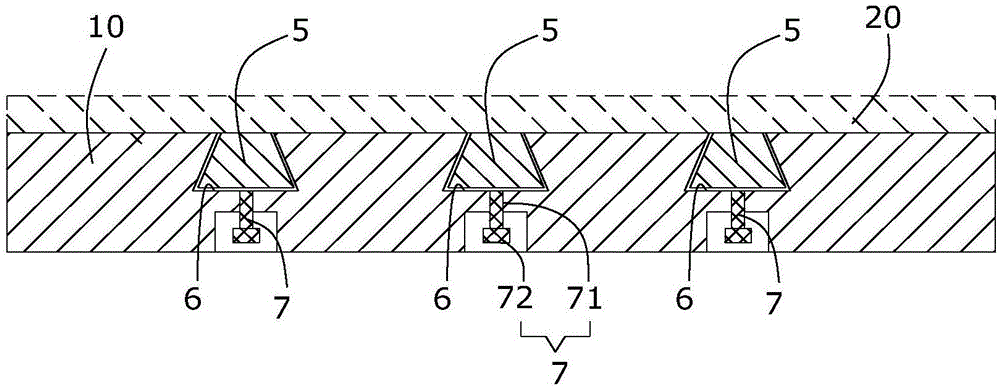

[0025] figure 1 Shows a mask plate fixing assembly 10 and a mask plate 20 according to an embodiment of the present invention, figure 2 A mask plate fixing assembly 10 according to an embodiment of the present invention is shown alone. like figure 1 and figure 2 As shown, the fixture assembly 10 comprises a frame 3 with a hollow vapor deposition area 4 . The frame 3 can be made of stainless steel or nickel-iron alloy material so as to be suitable for harsh conditions during evaporation. The shape of the frame 3 can be a circular frame, a rectangular frame or other polygonal frames. During the manufacturing process, a matching frame 3 is selected according to the shape of the prefabricated display. Normally, the frame 3 is basically the same shape and size as the prefabricated display screen.

[0026] The frame 3 is used to fix the mask plate 20 covering the vapor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com