High-strength wear-resistant polyurethane spectacle frame and preparation method thereof

A spectacle frame and polyurethane technology, applied in the field of spectacle frames, can solve the problems of material thermal aging, skin allergy, poor wear resistance, etc., and achieve the effects of increasing wear resistance, increasing service life and reducing wear rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

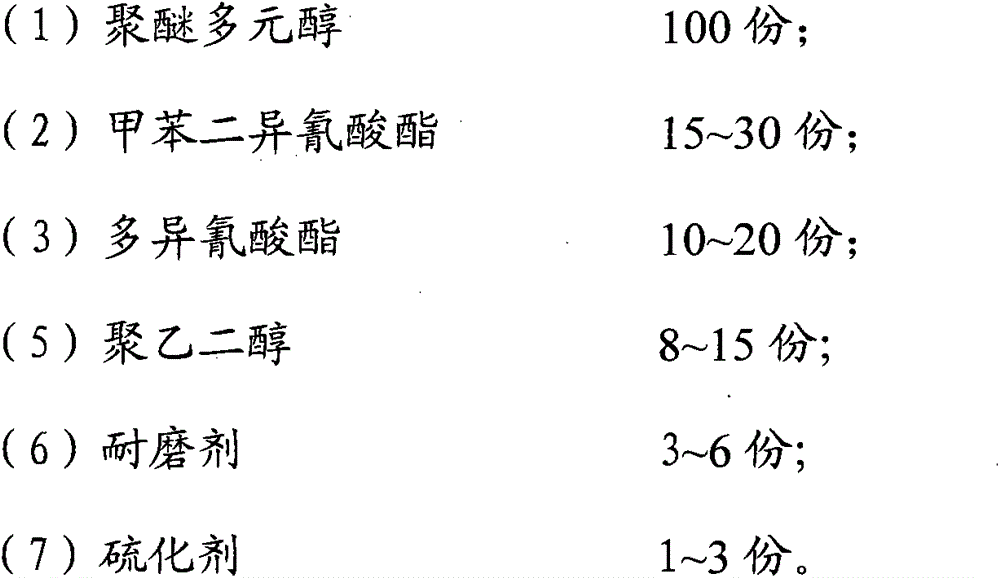

[0013] Adopt the raw material of following weight portion proportioning:

[0014]

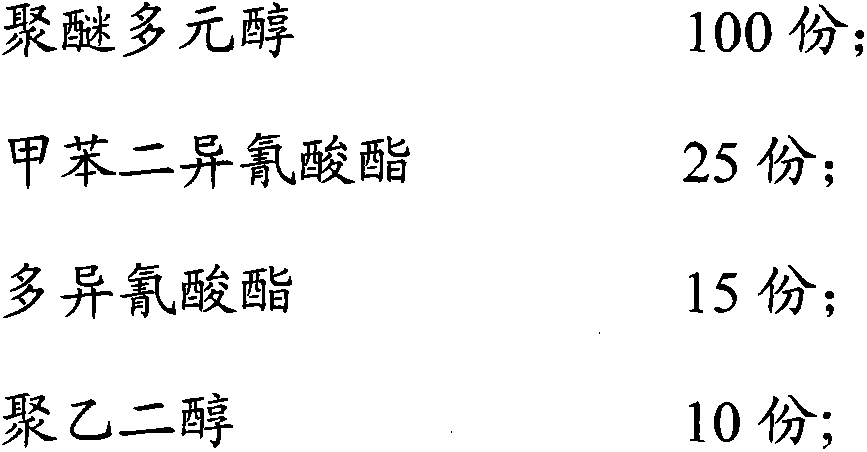

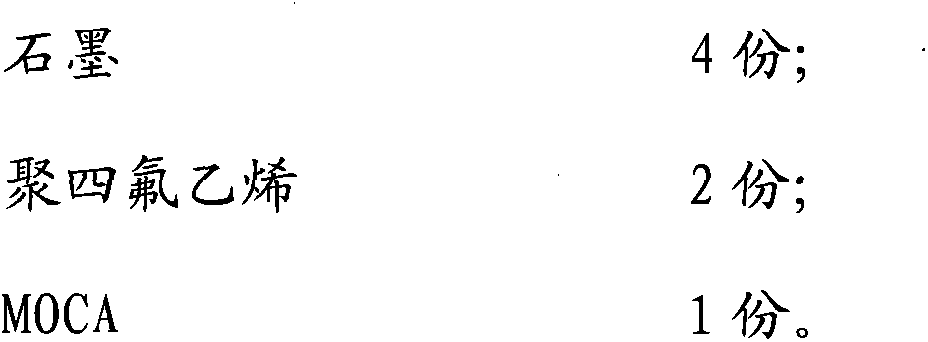

[0015]

[0016] Corresponding preparation process: first add polyether polyol, toluene diisocyanate, polyisocyanate, and polyethylene glycol with the above-mentioned ratio into the reactor, stir at 100°C for 2 hours to fully mix, and then mix the Graphite, polytetrafluoroethylene and MOCA are added to the reactor in turn, stirred at 80°C for 1 hour to fully mix to form injection molding materials, and finally the mixed injection molding materials are quickly poured into the mold of the injection molding machine, and the cooling parts are cooled. The product can be taken out.

Embodiment 2

[0018] Adopt the raw material of following weight portion proportioning:

[0019]

[0020] Corresponding preparation process: first add polyether polyol, toluene diisocyanate, polyisocyanate, and polyethylene glycol with the above-mentioned ratio into the reactor, stir at 105°C for 1.5 hours to fully mix, and then mix the Graphite, polytetrafluoroethylene and MOCA are added to the reactor in turn, stirred at 85°C for 1 hour to fully mix to form injection molding materials, and finally the mixed injection molding materials are quickly poured into the mold of the injection molding machine, and the cooling parts are cooled. The product can be taken out.

Embodiment 3

[0022] Adopt the raw material of following weight portion proportioning:

[0023]

[0024] Corresponding preparation process: first add polyether polyol, toluene diisocyanate, polyisocyanate, and polyethylene glycol with the above-mentioned ratio into the reactor, stir at 110°C for 1.5 hours and mix thoroughly, and then put the Graphite, polytetrafluoroethylene and MOCA are added to the reactor in turn, stirred at 90°C for 1 hour to fully mix to form injection molding materials, and finally the mixed injection molding materials are quickly poured into the mold of the injection molding machine, and the cooling parts are cooled. The product can be taken out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com