Preparation method of europium-bonded fluorescent nano silica microsphere through light curing

A nano-silicon dioxide and silicon dioxide technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of complex preparation process, easy environmental pollution, cumbersome and other problems, and achieve the effect of overcoming the weak physical adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

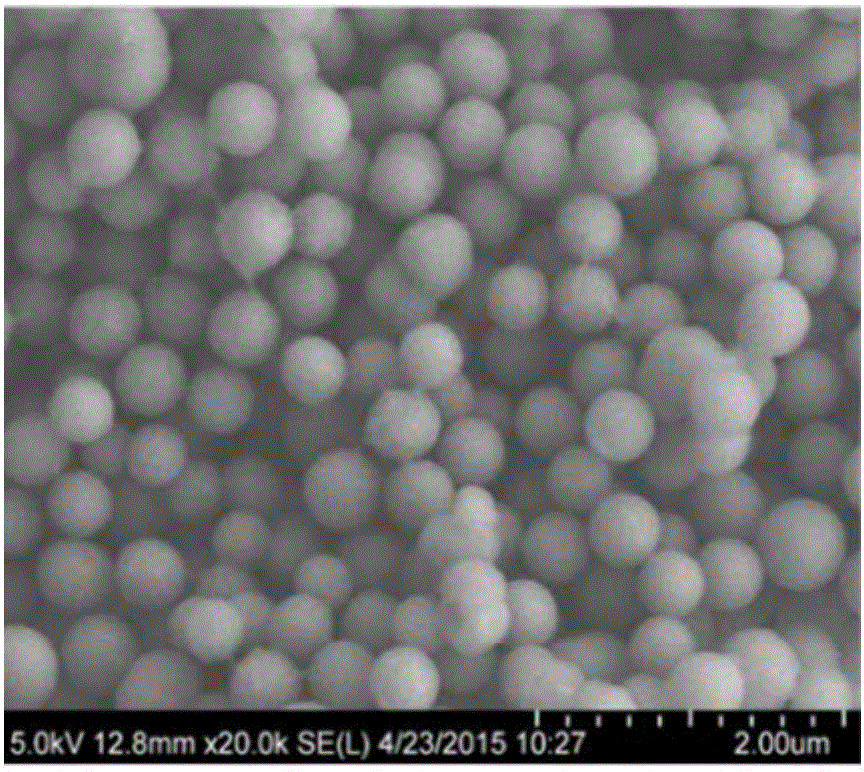

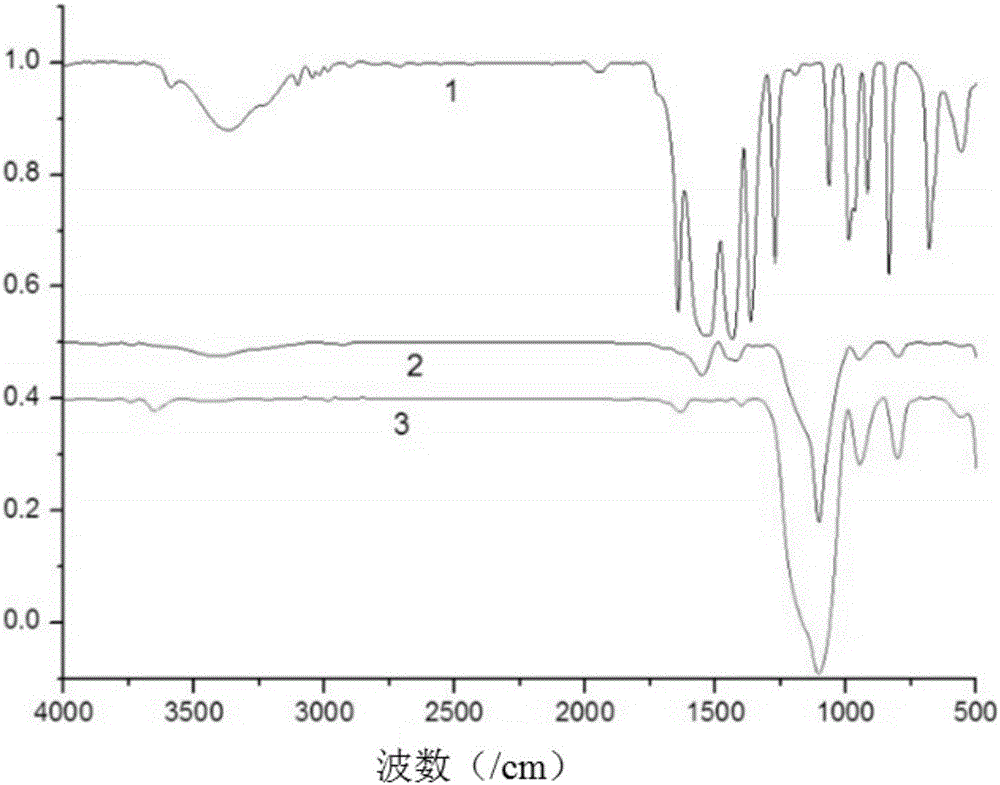

[0025] 1. Preparation of nano-silica microspheres adsorbed on the interface of organosiloxane

[0026] Add 0.2g of nano-silica microspheres (with a particle size of 400-500nm) and 0.1g of 3-propylmethacrylate trimethoxysilane into 30mL of absolute ethanol, ultrasonically disperse for 5 minutes, and place in a constant temperature culture shaker for oscillation Centrifuge for 3 hours (rotating at 200 rpm), and the obtained white precipitate is washed with ethanol and then dried to obtain silica microspheres adsorbed on the interface of 3-propylmethacrylate trimethoxysilane.

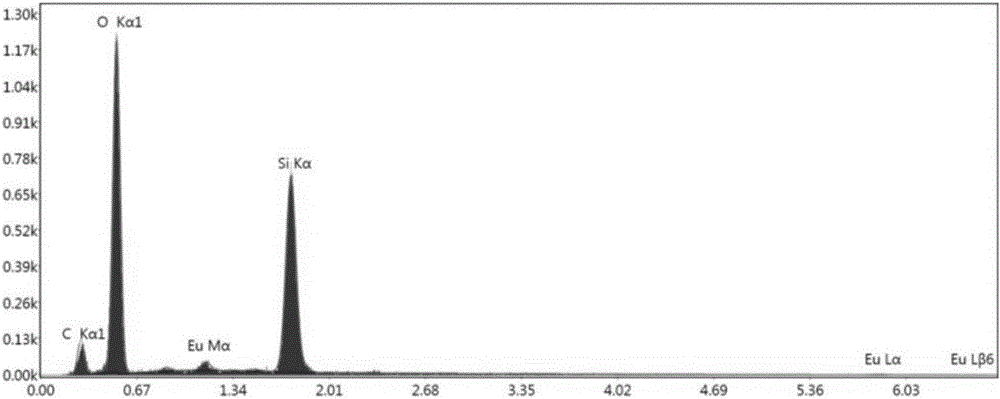

[0027] 2. Preparation of europium-bonded fluorescent nano-silica microspheres by ultraviolet light curing

[0028] Completely dissolve 0.1g of europium acrylate in 0.5mL of dimethyl sulfoxide, add 0.015g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and disperse evenly by ultrasonication, then add the 3-methanol prepared in step 1 Silica microspheres adsorbed on the interface of propyl acrylate trime...

Embodiment 2

[0030] Step 1 of this example is the same as Step 1 of Example 1, preparing silica microspheres adsorbed at the interface of 3-propylmethacrylate trimethoxysilane. In step 2 of this example, dissolve 0.05 g of europium acrylate in 0.5 mL of dimethyl sulfoxide, add 0.015 g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and disperse evenly by ultrasonication, then add The silica microspheres adsorbed on the interface of 3-propyl methacrylate trimethoxysilane prepared in step 1 were stirred evenly, and irradiated with ultraviolet light with a wavelength of 365nm for 10 minutes to obtain europium-bonded fluorescent nano-silica microspheres. ball.

Embodiment 3

[0032] In Examples 1-2, the 3-propyl methacrylate trimethoxysilane used was replaced with an equimolar vinyltrimethoxysilane; 2,4,6-trimethylbenzoyl-diphenyl oxidation The phosphine was replaced by equimolar ethyl 2,4,6-trimethylbenzoylphosphonate, and other steps were the same as in the corresponding examples to obtain europium-bonded fluorescent nano-silica microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com