A kind of down conversion photovoltaic glass and preparation method thereof

A technology of photovoltaic glass and glass layer, applied in the field of down-conversion photovoltaic glass and its preparation, can solve the problems of unsatisfactory light energy loss suppression effect, etc., and achieve the effects of improving photoelectric conversion efficiency, less process flow, and improving light utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

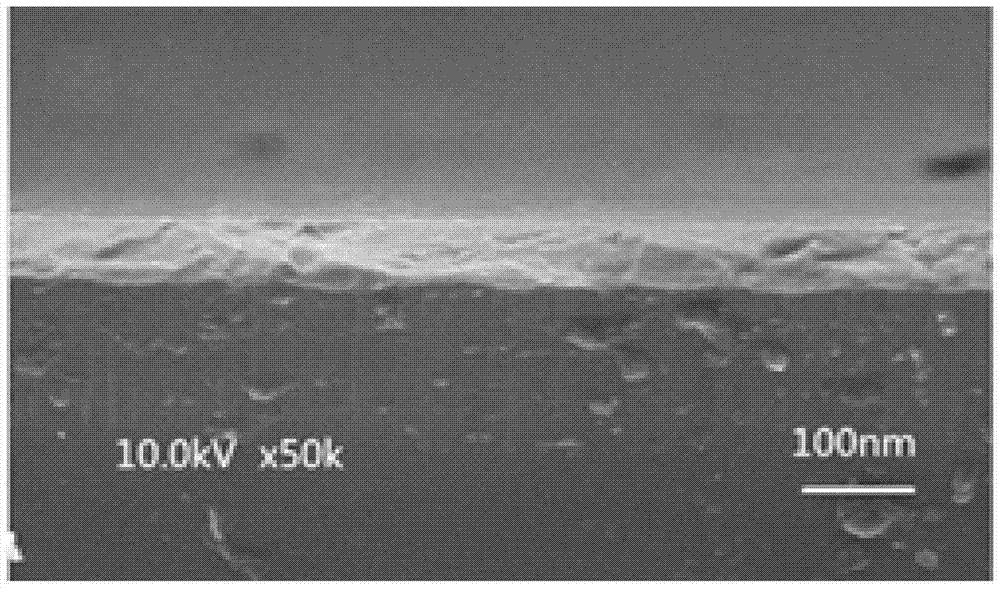

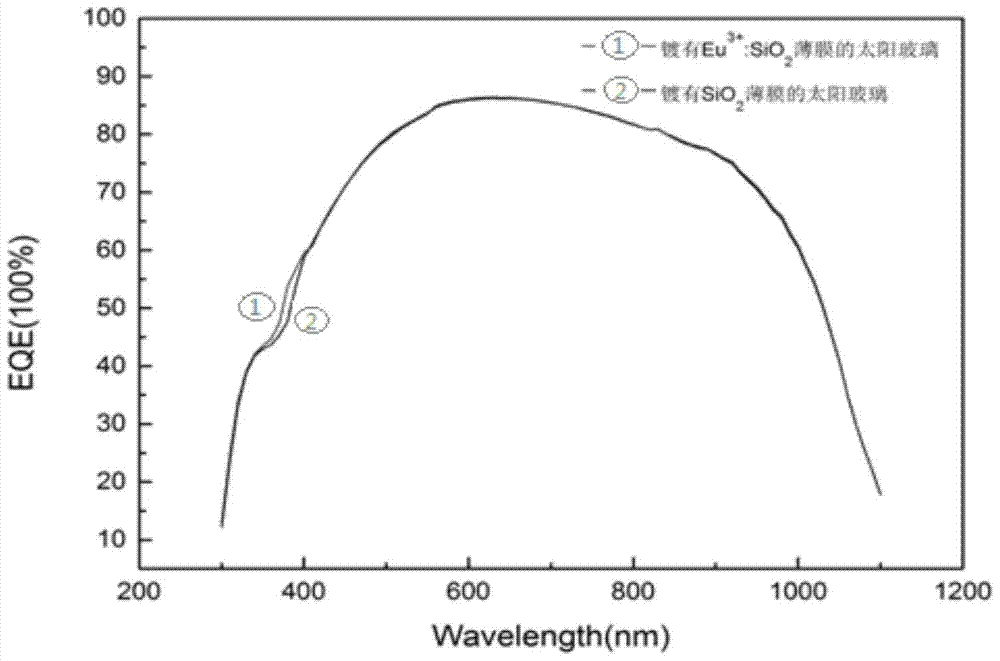

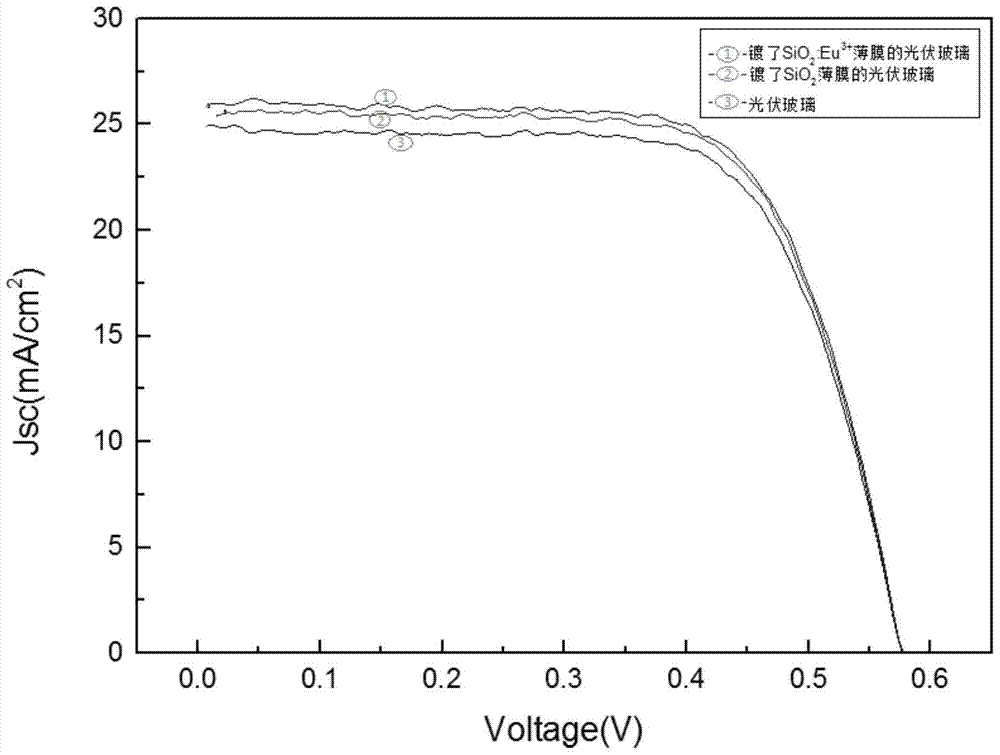

Image

Examples

Embodiment 1

[0027] (1) Preparation of nano-SiO 2 :xEu 3+ ,xNa + Sol, fully aged, the above nano-SiO 2 :xEu 3+ ,xNa + The particle diameter of the sol is 15nm~25nm, the above Na + NaNO 3 Or provided in the form of NaCl solution, specifically:

[0028] a. Ethyl orthosilicate, ethanol, hydrochloric acid and water are measured according to the molar ratio of 1:10~100:0.1~1:1~10, pour all ethyl orthosilicate and half of Mix the ethanol evenly, and stir it magnetically for 30-40 minutes; mix the hydrochloric acid, water and the remaining ethanol, mix evenly, pour it into the above reaction vessel, and stir it magnetically at 30-35°C for 1-1.5 hours;

[0029] b, in the material of step a, add Eu(NO 3 ) 3 、NaCl / NaNO 3 Solution prepared SiO 2 :0.03Eu 3+ ,0.03Na + sol, then stirred at 30°C for 4 hours, and aged for 1 to 3 days to obtain nano-SiO with a particle diameter of 15nm to 25nm. 2 :0.03Eu 3+ ,0.03Na + Sol.

[0030] (2) the above-mentioned nano-SiO 2 :xEu 3+ ,0.03Na + The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com