Special scale inhibitor for saline-alkali soil moistube and preparation method for special scale inhibitor

A technology of scale inhibitor and micro-moisture pipe, which is applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. It can solve the problem of shortened service life of micro-moisture pipe and high salt content in saline-alkali land , low scale inhibition rate and other problems, to achieve the effect of prolonging the service life and reducing the clogging rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

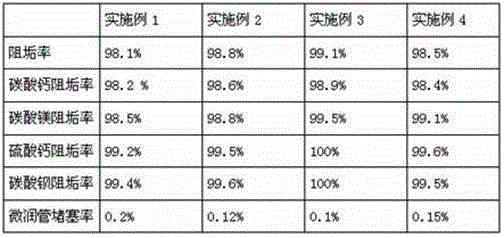

Examples

Embodiment 1

[0024] Example 1 A special antiscalant for micro-moisture pipes in saline-alkali land

[0025] The weight proportion of each component of scale inhibitor is:

[0026] 25 parts of 2-hydroxyphosphinoacetic acid, 27 parts of oxalic acid, 11 parts of citric acid, 9 parts of oxaloacetic acid, 4 parts of sodium lignosulfonate, 9 parts of polyepoxysuccinic acid, 4 parts of propyl hydroxybenzoate, diacetic acid 1.5 parts of sodium, 1 part of allyl polyether, 1 part of dimethyl sulfoxide, 60 parts of water;

[0027] The purity of the oxalic acid: 99%;

[0028] Described citric acid purity: 99%;

[0029] Described water is distilled water.

Embodiment 2

[0030] Embodiment 2 A special antiscalant for micro-moisture pipes in saline-alkali land

[0031] The weight proportion of each component of scale inhibitor is:

[0032] 26 parts of 2-hydroxyphosphinoacetic acid, 28 parts of oxalic acid, 12 parts of citric acid, 10 parts of oxaloacetic acid, 5 parts of sodium lignosulfonate, 9 parts of polyepoxysuccinic acid, 5 parts of propyl hydroxybenzoate, diacetic acid 2.5 parts of sodium, 2 parts of allyl polyether, 1 part of dimethyl sulfoxide, 65 parts of water;

[0033] The purity of the oxalic acid: 99%;

[0034] Described citric acid purity: 99%;

[0035] Described water is distilled water.

Embodiment 3

[0036] Example 3 A special scale inhibitor for micro-wet pipes in saline-alkali land

[0037] The weight proportion of each component of scale inhibitor is:

[0038] 27 parts of 2-hydroxyphosphinoacetic acid, 29 parts of oxalic acid, 12 parts of citric acid, 11 parts of oxaloacetic acid, 7 parts of sodium lignosulfonate, 10 parts of polyepoxysuccinic acid, 4 parts of propyl hydroxybenzoate, diacetic acid 3 parts of sodium, 2 parts of allyl polyether, 2 parts of dimethyl sulfoxide, 68 parts of water;

[0039] The purity of the oxalic acid: 99%;

[0040] Described citric acid purity: 99%;

[0041] Described water is distilled water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com