Preparation method for reinforced graphene surfactant

A graphene surface and active agent technology, which is applied in the field of graphene surfactant preparation, can solve the problems of poor compatibility between graphene oxide and organic solvents, and achieve low cost, short production cycle and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

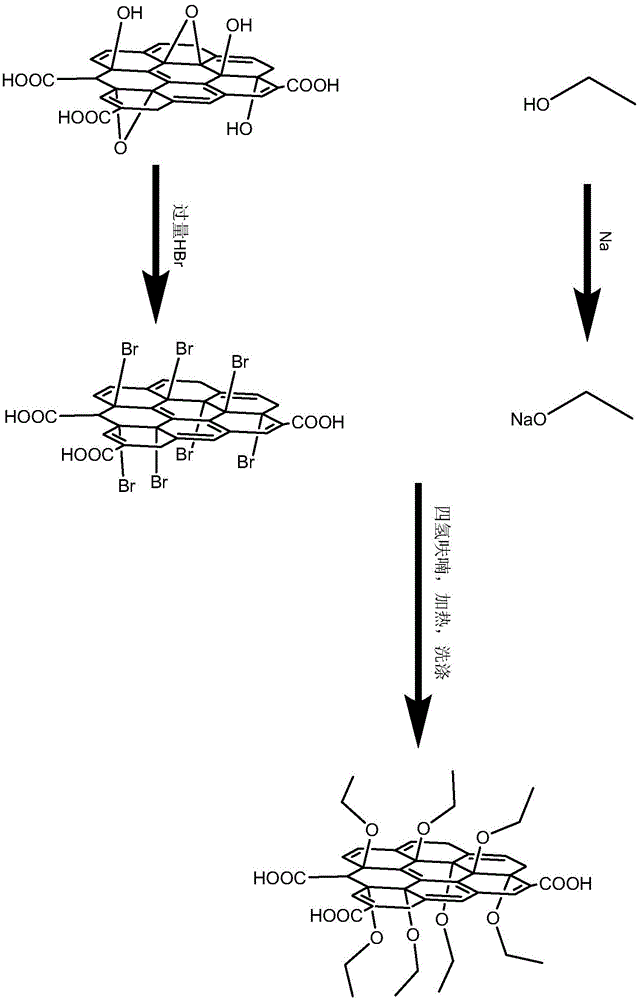

[0024] Specific embodiment one: the preparation method of a kind of enhanced graphene surfactant of the present embodiment is carried out according to the following steps:

[0025] 1. Preparation of graphene oxide: Add 23mL of concentrated sulfuric acid with a mass concentration of 98% to a 250mL large beaker, ice-bath, then add 1g of natural graphite, and stir for 10-40min at a speed of 300-400r / min , add 6 g of KMnO in 6 times on average at a temperature of 0-5 °C 4 , then stirred at a speed of 300-400r / min for 2-2.5h, replaced the ice bath, placed in a constant temperature water bath at 30-40°C, stirred at a speed of 300-400r / min for 30-60min, and the solution became viscous. Finally, the water temperature is stabilized at 40-50°C, and then transferred to an 80°C constant temperature water bath for stirring at 300-400r / min. After ~20min, add 60mL of distilled water to dilute, add 10.81mL of 30% hydrogen peroxide and 60mL of distilled water to form a mixed solution, after u...

specific Embodiment approach 2

[0037] Embodiment 2: The difference between this embodiment and Embodiment 1 is that 1 g of natural graphite is added in Step 1, and the mixture is stirred for 30 minutes at a rotation speed of 400 r / min. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0038] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 1, place in a constant temperature water bath at 30° C. and stir at 300 r / min for 40 min. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com