MEMS technology preparation method of piezoelectret matrix

A piezoelectric electret and matrix technology, which is applied in the process of producing decorative surface effects, metal material coating process, decorative art, etc., can solve the problem of low preparation efficiency and achieve the effect of free and flexible regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0029] The preparation method of the MEMS process of the piezoelectric electret substrate of the present embodiment, comprises the following steps:

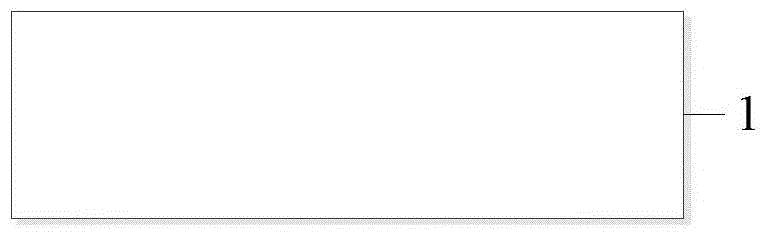

[0030] 1) Provide the substrate 1, the material is Si, and the thickness is 400 μm, such as figure 1 shown;

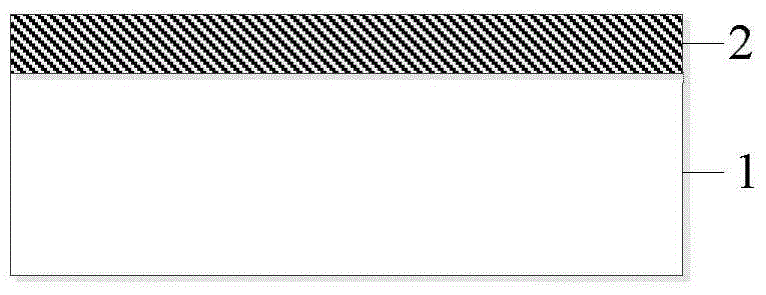

[0031] 2) Spin-coat photoresist 2 on the substrate. The photoresist is AZP4620 with a thickness of 7 μm. Use a hot oven to soft-bake the photoresist at a temperature of 150 ° C for 25 minutes. figure 2 shown;

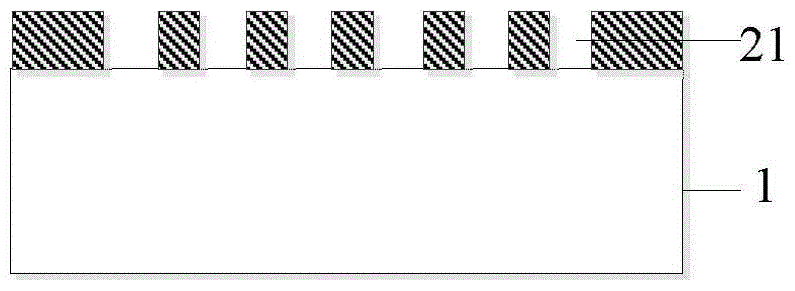

[0032] 3) According to the pattern of the holes of the required piezoelectric electret substrate designed on the first photoresist plate, the pattern of the first photoresist plate is transferred to the photoresist by ultraviolet exposure, the exposure time is 9 seconds, and the development time is 1.5 seconds. Minutes, just can form the figure 21 of required hole on photoresist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com