Sand core lifting device

A lifting device, sand core technology, applied in the directions of transportation and packaging, cores, load hanging components, etc., can solve the problems of casting inclusions, affecting the surface quality of castings, affecting the surface quality of sand cores or mud cores, etc. Surface quality, avoid the effect of poor surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical solution of the present invention more clearly expressed, the present invention will be further described below in conjunction with the accompanying drawings.

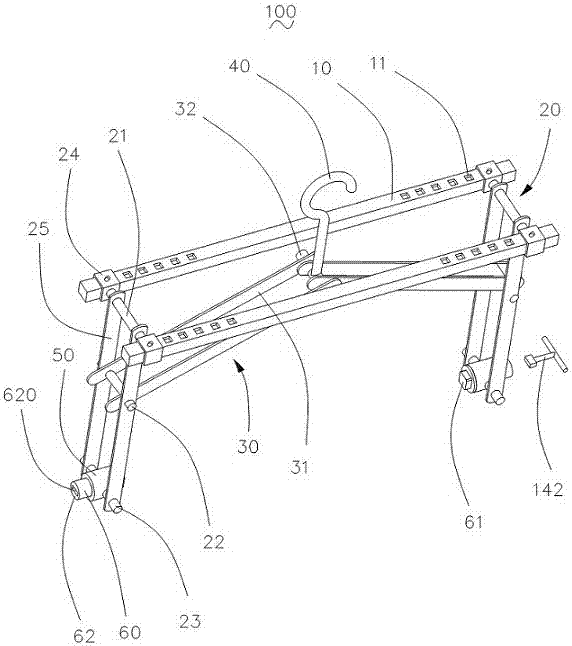

[0015] Please refer to figure 1 , a sand core lifting device 100 according to a preferred embodiment of the present invention is used for clamping and lifting sand cores or mud cores. The sand core lifting device 100 includes two crossbeams 10, two straight tie bars 20, two oblique tie bars 30, a hook 40, two rotor seats 50, two rotors 60 and the rotor 60 supporting The angle adjuster 142. The crossbeams 10 are arranged at intervals, the straight-stay groups 20 are respectively connected to the two ends of the cross-beams 10, one end of each oblique-stay group 30 is pivotally connected to the corresponding straight-stay group 20, and the other end is connected to the suspension. The hooks 40 are connected; the rotor base 50 is connected with the corresponding straight rib group 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com