Multi-station automatic center surface coiler

A fully automatic, multi-station technology, applied in the field of coilers, can solve the problems of ingenious structural design, deformed coiled products, poor tension control, etc., achieve ingenious structural design, maintain constant pressure, and enhance the effect of removing bubbles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

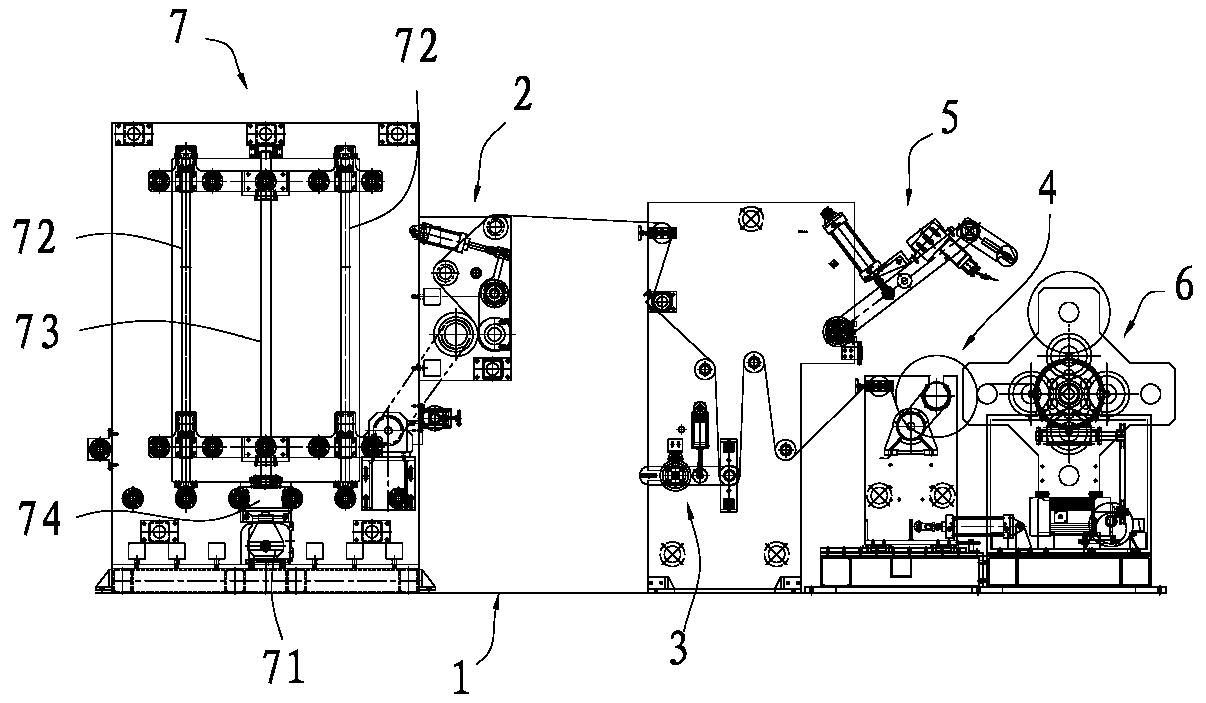

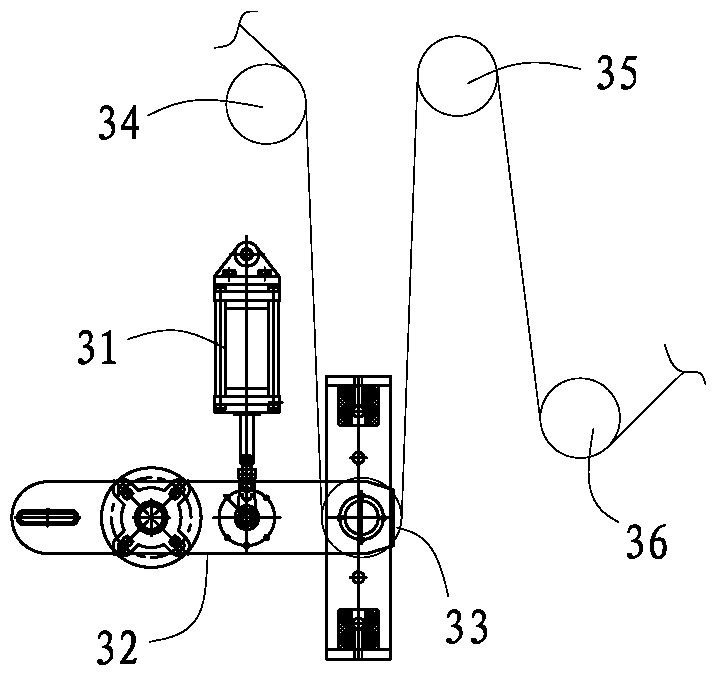

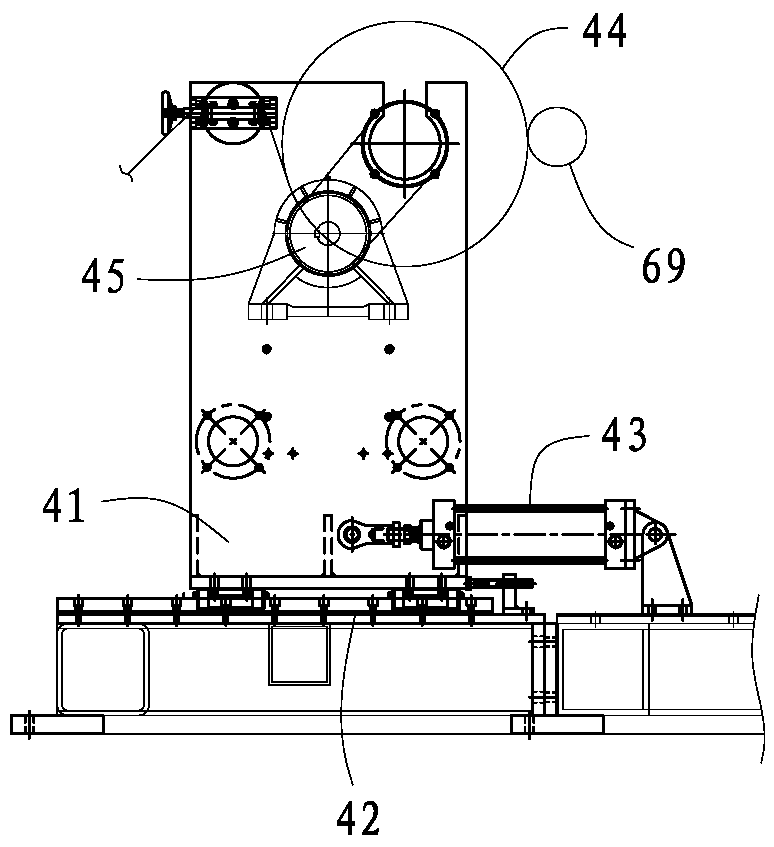

[0018] see Figure 1 to Figure 5 , a kind of multi-station full-automatic center surface coiling machine that the present embodiment provides, and it comprises frame 1, pulley group 2, floating roller group 3, pressure roller group 4, cut film cutter mechanism 5 and be equipped with at least three The coiling and turning mechanism 6 of a winding station 61, the traction wheel group 2, the floating roller group 3, the pinch wheel group 4 and the winding and turning mechanism 6 are successively arranged on the frame 1 according to the order of arrangement, The film cutting knife mechanism 5 is arranged on the frame 1 corresponding to the position between the pressing wheel group 4 and the coiling turning mechanism 6, and can cut off the film material when it goes down.

[0019] Specifically, see Figure 4 , the film cutting knife mechanism 5 includes a cutting arm 51, a pressure knife cylinder 52, a film breaking pressure wheel 54 and a blade 53, one end of the cutting arm 51 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com