Intelligent and automatic spinning cake doffing and conveying device

An automatic doffing and conveying device technology, applied in the field of chemical fiber intelligence, can solve the problems of polluting the chemical fiber cake, increasing labor costs, affecting product quality, etc., and achieving the effect of improving transmission efficiency, reducing accuracy, and uniform bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

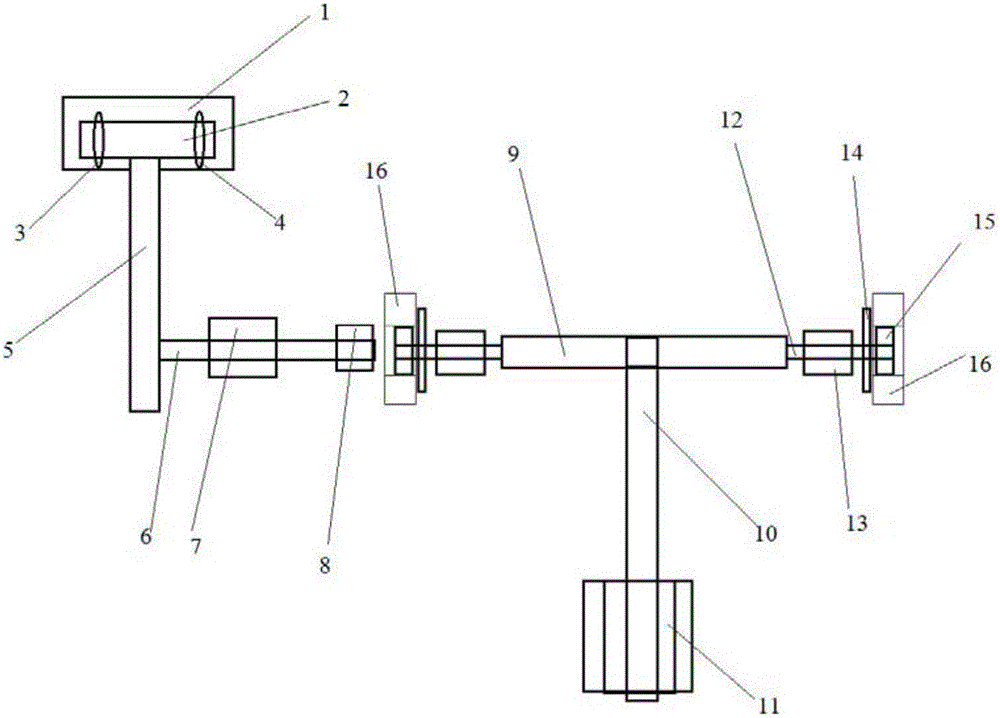

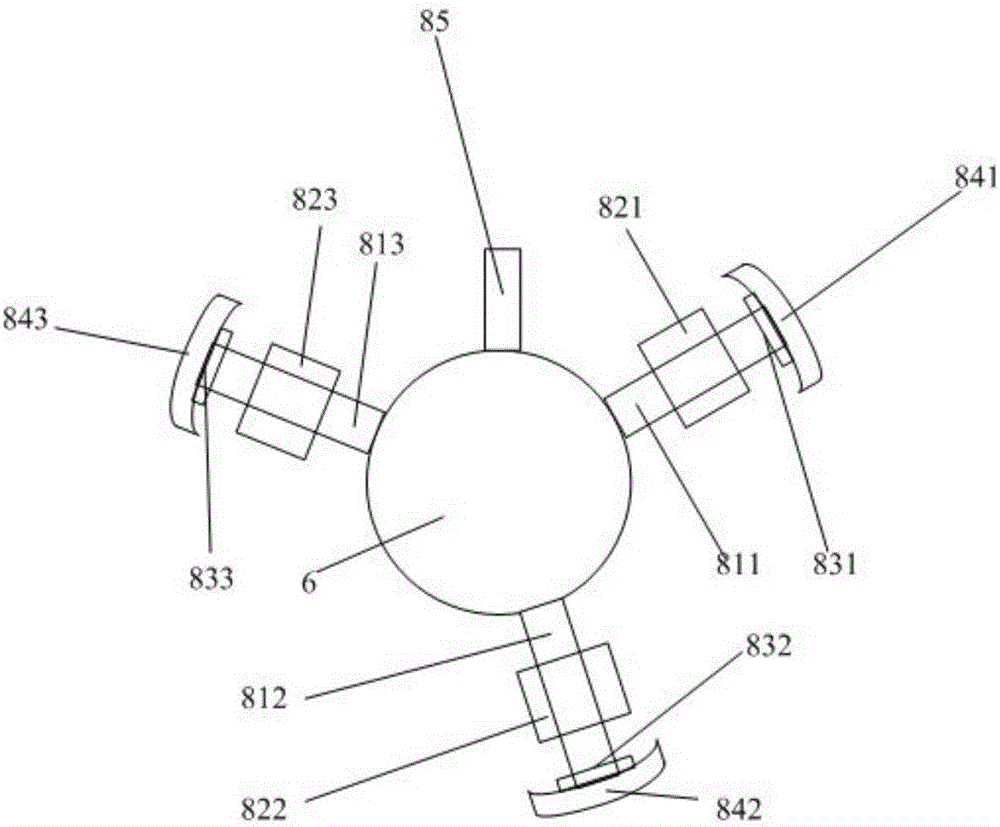

[0031] Please see attached figure 1 , 2, 3, an intelligent automatic doffing and transmission device for silk cakes, which includes a transmission system and a transmission system in two parts, wherein,

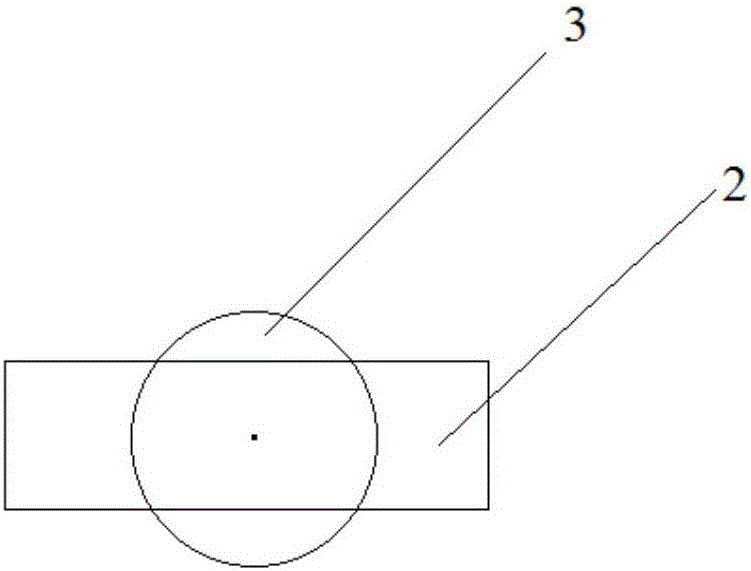

[0032] The transmission system includes a transmission beam 1, a transmission support plate 2, a first transmission rotating wheel 3, a second transmission rotating wheel 4, a transmission rod pillar 5, a transmission rod beam 6, a transmission rod retractor 7, and a transmission rod fixed printing system 8;

[0033] The top of the transmission beam 1 is fixed on the top of the factory building by screws to form a fixed guide rail; the transmission support plate 2 and the transmission rod pillar 5 form a "T" shape; the first transmission rotating wheel 3 and the second transmission rotating wheel 4 are inlaid on the transmission support plate 2 both ends; the upper end of the transmission rod pillar 5 is fixed to the transmission support plate 2 by screws, one end of the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com