Integral molding method of earphone case and integrally formed earphone case

A molding method and the technology of earphone sets, which are applied in the direction of earpiece/earphone accessories, etc., can solve the problems that the earphone sets cannot realize the automatic production of equipment, affect the overall benefit and living environment of the enterprise, and the output of voltage process is low, so as to improve the brand reputation, The effect of improving the level of green environmental protection, improving product reliability and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

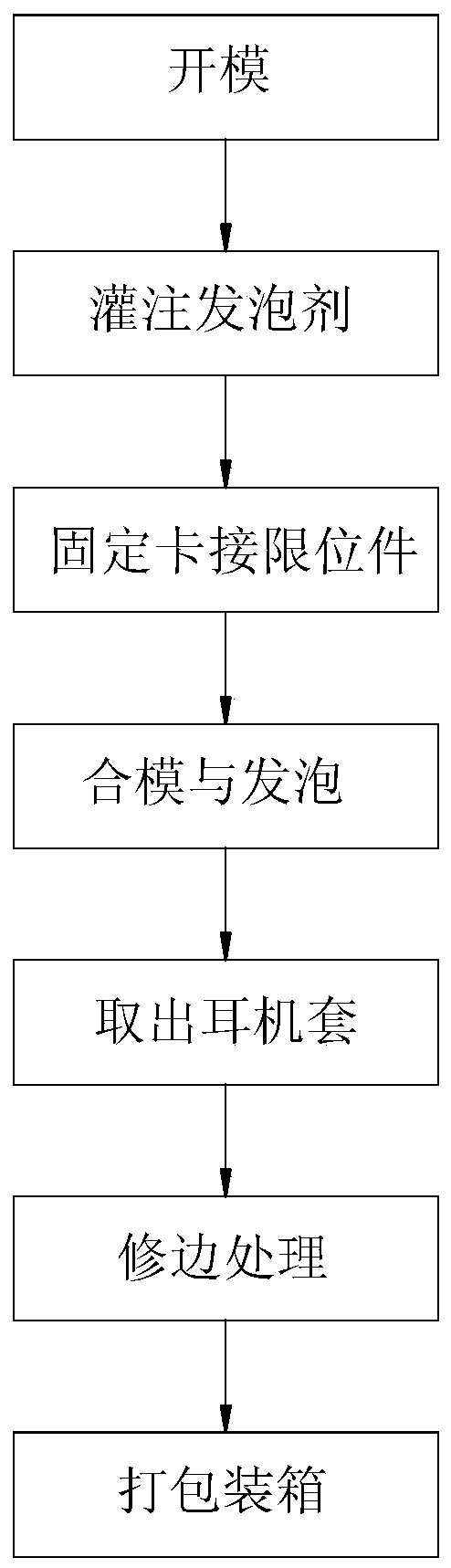

[0069] Such as figure 1 , Figure 5 and Figure 6 As shown, on the one hand, there is provided an integrated molding method for earphone covers, comprising the following steps:

[0070] Provide molds;

[0071] Provide a foaming agent, and pour the foaming agent into the cavity 31 of the mould;

[0072] Provide a snap-in limiter 2, fix the snap-in limiter 2 at the opening position of the mold cavity 31, and place the foaming agent in the cavity 31 and the snap-in limiter 2 inside the enclosed cavity;

[0073] Clamping and foaming;

[0074] Demoulding and taking out the earphone cover from the cavity 31 of the mould;

[0075] De-edge and edge-trimming are performed on the earphone cover;

[0076] quality inspection;

[0077] Pack the box.

[0078] Specifically, the foaming agent and the clamping limiting member 2 are placed together in the mold, and the foaming agent is combined with the clamping limiting member 2 in the process of foaming and forming The integrated st...

Embodiment 2

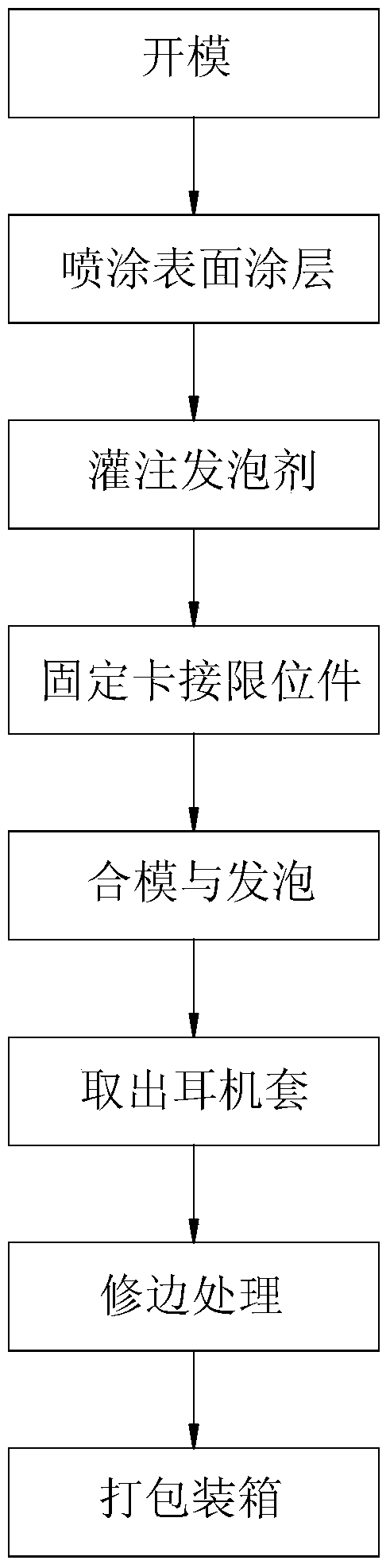

[0085] Such as figure 2 As shown, on the one hand, there is provided an integrated molding method for earphone covers, comprising the following steps:

[0086] Provide molds;

[0087] providing a foaming agent, pouring the foaming agent into the cavity of the mould;

[0088] Provide a snap-in limiter, fix the snap-in limiter at the opening position of the mold cavity, place the foaming agent in the cavity surrounded by the cavity and the snap-in limiter cavity;

[0089] Clamping and foaming;

[0090] Demoulding and taking out the earphone cover from the cavity of the mould;

[0091] De-edge and edge-trimming are performed on the earphone cover;

[0092] quality inspection;

[0093] Pack the box.

[0094] In this embodiment, the mold includes an upper mold and a lower mold that are oppositely arranged, the upper mold and the lower mold selectively abut to form a closed cavity, and the lower mold is provided with the mold cavity. The opening position of the mold cavity ...

Embodiment 3

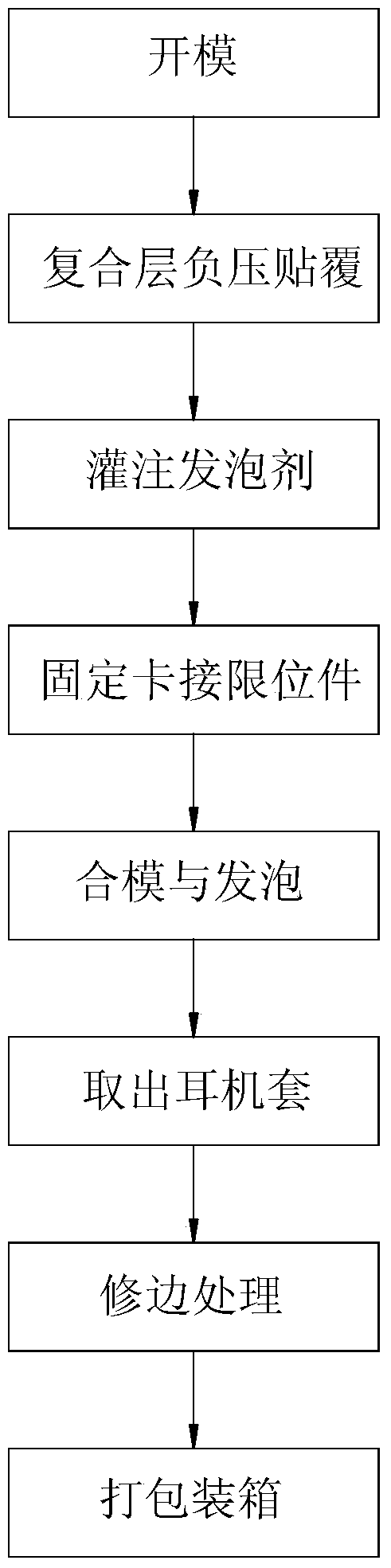

[0104] Such as image 3 As shown, on the one hand, there is provided an integrated molding method for earphone covers, comprising the following steps:

[0105] Provide molds;

[0106] providing a foaming agent, pouring the foaming agent into the cavity of the mould;

[0107] Provide a snap-in limiter, fix the snap-in limiter at the opening position of the mold cavity, place the foaming agent in the cavity surrounded by the cavity and the snap-in limiter cavity;

[0108] Clamping and foaming;

[0109] Demoulding and taking out the earphone cover from the cavity of the mould;

[0110] De-edge and edge-trimming are performed on the earphone cover;

[0111] quality inspection;

[0112] Pack the box.

[0113] In this embodiment, the mold includes an upper mold and a lower mold that are oppositely arranged, the upper mold and the lower mold selectively abut to form a closed cavity, and the lower mold is provided with the mold cavity. The opening position of the mold cavity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com