Deformation resistant welding clamp for pipeline assembly and method for preventing pipeline assembly from deformation by utilizing clamp

A welding fixture and anti-deformation technology, applied in the field of thermal processing of pipe fittings, can solve the problems of no effective preventive measures for pipe deformation, baking marks, and difficult to correct pipes, so as to avoid material and surface damage of pipe fittings and meet the scale of enterprises. The effect of production, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

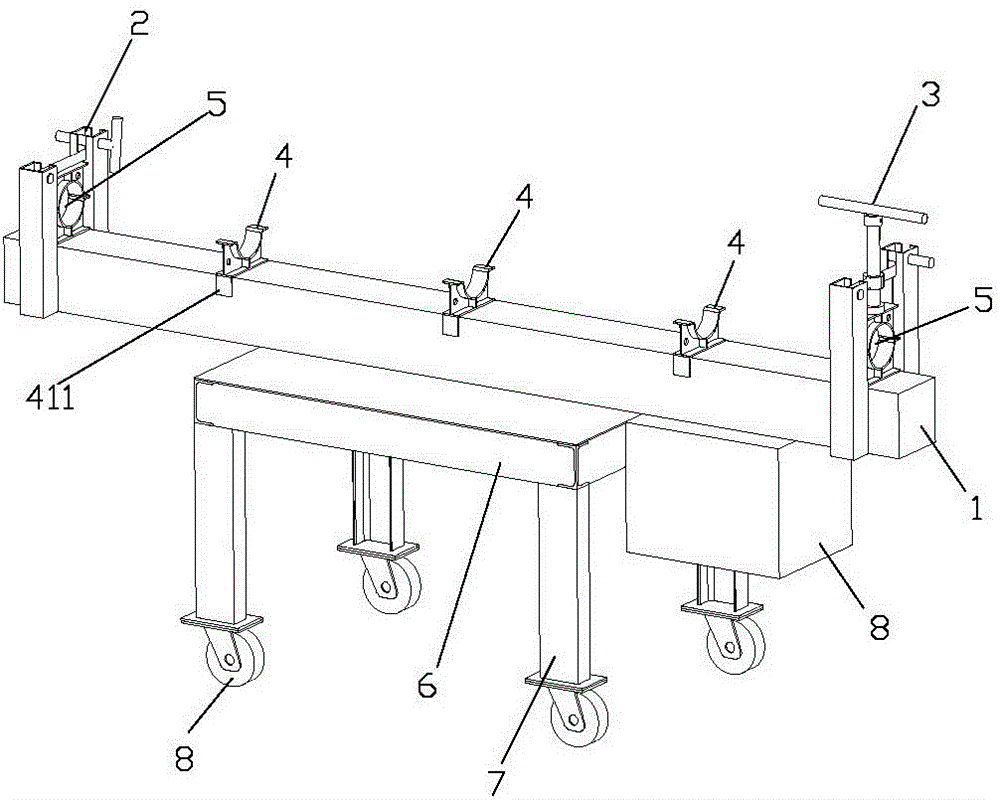

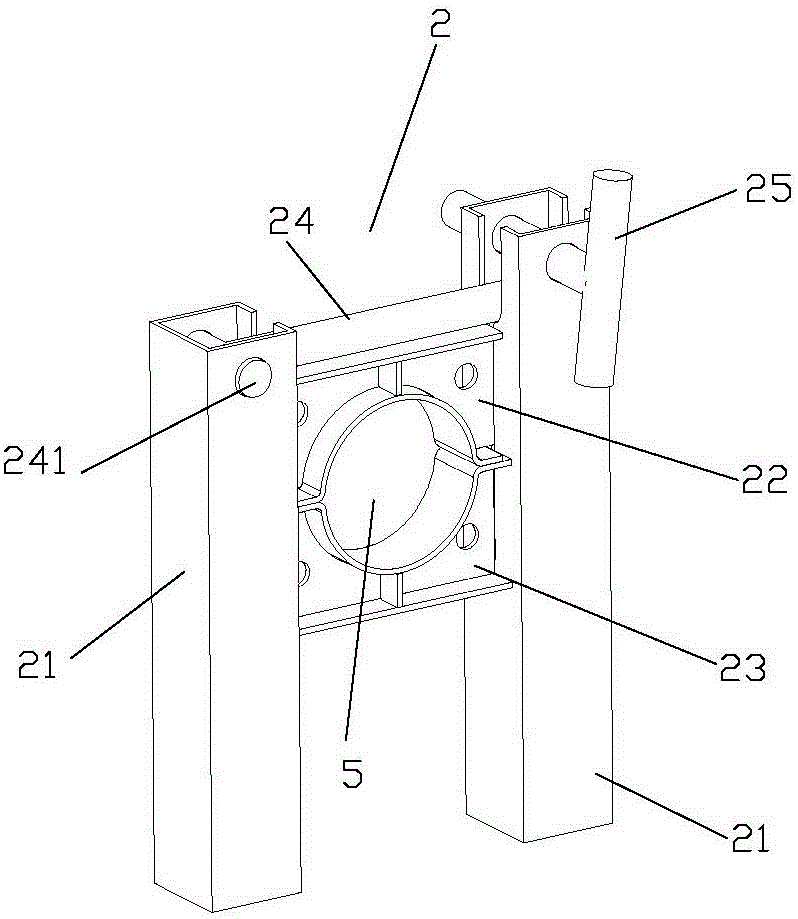

[0058] A pipe fitting anti-deformation welding fixture, such as Figure 1 to Figure 6 As shown, it includes a support 1 , a fixing device 2 arranged at one end of the support 1 for clamping and fixing the pipe, and an adjusting device 3 arranged at the other end of the support 1 for adjusting the clamped position of the pipe.

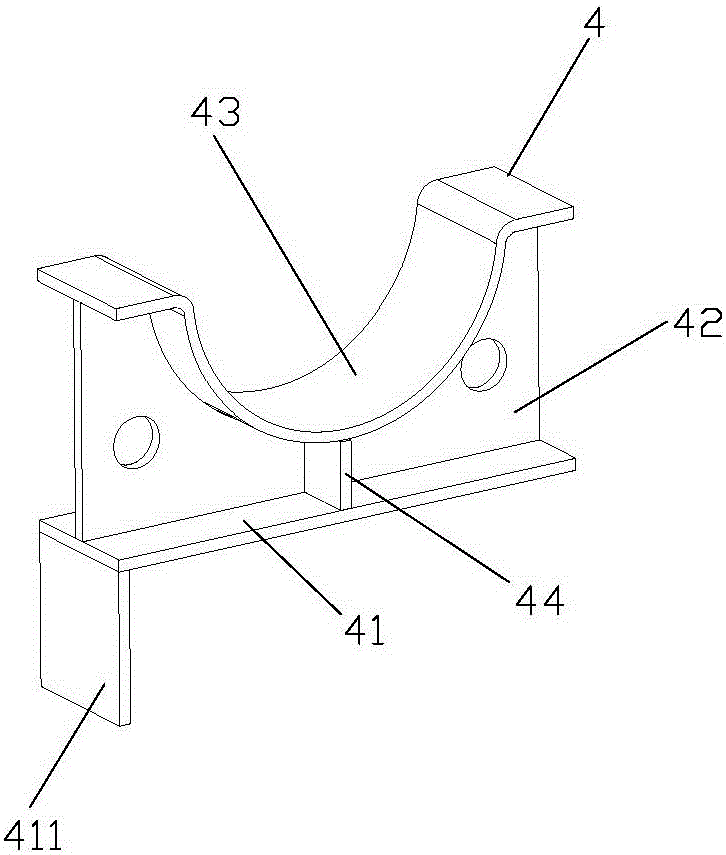

[0059] The support 1 is provided with several anti-deformation limiting blocks 4, the anti-deformation limiting blocks 4 include a bottom plate 41, a support plate 42 and an arc-shaped plate 43 arranged above the bottom plate 41, and the upper end of the support plate 42 is welded to the arc-shaped plate 43 , the lower end of the support plate 42 is welded to the bottom plate 41 , and a reinforcing rib 44 is also arranged between the arc-shaped plate 43 and the bottom plate 41 . The arc of the arc plate 43 is consistent with the arc of the pipe diameter to be processed, which is convenient for placing and clamping the pipe. One end of the bottom plate ...

Embodiment 2

[0068] The method of using a pipe anti-deformation welding fixture in this embodiment to prevent pipe deformation includes the following steps:

[0069] 1) Positioning and angle adjustment of pipe fittings:

[0070] Fix the two ends of the part to be processed of the main pipe fitting or the branch pipe fitting to the fixing device 2 and the adjusting device 3 at both ends of the support 1 respectively, and adjust the angle and position of the pipe fitting through the adjusting device 3;

[0071] 2) Arrange the position of the anti-deformation limit block 4:

[0072] In advance, judge which direction the pipe fitting will deform and move toward the support 1 according to the position where the pipe fitting needs to be subjected to thermal processing such as plasma cutting and welding. After determining the deformation direction of the pipe fitting, make the bending part of the reverse deformation limit block 411 is located on the support 1 on the side opposite to the deformat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com