A kind of manufacturing method of flat electric welding rod and its manufacturing equipment

A manufacturing method and technology for manufacturing equipment, which can be applied to other manufacturing equipment/tools, welding equipment, manufacturing tools, etc., can solve problems such as unsuitable manufacturing of flat welding electrode products, and achieve strong functional practicability, simple processing technology, and automation. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

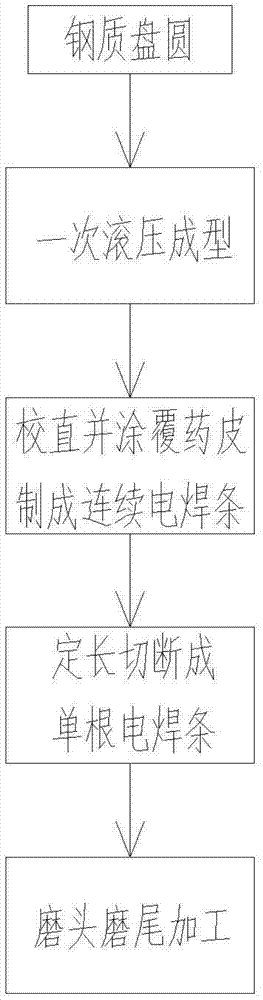

[0041] Such as figure 1 Shown, the manufacture method of a kind of flat welding electrode that the present invention relates to, comprises steps as follows:

[0042] 1. Use a rolling device to roll the steel disc 6 with a circular cross-section into a coiled welding core wire rod 14 with a flat cross-section; the cross-sectional diameter of the steel disc 6 is Φ3-Φ10mm.

[0043] 2. Use the straightening pressure coating device to straighten the welding core wire rod 14 and coat the coating to make a continuous electrode with coating; when coating the coating, adjust the push material of the coating device of the straightening pressure coating device Feed speed, match the feeding speed of the pushing material with the wire feeding speed of the straightening device of the straightening pressure coating device, so as to achieve smooth and tight coating of the electrode coating and high yield.

[0044] 3. The made continuous electrode directly enters the electrode cutting device,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com