Online main drainage pump water suction kettle anti-blocking dredging device for coal mine

A technology of water absorbing tap and dredging device, which is applied in drainage, safety device, cleaning method using liquid, etc., can solve the problems of affecting the normal drainage of the mine, the water pump cannot work normally, and the labor intensity is high, so as to reduce the labor workload of workers, The effect of reducing labor and cost of workers and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

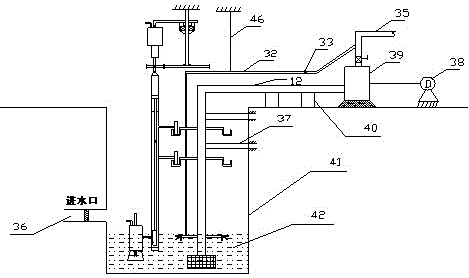

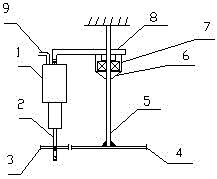

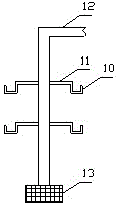

[0026] Embodiment 1: The anti-blocking and dredging device includes: a driving part, an arc guide slideway, a vertical guide slideway, a stirring sand discharge pump, a high-pressure water jet device, an electric control system and a control valve group; the transmission shaft of the drive part and the The fixed boom connection of the vertical guide slideway, the fixed roller of the vertical guide slideway is located in the slideway groove of the arc guide slideway, and the stirring sand discharge pump is also connected to the vertical guide slideway, and the lower end of the vertical guide slideway It is connected with a high-pressure water jet device; the arc guide slideway and the high-pressure water jet device are respectively connected with the suction pipe of the main drainage pump, and the suction pipe plays a stabilizing role; the power actuator in the device is connected with the electric control system and the control valve group. The power actuators described are: dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com