Negative-pressure quilt net wire compaction bag

A negative pressure cotton and mesh technology, applied in textiles and papermaking, non-woven fabrics, household appliances, etc., can solve the problems of time-consuming, labor-intensive and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

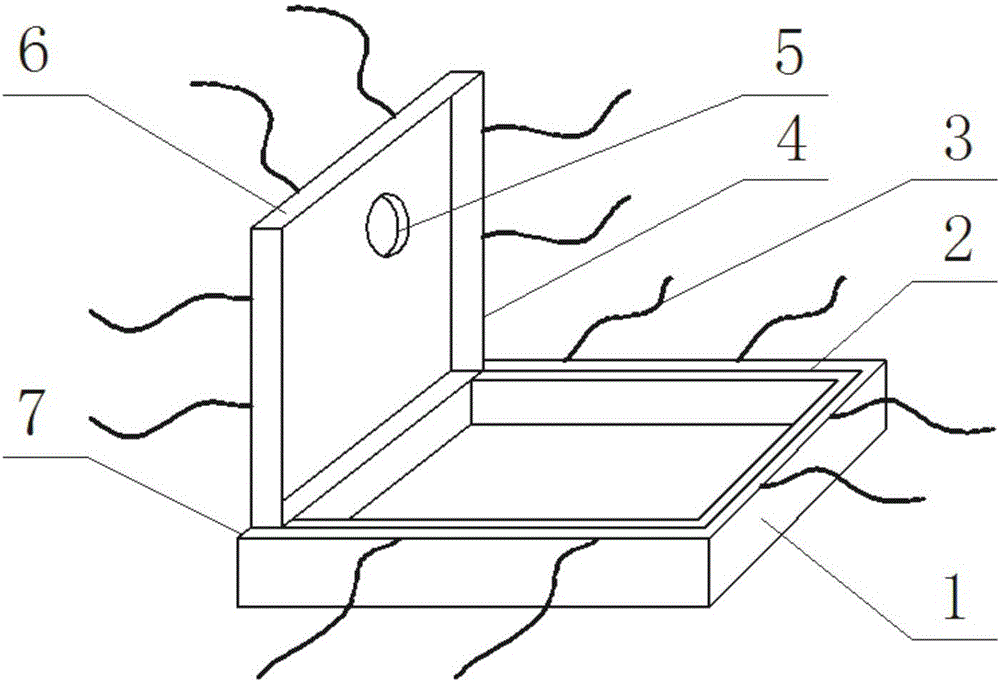

[0018] Such as Figures 1 to 7 As shown, the negative pressure quilt net wire compression bag of the present invention mainly includes a quilt bag body and an air extraction valve.

[0019] The quilt bag body 7 includes a square bag bottom 1 and a bag surface 6, the bottom of the bag and the bag surface are connected as one by a corresponding side, the other three sides of the upper surface of the bag bottom are provided with sealing sockets 2, and the other three sides of the lower surface of the bag surface are provided with There are sealing inserts 4 corresponding to the sealing socket; two total of six pairs of fastening straps 3 are respectively installed on the corresponding positions on the bottom of the bag and the other three sides of the bag surface; the exhaust valve is installed on the On the quilt bag body.

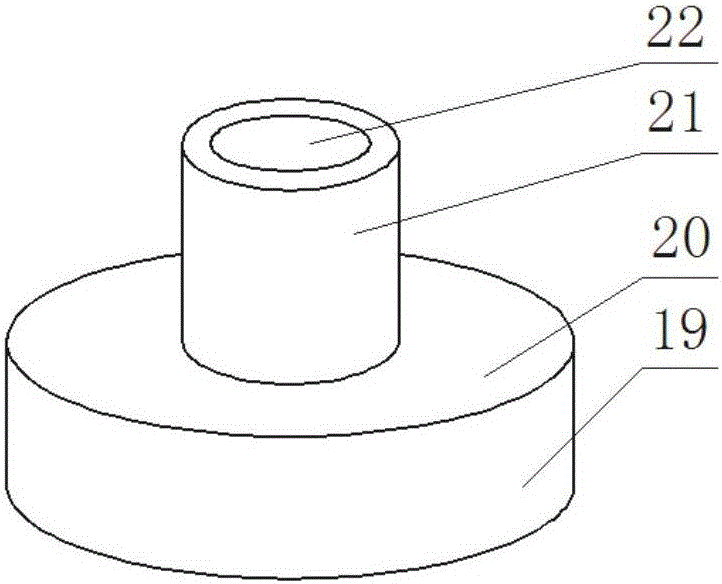

[0020] The air extraction valve is a one-way ventilation valve that automatically closes under negative pressure, which allows the gas outside the valve to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com