Folding type cotton film-mulching seeder based on machine-harvested cotton

A folding, machine-picked cotton technology, which is applied in the directions of fertilizer and seeding equipment, planting methods, excavation/covering ditches, etc., can solve the problems of complex operability, poor machine passability, and large impact on ground flatness, etc., to achieve The effect of cost reduction, work efficiency improvement and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific structure of the present invention is further described below in conjunction with the embodiment given with accompanying drawing.

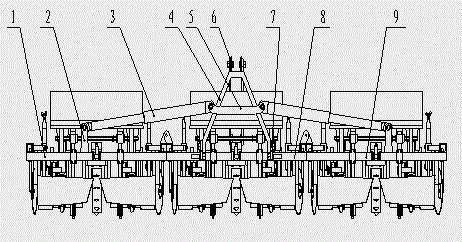

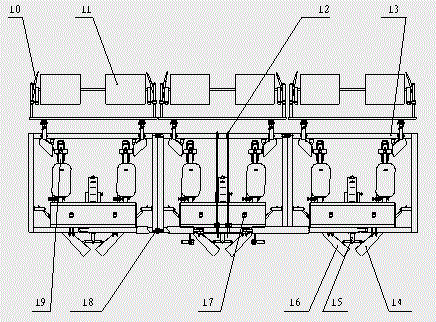

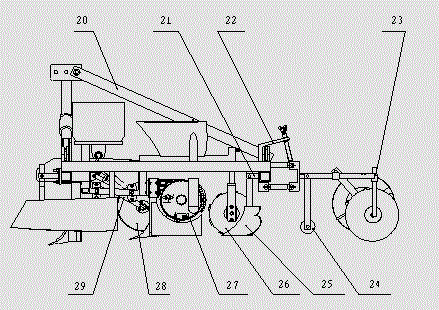

[0019] As shown in the accompanying drawings, a kind of folding cotton-covered planter based on machine-picked cotton of the present invention has a suspension bracket 4, and the suspension bracket 4 is hung with a machine tool frame 8 through the suspension connecting plate 7, and the top of the suspension bracket 4 is provided with There is an upper connection lug 6, and a lower connection lug 12 is arranged on the rear beam of the machine frame 8, and a diagonal tie rod 20 is connected between the upper connection lug 6 and the lower connection lug 12. It is characterized in that: the machine frame 8 Both sides are respectively equipped with the left machine tool frame 1 and the right machine tool frame 9 through frame connecting pins 18, and the upper ends of the two hydraulic cylinders 3 are connected to the beam 5 upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com