A method for testing the reaction time constant of the main servomotor of a hydroelectric generating set

A main relay and reaction time technology, applied in the direction of instruments, simulators, control/regulation systems, etc., can solve the problem that the simulation models of the turbine and the regulation system do not match, affect the accuracy of the power system, and fail to operate the turbine generator set. The problem of effective measurement of the relay response time constant, etc., to achieve the effect of facilitating accurate modeling and simulation, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

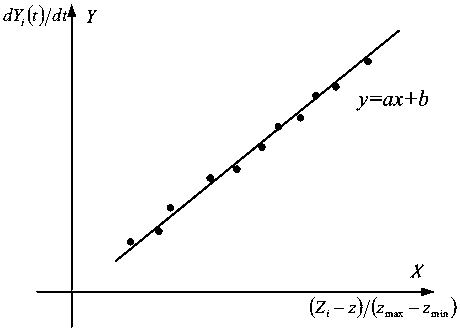

Image

Examples

Embodiment Construction

[0024] A method for testing the reaction time constant of a main servomotor of a hydroelectric generating set, comprising the following steps:

[0025] Step 1. Make sure that the working gate of the water inlet of the turbine diversion tunnel is down, the operating oil source of the working gate is closed, the volute drains without water pressure, and the operating oil source of the turbine governor is opened, and the servomotor lock spindle is pulled out; this step is to ensure The safety measures in the subsequent steps are to ensure that there is no water pressure in the water turbine diversion tunnel, penstock and turbine volute by dropping the working gate of the water inlet. When the turbine guide vane moves, the turbine generator set will not rotate.

[0026] Step 2. Short-circuit the "closed" signal line of the main switch of the unit on the governor, so as to simulate the grid-connected operation state of the governor, and switch the governor to the "automatic" operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com