Clamp used for tension-torsional fatigue performance test of samples of micron-grade sizes

A fatigue performance, micron-level technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problem that the coaxiality of the clamping does not meet the requirements of the multi-axis fatigue performance test of tension and torsion, the clamping is unreliable, and the processing accuracy of the fixture is high. The problem is to improve the clamping accuracy and sample clamping efficiency, the positioning and clamping operation is convenient, and the structure is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

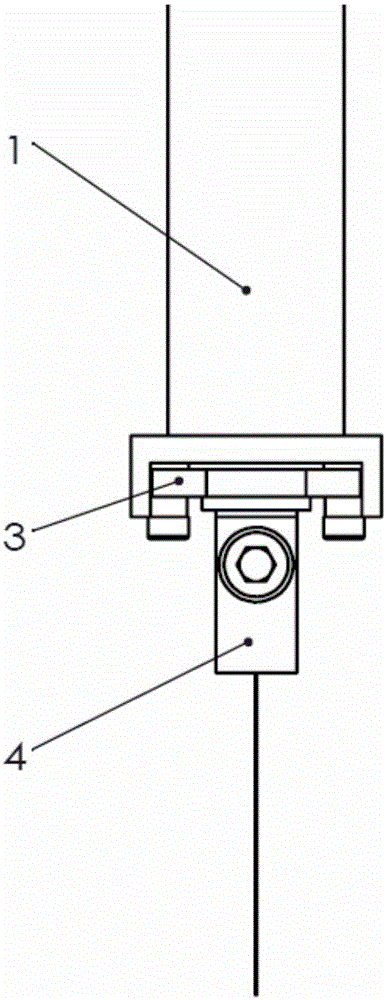

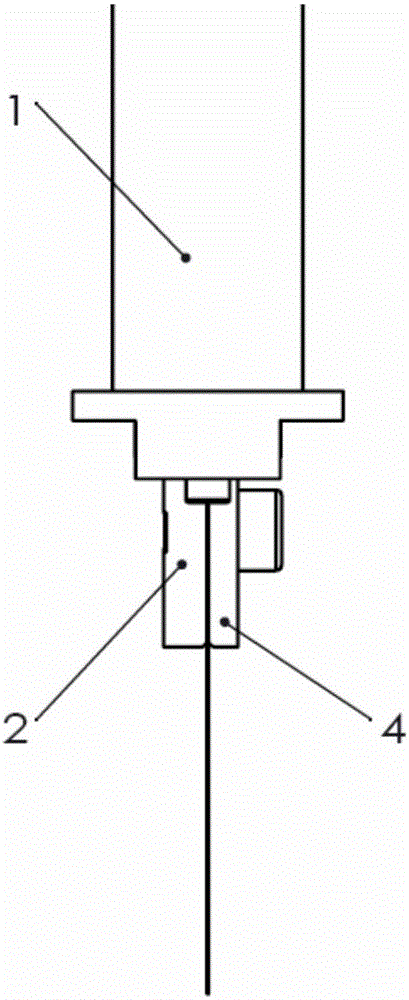

[0024] Such as figure 1 , 2 As shown, a fixture for tensile, torsion or multi-axial tensile torsion fatigue test of 100 μm grade wire or fiber sample, including an actuating shaft 1, which is inserted into the actuating shaft and positioned coaxially with the actuating shaft for clamping the sample The detachable main clamp block 2 and the pressure plate 4 that cooperates with the main clamp block 2 to clamp the sample are installed on the main clamp block so that the main clamp block 2 is fixed to the lock nut 3 of the actuating shaft 1.

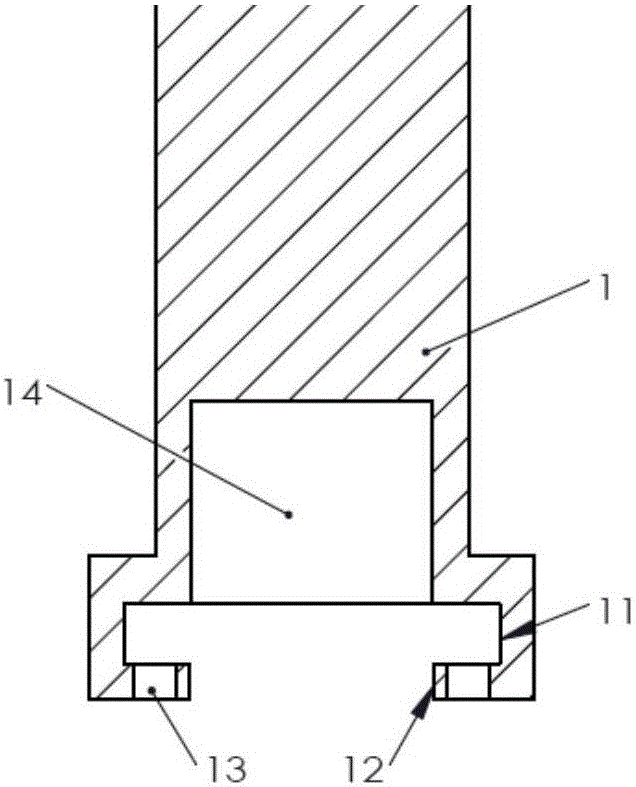

[0025] Such as image 3 As shown, the main structural shape of the actuating shaft 1 is a stepped optical axis, the small diameter end of the stepped shaft is connected to the sensor or the motor, the large diameter end of the stepped shaft is the main clamping block installation end, and the main clamping block 2 is installed and fixed at this end. The mounting end of the main clamping block is provided with a front and rear through rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com