Hot blast stove for poultry house

A hot stove and poultry house technology, applied in the field of poultry breeding, can solve the problems of many human operations, waste of energy, low intelligence, etc., and achieve the effect of saving energy and avoiding local damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

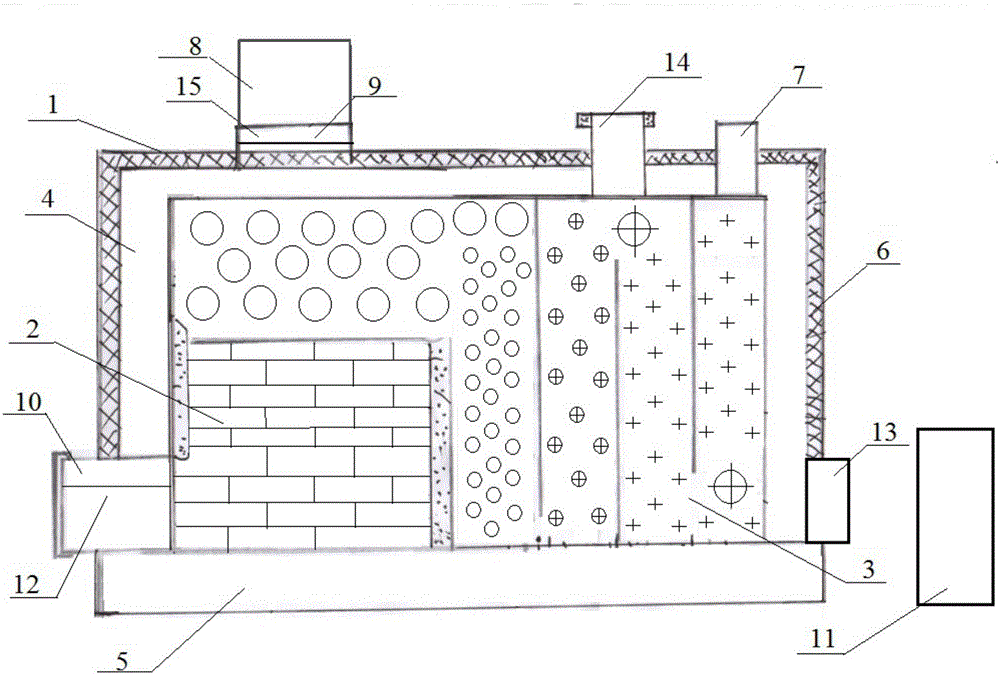

[0023] The purpose of this embodiment is to provide a hot stove for poultry houses with efficient heat exchange function.

[0024] This embodiment specifically provides a hot air stove for a poultry house, including a housing 1, a combustion chamber 2, a heat exchange chamber 3, a hot air chamber 4, a dust chamber 5, an insulation layer 6, a flue 7, a hot air passage 8, and an air outlet 9. Combustion-supporting fan 10, coal delivery port 12, air inlet 13; shell 1, insulation layer 6, and the other five sides of hot air chamber 4 except the bottom are arranged layer by layer from outside to inside, and the above-mentioned three-layer structure is arranged in the dust Above the slag chamber 5; the combustion chamber 2 and the heat exchange chamber 3 are connected, and both are arranged in the closed space formed by the hot air chamber 4 and the dust and slag chamber 5; The hot air chamber 4 is connected to the combustion chamber 2. At the same time, the coal delivery port 12 is...

Embodiment 2

[0038] In this embodiment, except that no filling material is provided in the heat exchange chamber 3 , other structures, technical solutions, implementation methods and technical effects are the same as those in Embodiment 1.

Embodiment 3

[0040] In this embodiment, except that no baffle plate is provided in the heat exchange chamber 3 , other structures, technical solutions, implementation methods and technical effects are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com