Floor slab reinforcement protective layer double-control precast concrete cushion block and installation method thereof

A steel protective layer and prefabricated concrete technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of cumbersome installation, difficulty in guaranteeing construction quality, single function, etc., and achieve low installation strength, simple structure, and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Now in conjunction with accompanying drawing, the present invention will be further described.

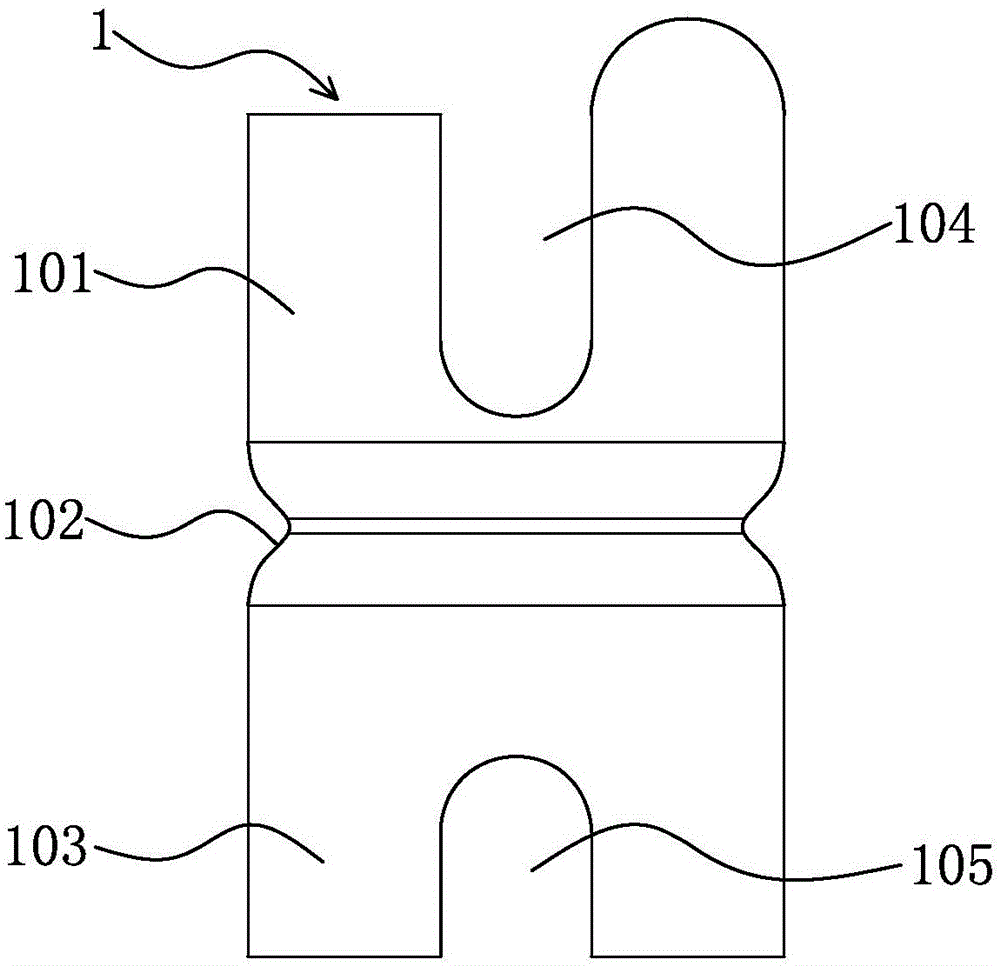

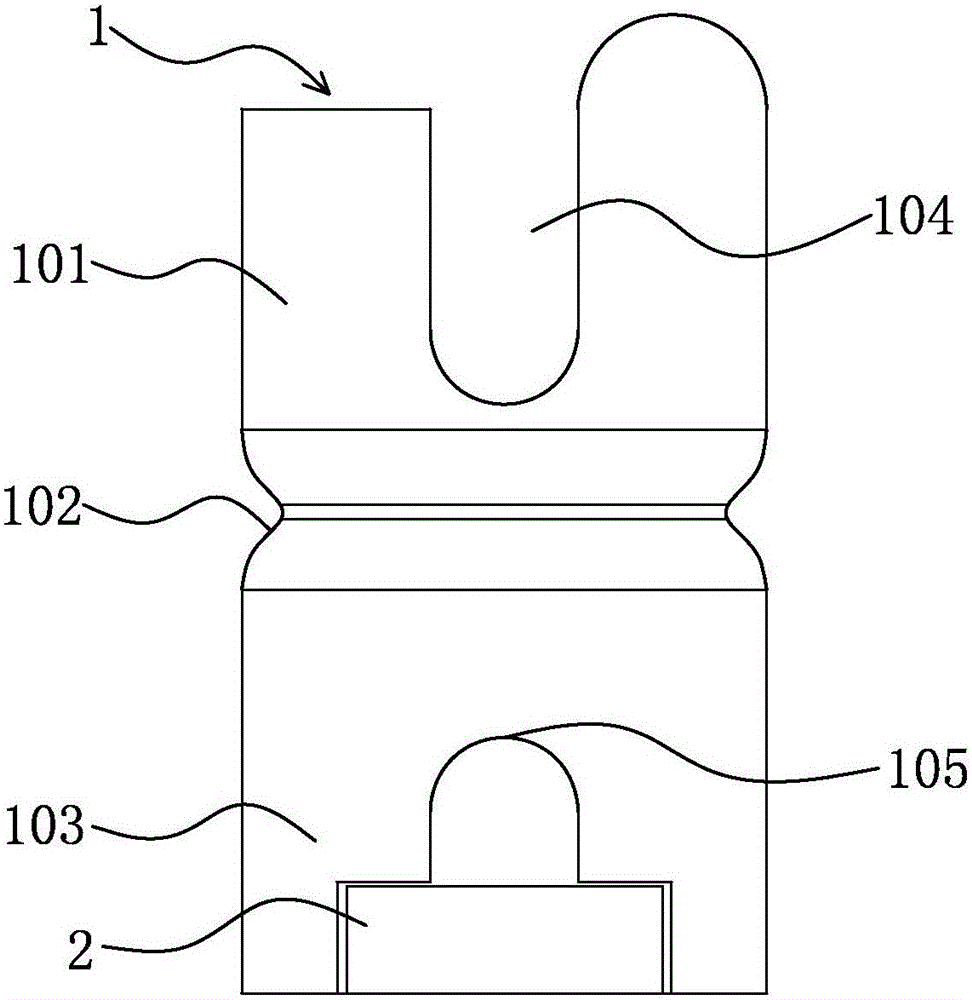

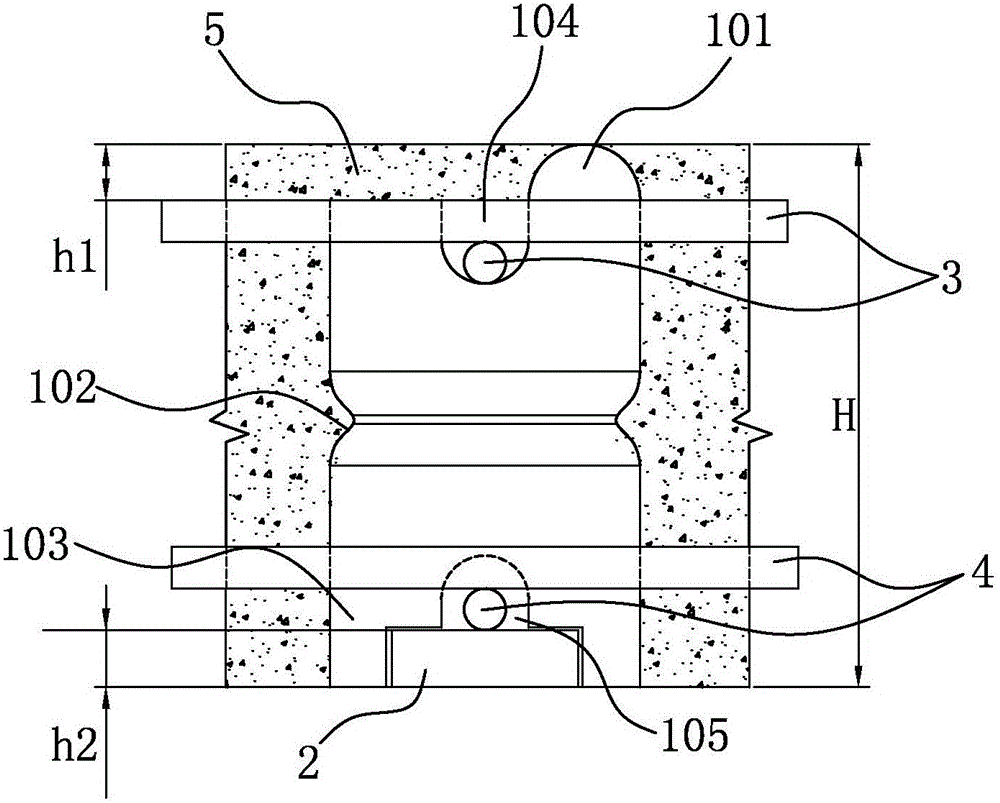

[0017] Such as figure 1 , image 3 As shown, the double-controlled prefabricated concrete block of the reinforced protective layer of the floor slab, referred to as "protective layer block 1", its main body is an H-shaped concrete piece, including a pair of upper support feet 101 and a pair of lower support feet 103, An upper support notch 104 is provided between the two upper support legs, and a lower support notch 105 is provided between the two lower support legs. It is a convex arc surface, and the ends of the short upper supporting feet and the two lower supporting feet are planes. The vertical height between the top of the long upper supporting foot and the bottom of the lower supporting foot is the floor thickness H, the vertical height between the top of the long upper supporting foot and the top of the short upper supporting foot is the thickness h1 of the protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com