Lightweight partition board with net rack and fiber-reinforced hollows and splicing method thereof

A light-weight partition board and fiber-reinforced technology, which is applied to building components, buildings, building structures, etc., can solve the problems of difficult to decompose chemical components, prolong the construction period, and high energy consumption, so as to achieve easy control of building quality and solve the problem of wall Cracks, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

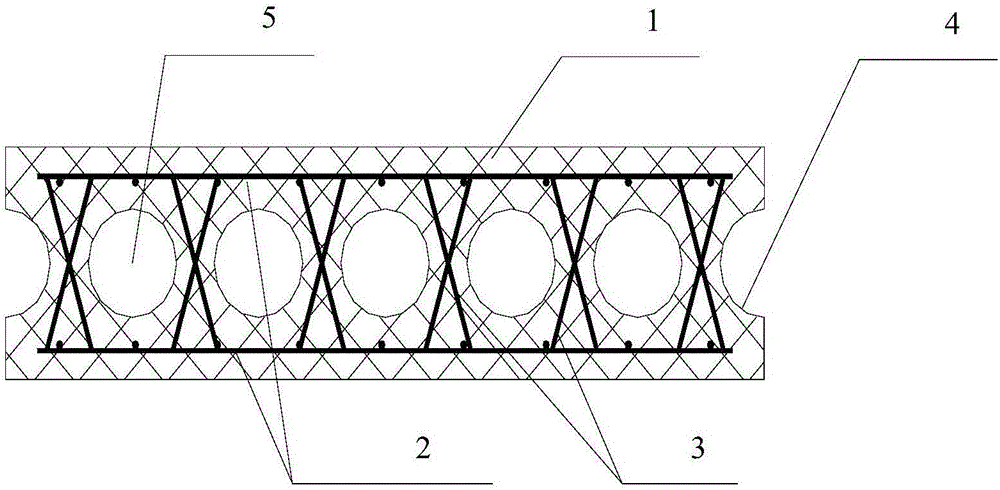

[0024] Such as figure 1 Shown: a hollow lightweight partition wall panel with grid frame and fiber reinforcement, including panel body 1, steel wire mesh sheet 2, oblique insertion rib 3, positioning groove 4, cavity 5, wherein oblique insertion rib 3 and upper and lower steel wires The mesh 2 is fixedly connected inside the board body 1 to form a space grid. The board body 1 is cast and formed by ceramsite fiber concrete. Since the upper and lower surfaces of the board body 1 are naturally rough, it is helpful for wallboard joints and plastering processes, effectively solving problems such as wall cracks, water seepage, drum shells, etc., and avoiding most of the "common quality problems" of construction , making building quality easier to control.

[0025] Further, the strength level of plate body 1 is not lower than LC7.5, and the bulk density is not more than 15kN / m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com