Masonry filler wall reinforcement and plastering constructional column and construction method thereof

A technology for filling walls and structural columns, which is applied to building structures, walls, building components, etc. It can solve problems such as secondary damage to wall blocks, difficult quality control, and uneven walls, so as to save construction time and materials , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

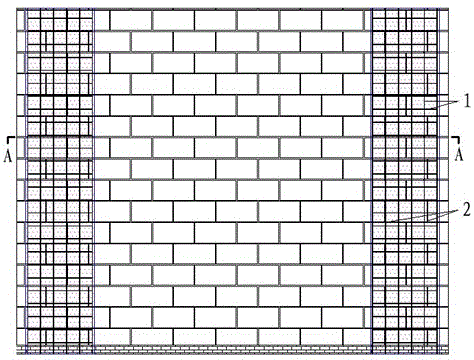

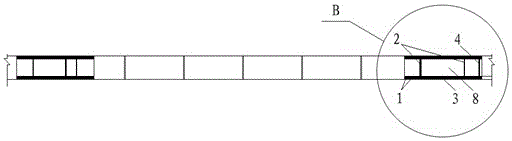

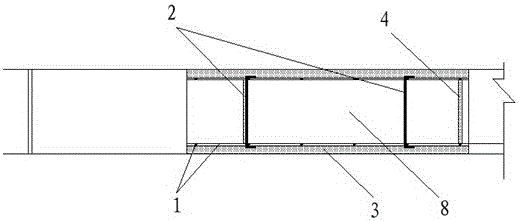

[0031] see figure 1 , the present invention is a masonry filled wall reinforced plastered construction column, including masonry, both sides of the masonry are provided with reinforcement mesh 1, and the reinforcement mesh 1 is connected with masonry pre-embedded steel bars that run through the masonry 2. The upper and lower ends of the reinforcement mesh 1 are fixedly connected with the upper flat steel 5 and the lower flat steel 9 respectively, the upper insertion rib 6 is fixedly connected with the upper flat steel 5, the lower insertion reinforcement 7 is fixedly connected with the lower flat steel 9, and the reinforcement mesh 1 Both inside and outside are covered with mortar 3.

[0032] The masonry consists of 8 stacked blocks.

[0033] Masonry mortar 4 is applied between the blocks 8 .

[0034] The masonry pre-embedded steel bars 2 are embedded in the masonry mortar 4 .

[0035] The two ends of the masonry pre-embedded steel bars 2 are provided with hooks.

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com