Gradient-enhanced ceramic particle Cu heat sink and preparation method thereof

A ceramic particle and gradient technology is applied in the field of ceramic particle gradient enhanced Cu heat sink and its preparation, which can solve the problem that the thermal expansion coefficients of chip materials cannot be matched at the same time, and achieve the effects of improving service life, low preparation temperature and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the above-mentioned ceramic particle gradient reinforced Cu heat sink mainly includes two stages of green compact preparation and sintering to prepare the heat sink. The sintering preparation of the heat sink is divided into three processes: preheating, reaction and densification, specifically including the following steps:

[0036] Step 1. Compaction preparation:

[0037] Weigh 2 or 3 groups of 40-80vol.% Cu powder and 20-60vol.% reactant powder for preparing ceramic particles and add them to the mixer respectively, after mixing evenly, add them to the mold respectively, and press to form, obtain compacts of 2 or 3 different compositions;

[0038] Among them, the reactant powder used to prepare ceramic particles is a mixture of Ti powder and B powder, or Ti powder and B powder 4 The mixture of C powder, when the reactant powder is a mixture of Ti powder and B powder, the material ratio of Ti powder and B powder is 1:2; when the reactant powde...

Embodiment 1

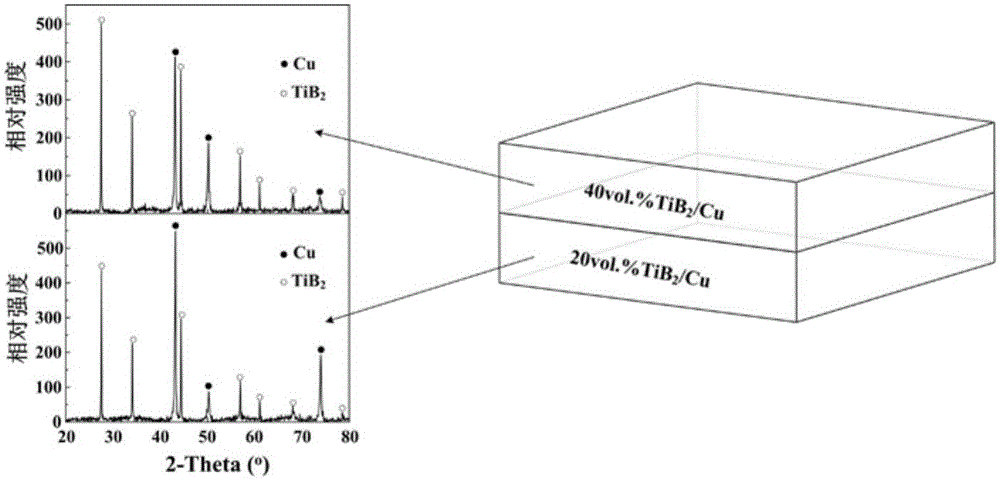

[0054] Gradient reinforced Cu heat sink with ceramic particles, the composition of the first functional layer is: 40vol.%TiB 2 / Cu; the composition of the second functional layer is: 20vol.%TiB 2 / Cu.

[0055] above TiB 2 Preparation method of ceramic particle gradient reinforced Cu heat sink:

[0056] Step 1. Put 74.83g of Cu powder with a particle size of 45μm, 17.26g of Ti powder with a particle size of 20μm, and 7.91g of B powder with a particle size of 1μm into a mixer (rotating at a speed of 10r / min) for 7 hours; mix 88.80g Cu powder with a particle size of 50 μm, 7.68 g of Ti powder with a particle size of 25 μm, and 3.52 g of B powder with a particle size of 5 μm were put into a mixer (rotating speed: 50 r / min) and mixed for 6 hours; The materials are respectively put into stainless steel molds and pressed into billets;

[0057] Step 2. Stack the two compacts in the graphite mold in the sintering furnace. After vacuuming, inject 1 atmosphere of high-purity nitrogen...

Embodiment 2

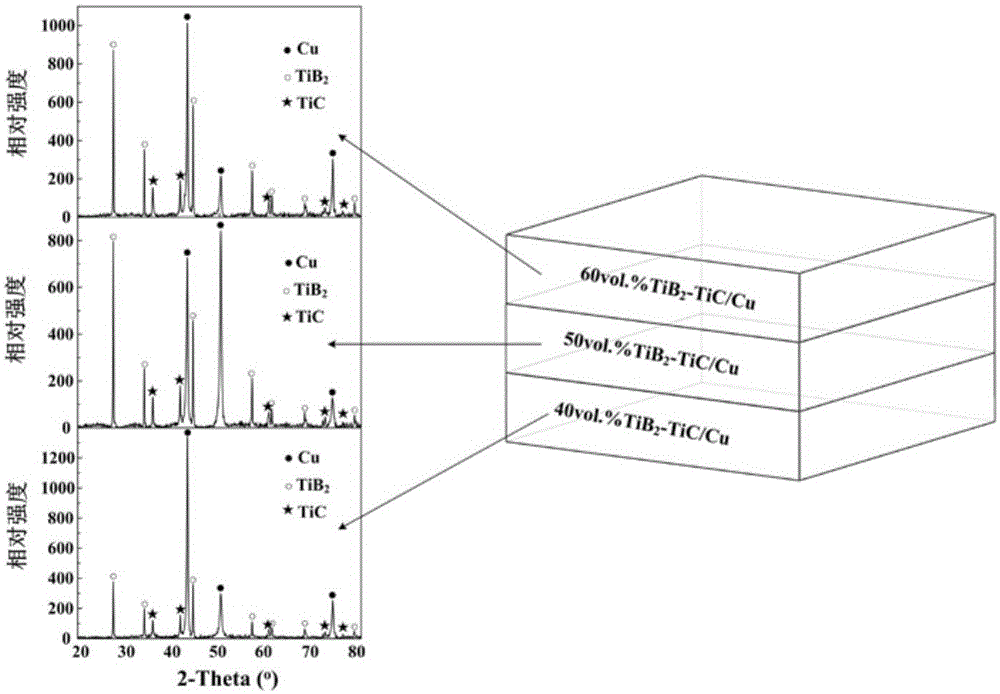

[0062] Ceramic particle gradient reinforced Cu heat sink, the composition of the first functional layer is: 60vol.%TiB 2 -TiC / Cu; the composition of the second functional layer is: 50vol.%TiB 2 -TiC / Cu; the composition of the third functional layer is: 40vol.%TiB 2 -TiC / Cu.

[0063] The aforementioned TiC-TiB 2 Preparation method of ceramic particle gradient reinforced Cu heat sink:

[0064] Step 1: 56.13g of Cu powder with a particle size of 45μm, 31.70g of Ti powder with a particle size of 3.5μm and 12.17g of B with a particle size of 5μm 4 Put the C powder into the mixer (30r / min) and mix for 7 hours; put 65.74g of Cu powder with a particle size of 25μm, 24.75g of Ti powder with a particle size of 25μm and 9.51g of B with a particle size of 3.5μm 4 Put C powder into the mixer (rotating speed is 40r / min) and mix for 8 hours; 74.22g of Cu powder with a particle size of 25μm, 18.63g of Ti powder with a particle size of 20μm and 7.15g of B with a particle size of 5μm 4 C p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com