Eddy flow dehydration plant

A cyclone dehydration and drainage technology, which is applied in the direction of multi-stage series refining process treatment, etc., can solve the problems of limited application, poor dehydration quality and stability, etc., to improve oil purity, improve dehydration efficiency, and dehydration treatment. effect of time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

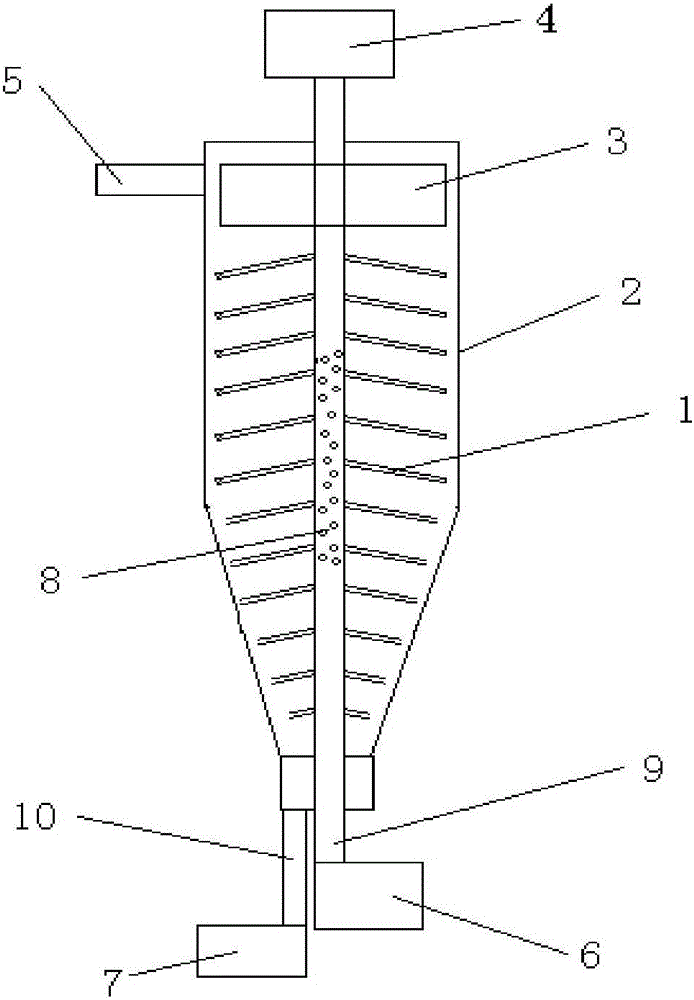

[0026] see figure 1 , a cyclone dehydration device, including a housing 2, a transmission shaft, a movable leaf wheel 3, an electrode plate 1, a liquid inlet pipe 5, an oil collecting pipe 9 and a drain pipe 10, the liquid inlet pipe 5 is arranged on the upper part of the housing, The oil collecting pipe 9 and the drain pipe 10 are arranged at the lower part of the casing, the transmission shaft extends into the casing and connects with the movable impeller 3, the liquid inlet pipe 5 corresponds to the position of the movable impeller 3, and the One end of the oil collecting pipe 5 extends into the housing, the electrode plate 1 is arranged on the oil collecting pipe, and a number of oil collecting pipes are distributed on the oil collecting pipe, and the electrode plate 1 and the oil collecting holes 8 are located in the housing 2, the other end of the oil collecting pipe extends out of the casing.

[0027] The moving leaf wheel 3, the transmission shaft and the section wher...

Embodiment 2

[0036] A swirl dehydration device, comprising a housing 2, a transmission shaft, a movable leaf wheel 3, an electrode plate 1, a liquid inlet pipe 5, an oil collecting pipe 9 and a drain pipe 10, the liquid inlet pipe 5 is arranged on the upper part of the housing, and the The oil collecting pipe 9 and the drain pipe 10 are arranged at the lower part of the casing, the transmission shaft extends into the casing and connects with the moving impeller 3, the liquid inlet pipe 5 corresponds to the position of the moving impeller 3, and the collecting One end of the oil pipe 5 extends into the housing, the electrode plate 1 is arranged on the oil collecting pipe, and a number of oil collecting pipes are distributed on the oil collecting pipe, and the electrode plate 1 and the oil collecting holes 8 are located in the housing 2 Inside, the other end of the oil collecting pipe extends out of the housing.

[0037] The moving leaf wheel 3, the transmission shaft and the section where t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com