Preparation method and application of Prussian-blue-nanocrystal-loaded graphene composite material

A technology of Prussian blue and composite materials is applied in the preparation of graphene composite materials and the application field of supercapacitors, which can solve the problems of short cycle life, poor conductivity and small capacitance, and achieve simple operation, simple method, and reproducibility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

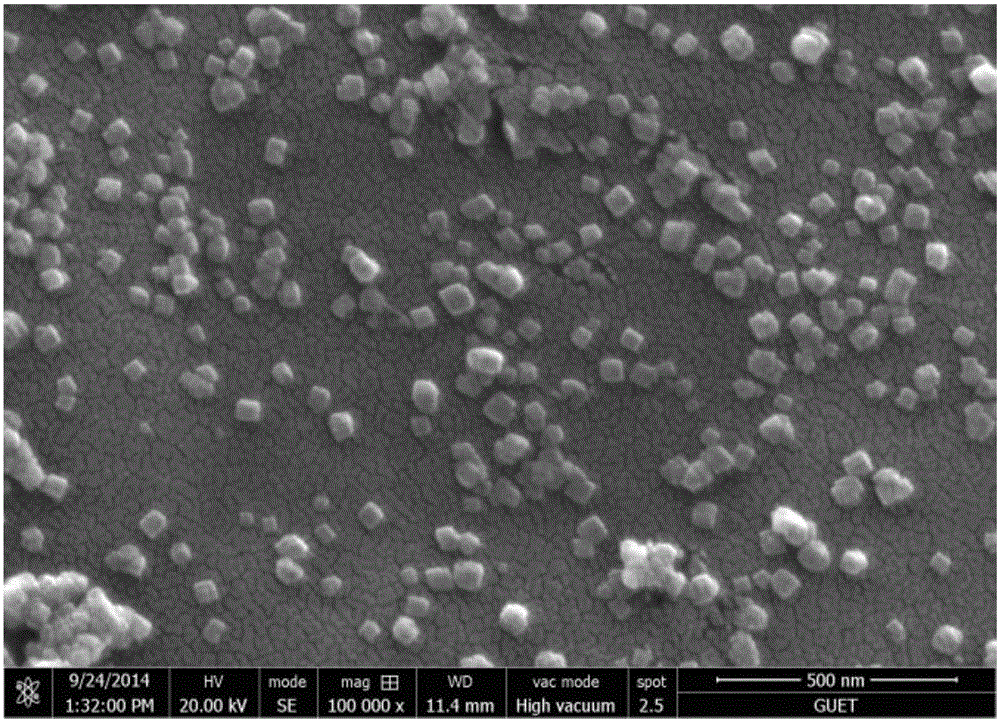

Embodiment 1

[0034] (1) Prepare 50mL of 0.1M aniline + 0.1M HCl solution

[0035] (2) Ultrasonic dispersion of 0.01g of graphene oxide in the solution of step (1) is denoted as M

[0036] (3) Preparation of 0.02M Fe(NO 3 ) 3 +0.02M K 3 Fe(CN) 6 +0.1M HCl solution 50mL, recorded as solution N

[0037] (4) Slowly add the solution of step (3) dropwise to the solution of step (2), and stir the solution of step (2) with a magnetic stirrer;

[0038] (5) After the dropwise addition is completed, let the solution react for 12 hours, filter, wash and dry.

[0039] (6) Get 0.1g graphene-Prussian blue nanocrystalline composite material and ultrasonically disperse it in 1mL N,N-dimethylformamide solution, then add 50 μ L 5% Nafion solution to this solution, take this nanocomposite material Drop 10 μL of the suspension on the surface of the glassy carbon electrode, and dry it under an infrared lamp;

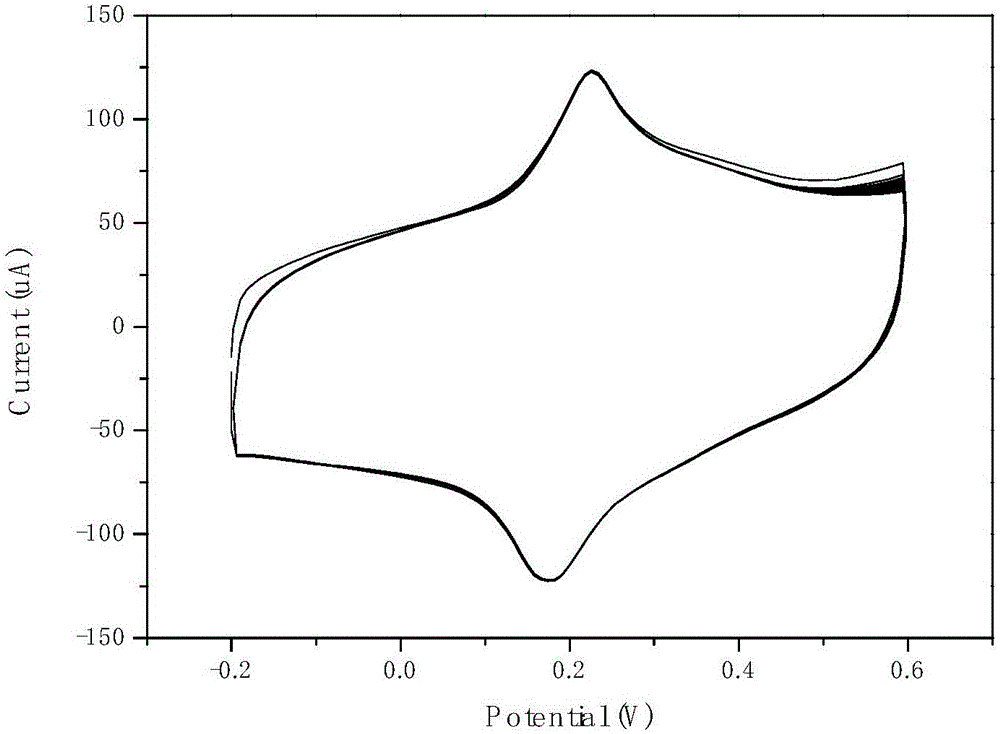

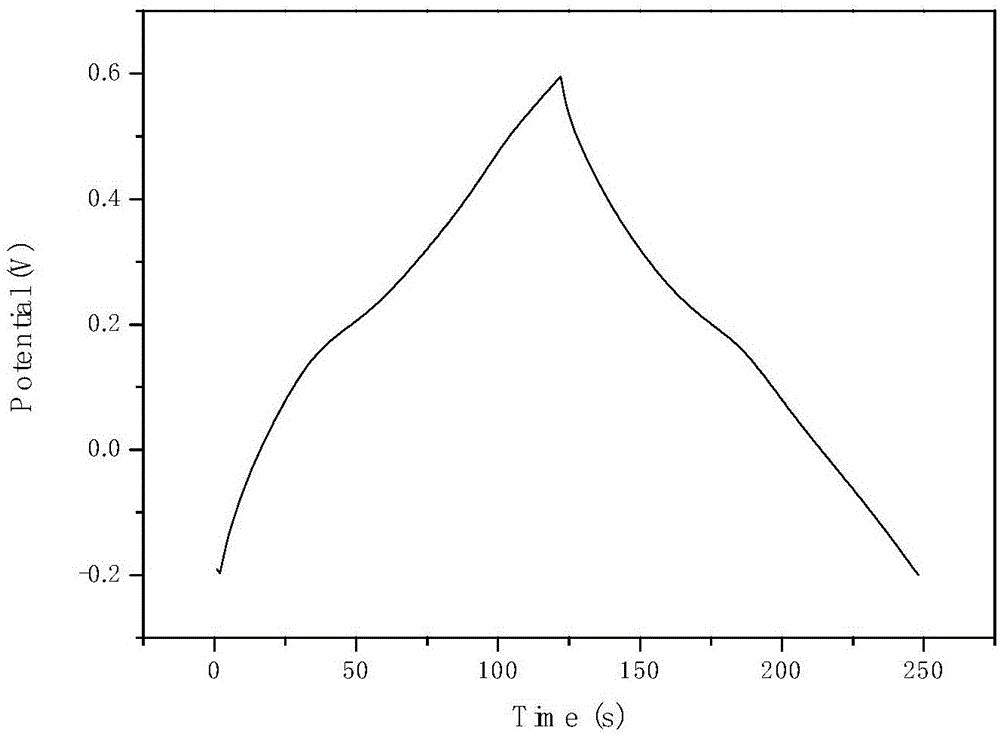

[0040] (7) The prepared electrode was used as an electrode of a supercapacitor, and an electroc...

Embodiment 2

[0042] (1) Prepare 50mL of 0.1M aniline + 0.1M HCl solution

[0043] (2) Get 0.02g of graphene ultrasonically dispersed in step (1) solution, denoted as M

[0044] (3) Preparation of 0.02M Fe(NO 3 ) 3 +0.02M K 3 Fe(CN) 6 +0.1M HCl solution 50mL, recorded as solution N

[0045] (4) Slowly add the solution of step (3) dropwise to the solution of step (2), and stir the solution of step (2) with a magnetic stirrer;

[0046] (5) After the dropwise addition is completed, let the solution react for 12 hours, filter, wash and dry.

[0047] (6) Get 0.1g graphene-Prussian blue nanocrystalline composite material and ultrasonically disperse it in 1mL N,N-dimethylformamide solution, then add 50 μ L 5% Nafion solution to this solution, take this nanocomposite material Drop 10 μL of the suspension on the surface of the glassy carbon electrode, and dry it under an infrared lamp;

[0048] (7) The prepared electrode was used as an electrode of a supercapacitor, and an electrochemical tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com