Regenerated papermaking wastewater treatment system

A wastewater treatment system and waste paper papermaking technology, applied in the field of papermaking, can solve problems such as increased soluble COD, increased difficulty in papermaking wastewater treatment, and reduced water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

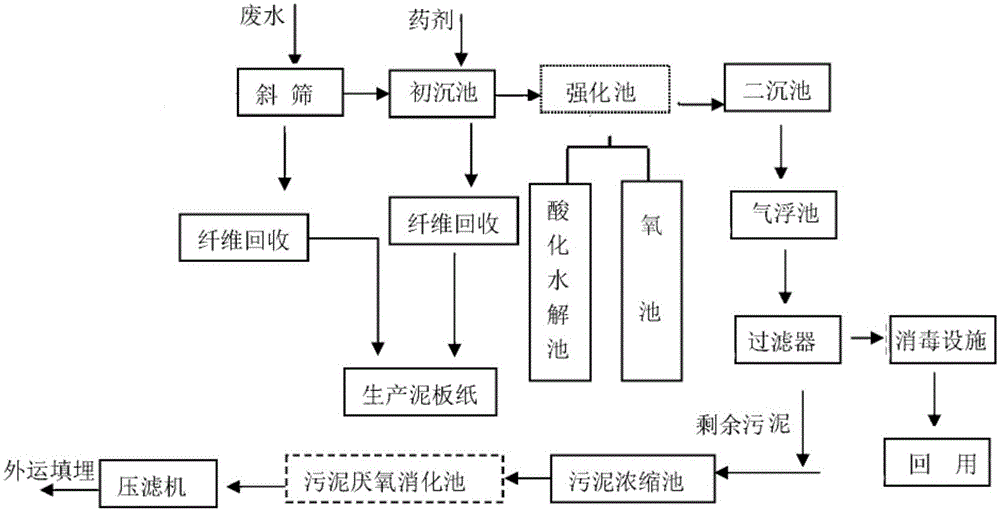

[0013] Such as figure 1 As shown, it is a structural schematic diagram of an embodiment of the present invention, a waste paper papermaking wastewater treatment system, including inclined screen, primary sedimentation tank, strengthening tank, secondary sedimentation tank, air flotation tank, filter, sludge concentration tank, sewage Mud anaerobic digestion tank and filter press, the inclined screen, primary settling tank, strengthening tank, secondary settling tank and air flotation tank are connected through pipelines in sequence, and the sludge thickening tank and sludge anaerobic digestion tank are connected through pipelines in sequence, The stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com