Electric vehicle body frame

A technology for electric vehicles and car bodies, which is applied to vehicle components, superstructures, subassemblies of superstructures, etc. It can solve the problems of low effective load efficiency and achieve the advantages of ensuring forming quality and connection reliability, reducing weight and consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

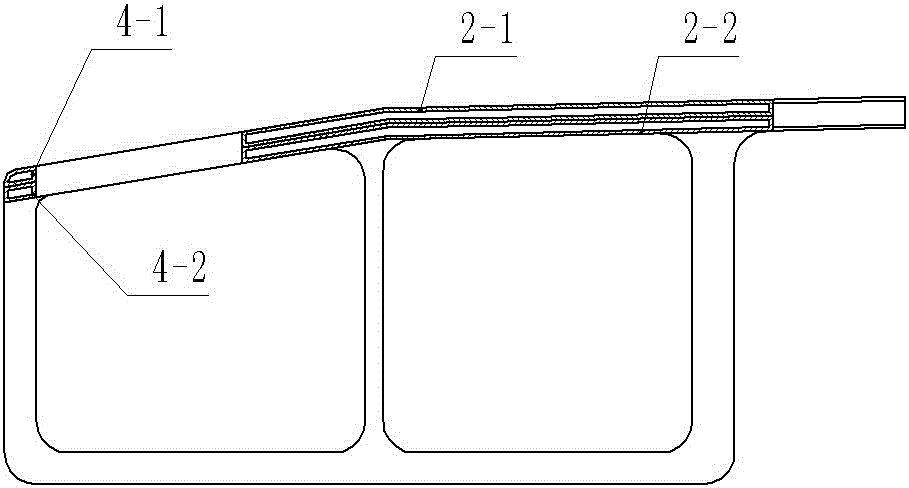

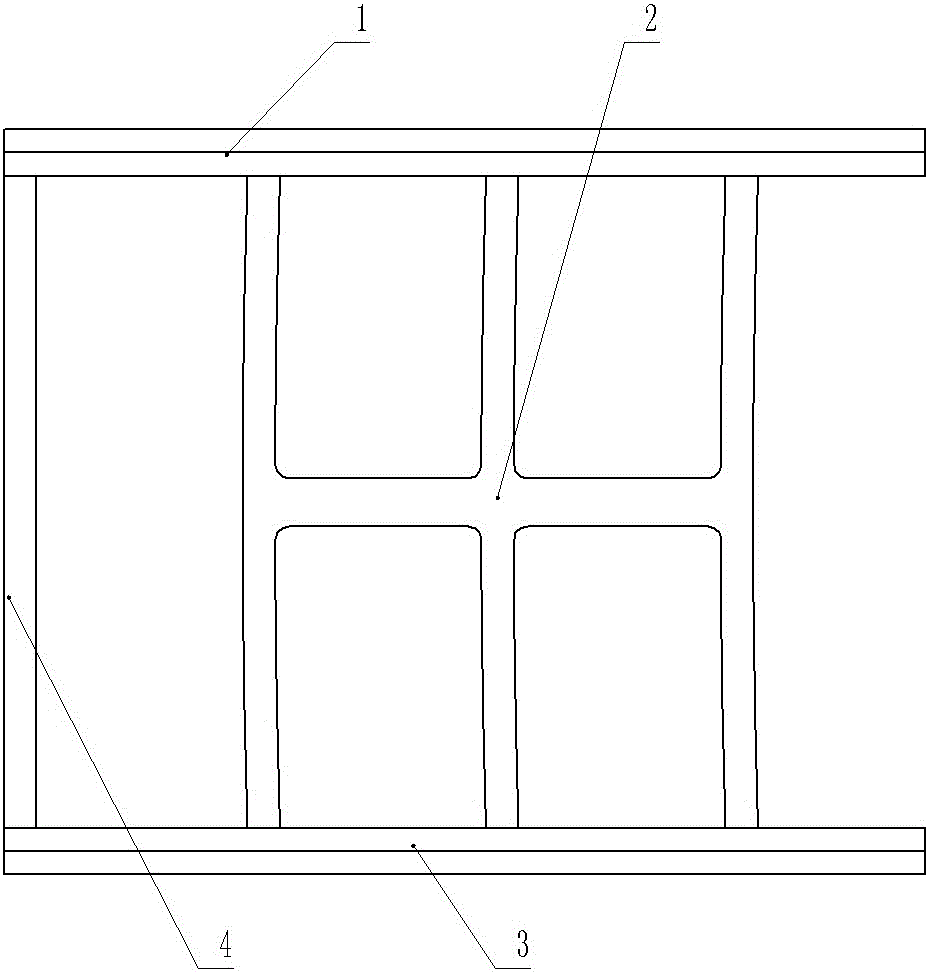

[0009] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0010] Such as figure 1 with figure 2 The shown electric vehicle body frame includes a body frame body, and the body frame body has side body frames arranged on both sides. The side body frame is divided into a left body frame 3 and a right body frame 1. The roof frame and the front car bracket connected with the right side body frame 1; the left side body frame 3 is composed of the left side body outer piece and the left side body inner side piece which are mortised and jointed, wherein the left side body side outer piece There is a positioning tenon joint, and a positioning mortise eye is provided on the inner part of the left car body. The outer part of the left car body and the inner part of the left car body are mortized and connected by screws; The outer panel and the inner panel on the right side of the body are composed of a positioning mortise joint on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com