Wire cord fabric cutting-off device and technology thereof

A steel cord and cutting technology, which is applied in the field of rubber machinery, can solve problems such as unstable angle accuracy of the cord strip, inaccurate width material size, and tail swing of the cord strip, so as to avoid the tail swing phenomenon, accurate angle accuracy, and precise lengthening The effect of a fixed angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

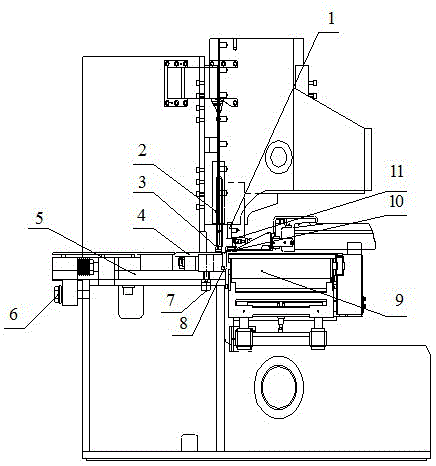

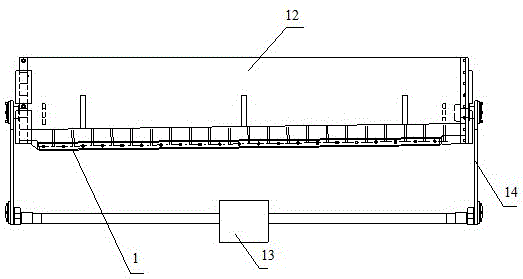

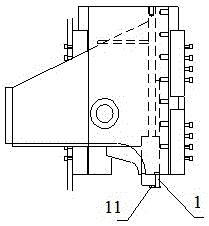

[0036] In order to meet the growing demand for wide-tread tire production, improve the width accuracy of the cut parts, especially the angle accuracy, and increase productivity (14 times / min to 17 times / min), this invention proposes a new type of steel wire Cord cutting device and cutting process. Attached below Figure 1~9 The specific embodiment of the present invention will be further described in detail.

[0037] Such as Figure 1~9 The shown steel cord cutting device includes a cutting knife mechanism, a material pressing mechanism, a conveyor belt mechanism 9, a clamp fixing length mechanism, and a turning plate lifting mechanism.

[0038] The cutter mechanism includes an upper cutter mechanism and a lower cutter mechanism. Upper cutting mechanism such as figure 2 , 3 As shown, it includes an upper knife rest 12, an upper knife 1 installed on the upper knife rest 12, an upper knife driving mechanism, and an upper cutting knife anti-sticking mechanism 11. The upper kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com