Mandrel withdrawing device for forging forming of inner hole profile

A technology for extracting devices and mandrels, applied in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machinery, etc., can solve problems such as inability to extract, damage to the inner surface of the workpiece, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

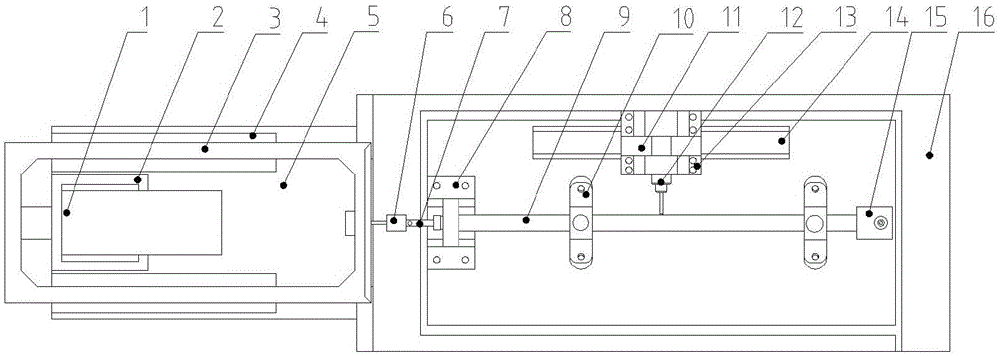

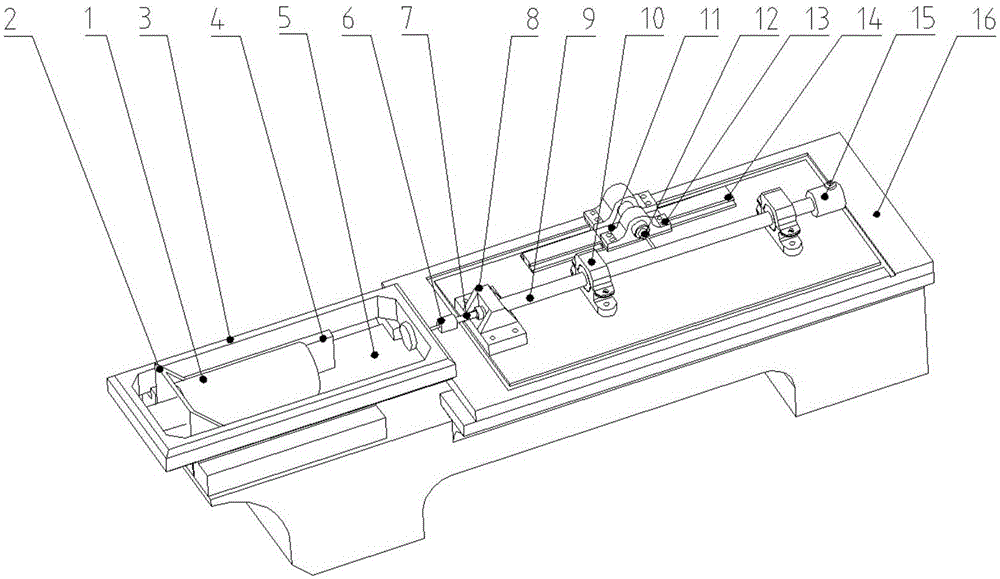

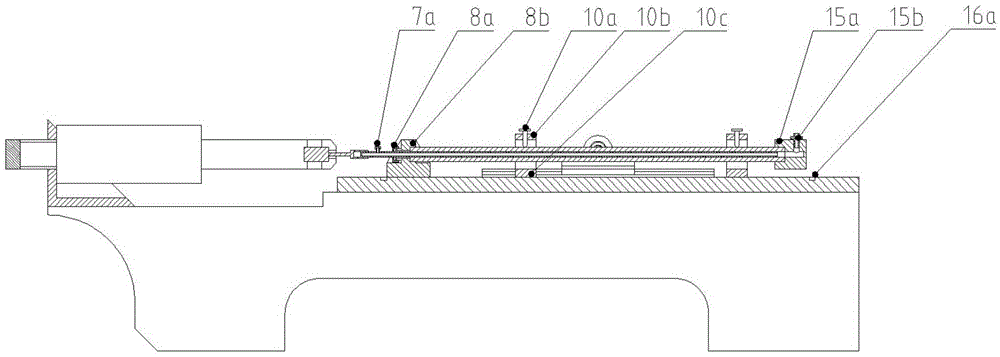

[0026] Such as figure 1 , figure 2 , image 3 As shown, a mandrel extraction device for inner hole profile forging, including a body 5 and a fixed plate 16 connected thereto, a hydraulic cylinder 1 is connected and fixed to the body 5 through a hydraulic cylinder fixing frame 2, the punch of the hydraulic cylinder It is connected with the left end of the pull ring 3, the two sides of the pull ring 3 slide on the pull ring support 4, the right end of the pull ring 3 is connected with one end of the mandrel 7 through a flexible joint 6, the mandrel 7 is covered with a workpiece 9, and the workpiece 9 passes through the workpiece support frame 10 positioning, the left end of the workpiece 9 withstands the end baffle plate 8, the right end of the workpiece 9 is connected to the oil chamber 15, and a vibrator 12 is arranged next to the middle part of the workpiece 9, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com