Method for multistage wet method removal of PM2.5 in industrial tail gas

An industrial tail gas and removal technology, which is applied in the field of gas PM2.5 treatment and multi-stage wet removal of PM2.5 in industrial tail gas, can solve the problem of large fog entrainment, reduction of gas temperature and humidity, and PM2.5 removal. rate reduction and other problems, to achieve the effect of improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

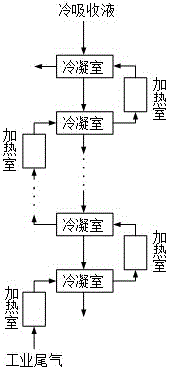

[0028] Example 1: Flue gas treatment PM2.5 pilot project, using a three-stage PM2.5 removal system, the flue gas flow rate is 200~220Nm 3 / h, the inlet temperature is 120~180℃, the amount of cold absorption liquid: 0.01~0.3m 3 / Nm 3 , the direction of cold absorption liquid and flue gas flow adopts such as figure 1 In the countercurrent mode shown, the temperature at the outlet of the gas in each stage of the heating chamber is controlled to be 120~180°C, and the flow rate of the gas in each stage of the condensation chamber is 0.5~3m / s. In this embodiment, the temperature ratio of the outlet temperature of the gas in each stage of the condensation chamber is The temperature of the cold absorption liquid entering the condensation chamber of this stage is 5~30°C higher. The mass fraction of water vapor is in the range of 20% to 30%. The total mass removal rate of PM2.5 in the outlet gas of the third-stage condensation chamber is over 90%.

Embodiment 2

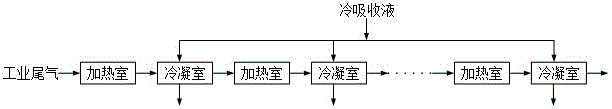

[0029] Embodiment 2: the direction of absorption liquid and flue gas flow adopts such as figure 2 The cross-flow method shown is the same as in Example 1, and the total mass removal rate of PM2.5 in the outlet gas of the third-stage condensation chamber is over 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com