Electric kettle with automatically opening and closing lid based on rate of water temperature change

An automatic opening and closing, electric kettle technology, applied in the direction of boiling water appliances, etc., can solve the problems of short automatic power-off time, non-automatic tripping of temperature control switches, safety accidents, etc., to improve water quality and accurate boiling judgment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

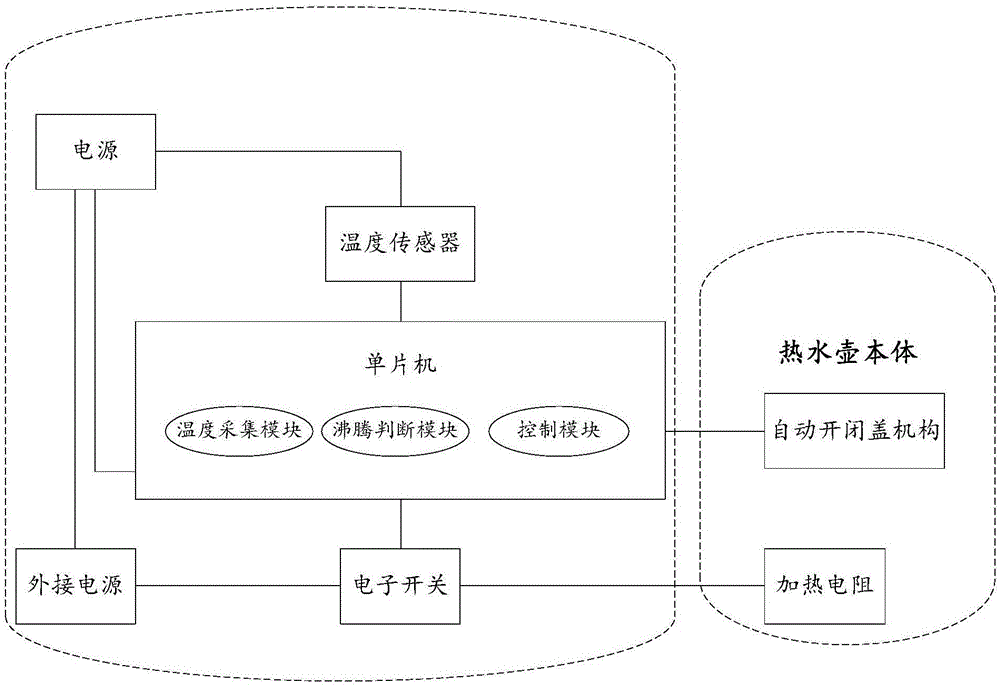

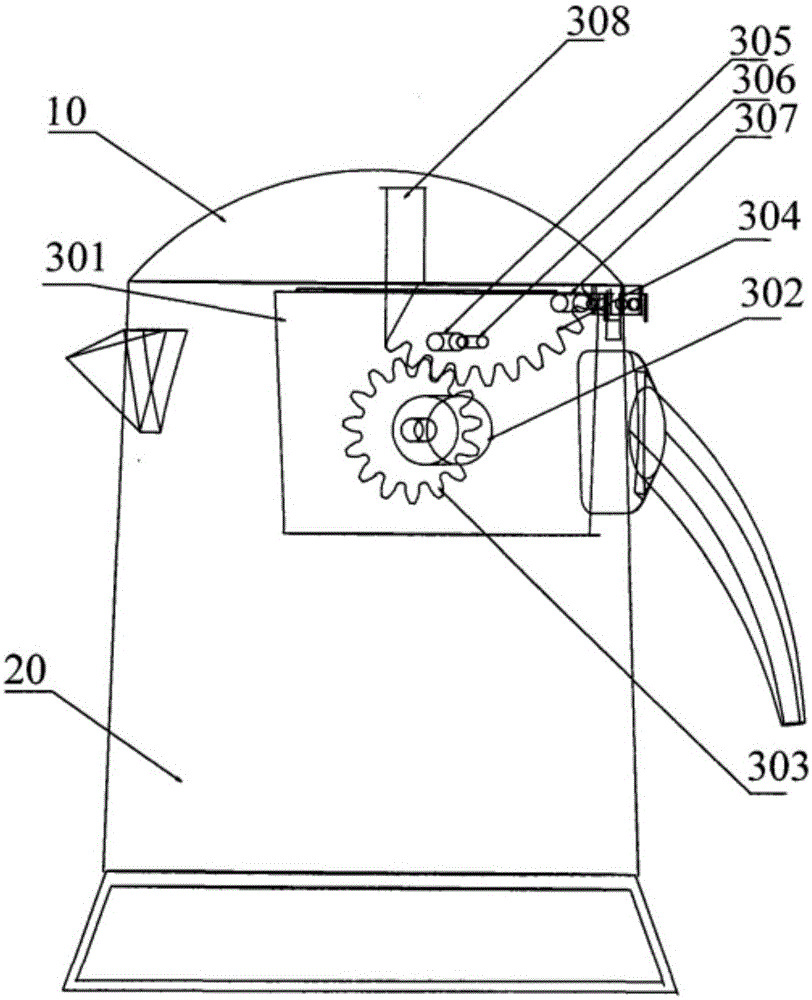

[0027] See figure 1 , figure 2 , image 3 , the present invention provides an electric kettle with an automatic opening and closing lid based on the control of the rate of change of water temperature,

[0028] It includes a kettle body, an automatic opening and closing lid mechanism, a single-chip microcomputer, an electronic switch, a power supply and a temperature sensor, and the kettle body includes a kettle cover and a heating resistor, wherein,

[0029] One end of the electronic switch is used to connect to an external power supply, and the other end is connected to the heating resistor;

[0030] The power supply is connected to the temperature sensor and the single-chip microcomputer respectively;

[0031] The single-chip microcomputer includes a temperature acquisition module, a boiling judgment module and a control module, the temperature acquisition module is used to collect the temperature signal of the temperature sensor, and the boiling judgment module is used ...

Embodiment 2

[0048] See figure 1 , figure 2 , image 3 , the present invention provides an electric kettle with an automatic opening and closing lid based on the control of the rate of change of water temperature,

[0049] It includes a kettle body, an automatic opening and closing lid mechanism, a single-chip microcomputer, an electronic switch, a power supply and a temperature sensor, and the kettle body includes a kettle cover and a heating resistor, wherein,

[0050] One end of the electronic switch is used to connect to an external power supply, and the other end is connected to the heating resistor;

[0051] The power supply is connected to the temperature sensor and the single-chip microcomputer respectively;

[0052] The single-chip microcomputer includes a temperature acquisition module, a boiling judgment module and a control module, the temperature acquisition module is used to collect the temperature signal of the temperature sensor, and the boiling judgment module is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com