Oven heating system for making footwear

A heating system and oven technology, applied in the direction of shoemaking machinery, footwear, application, etc., can solve the problems of affecting the gluing conditions of shoe parts, complicated temperature control, improper temperature control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiment of this case is described in detail as follows in conjunction with the drawings, and the accompanying drawings only illustrate the basic structure of this case in a schematic way. Therefore, only the components related to this case are marked in these diagrams, and the displayed components are not drawn with the number, shape, size ratio, etc. at the time of implementation, and the specifications and sizes at the time of actual implementation are actually an optional design , together first state.

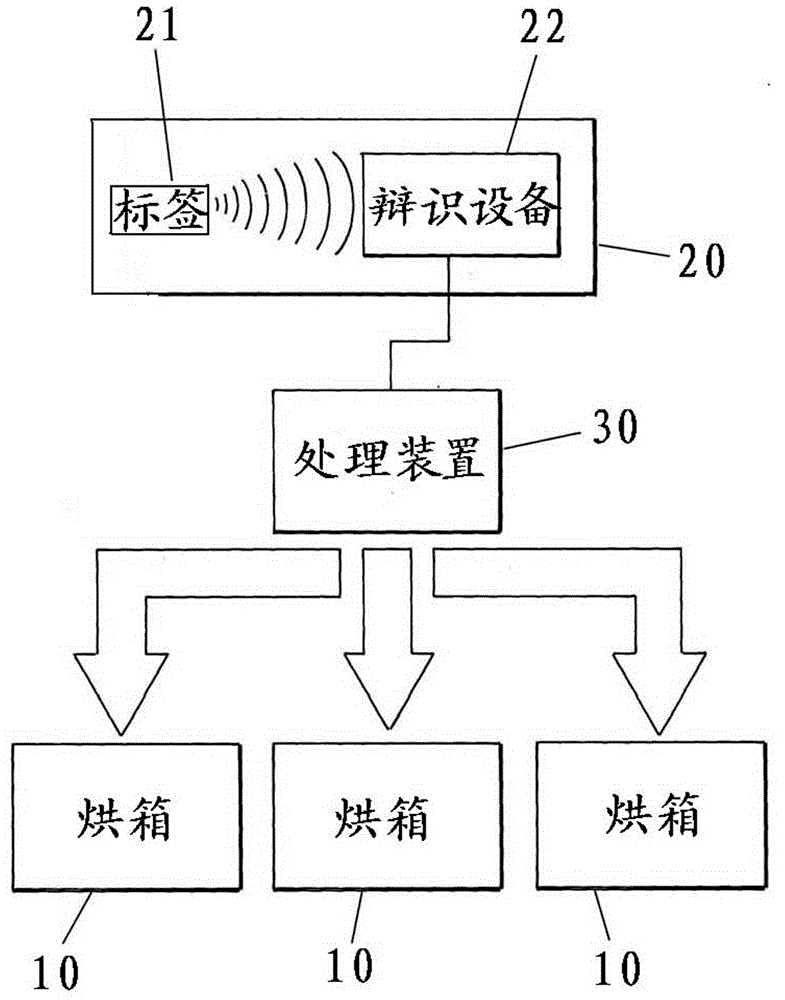

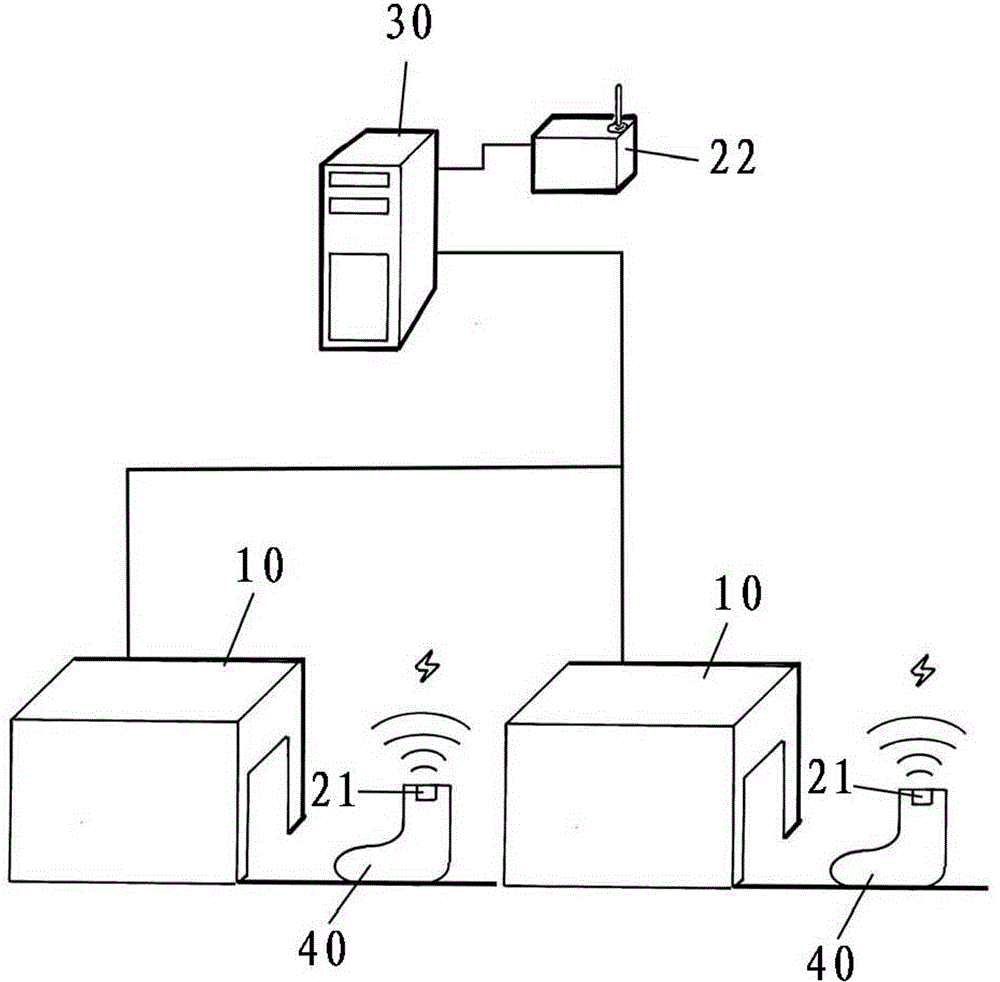

[0015] Please refer to figure 1 The basic structural diagram of the present invention is shown, and figure 2 The illustrated operation flow chart of the present invention. As shown in the drawing, the present invention is composed of more than two ovens 10 , radio frequency identification devices 20 (RFID) and processing devices 30 . in:

[0016] The oven 10 is a heating device used in the field of shoemaking, and is used to heat shoes to a predetermined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com