Unwrapped spandex yarn sock production method

A production method and naked ammonia technology, applied in socks, pantyhose, clothing and other directions, can solve problems such as heavy feeling and strong feeling, and achieve the effects of reducing weight, ensuring warmth retention, and reducing binding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

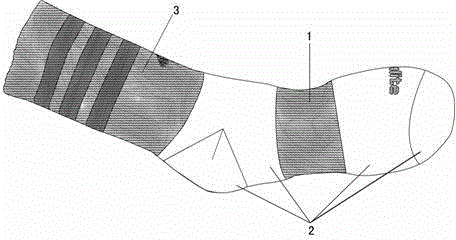

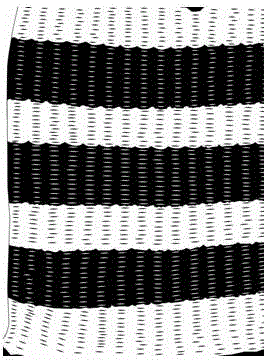

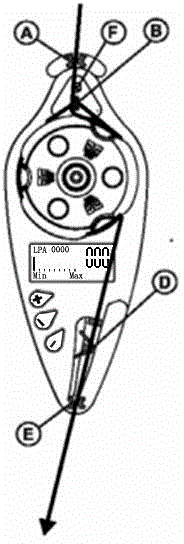

[0009] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown, a production method of naked ammonia socks is characterized in that the specific weaving process is as follows: 1) using the Ronadi G615L model hosiery machine, the number of shuttles is 13, and the number of needles is 144 needles. Socks are woven sequentially; 2) The cuffs are fed with 1.4cm main yarn cotton yarn, and the ULTRAFEEDER super conveyor is used to feed in spandex at the same time, and the main yarn is fed in at a ratio of 1:1 at the same time, and the joints are connected with nylon yarn. Weave 25 circles; the ULTRAFEEDER super conveyor is fixed on the right rear of the hosiery machine, and the conveyor is connected to the main control circuit of the hosiery machine through a signal transmission line. The motor is connected to an independent line to provide power, and the yarn is threaded into the ceramic wire of the conveyor In A, go arou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com